Thick-specification galvanized steel plate for elevator and manufacturing method thereof

A technology of galvanized steel sheet and manufacturing method, which is applied in hot-dip plating process, coating, metal material coating process and other directions, can solve the problems of insufficient adhesion, moiré on the surface of the coating, uneven thickness of the coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

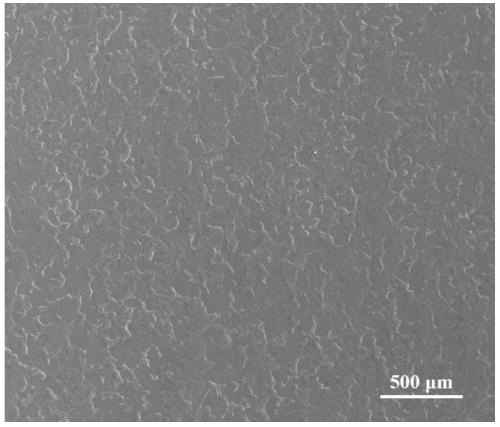

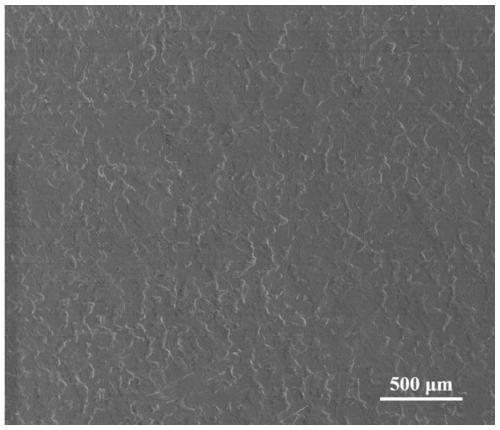

Image

Examples

Embodiment 1

[0056] A thick gauge galvanized steel sheet for an elevator in this embodiment comprises:

[0057] Substrate, which is composed of the following elements in mass percentage: at most 0.060% C, at most 0.040% Si, 0.10-0.25% Mn, at most 0.015% P, at most 0.010% S, at most 0.035% Als, the balance being Fe and unavoidable impurities;

[0058] A hot-dip galvanized layer is formed on the surface of the substrate.

[0059] Specifically, in this embodiment, the substrate is composed of the following mass percentages: 0.040% C, 0.020% Si, 0.15% Mn, 0.010% P, 0.002% S, 0.035% Als, wherein Mn / Si=7.5, C+Si+3( P+S)=0.096%;

[0060] The coating contains 0.15% Al;

[0061] A method for manufacturing a thick-gauge galvanized steel sheet for an elevator in this embodiment, the thickness of the substrate is 1.8mm after being smelted and rolled; it also includes the following processing steps:

[0062] 1. Substrate pretreatment: carry out alkali cleaning, electrolytic degreasing, rinsing and ...

Embodiment 2

[0068] A thick gauge galvanized steel sheet for elevators in this embodiment is further improved on the basis of Example 1, and color-coated on the galvanized steel sheet in Example 1, wherein the passivation temperature during the color-coating process is 80 ℃, the curing furnace temperature is 240 ℃, the surface quality of the galvanized steel plate after color coating reaches FC level, and the hardness of the topcoat reaches HB level. After the reverse impact test, the impact resistance of the coating can reach 15J.

[0069] The galvanized steel plate after the color coating of the present embodiment is carried out neutral salt spray corrosion test, and experimental condition is sodium chloride salt solution mass percentage 5%, pH value 6.5~7.0, spray volume (80cm 2 Area) 1 ~ 2ml / h, spray pressure 90 ~ 100KPa, spray temperature 35 ℃, duration 600h, no obvious corrosion marks on the surface of galvanized steel sheet.

Embodiment 3

[0071] A thick gauge galvanized steel sheet for an elevator in this embodiment comprises:

[0072]Substrate, which is composed of the following elements in mass percentage: at most 0.060% C, at most 0.040% Si, 0.10-0.25% Mn, at most 0.015% P, at most 0.010% S, at most 0.035% Als, the balance being Fe and unavoidable impurities;

[0073] A hot-dip galvanized layer is formed on the surface of the substrate.

[0074] Specifically, in this embodiment, the substrate is composed of the following mass percentages: 0.020% C, 0.040% Si, 0.10% Mn, 0.010% P, 0.002% S, 0.035% Als, wherein Mn / Si=2.5, C+Si+3( P+S)=0.096%;

[0075] The coating contains 0.10% Al;

[0076] A method for manufacturing a thick-gauge galvanized steel sheet for an elevator in this embodiment, the thickness of the substrate is 2.0mm after being smelted and rolled; it also includes the following processing steps:

[0077] 1. Substrate pretreatment: carry out alkali cleaning, electrolytic degreasing, rinsing and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com