Commercial high-efficiency refining deoxidizer and preparation method thereof

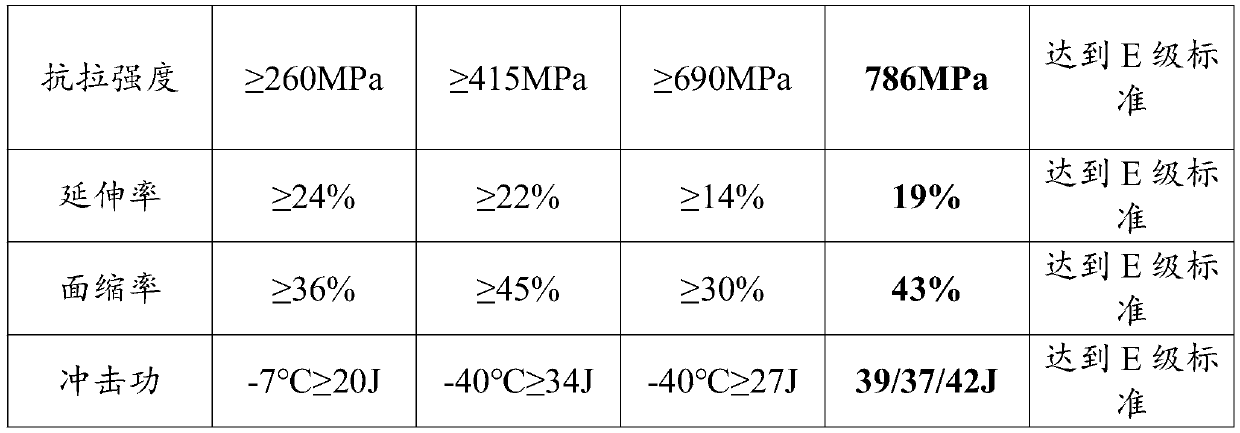

A deoxidizer and high-efficiency technology, applied in the chemical industry, can solve the problems of insufficient deoxidation effect, high cost, and insufficient purification of molten steel, so as to improve cleanliness and mechanical properties, increase toughness and wear resistance, and eliminate nozzle knots. tumor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A commercial high-efficiency refining deoxidizer, comprising the following components by weight percentage:

[0032] Lanthanum 40% and Ce 60%;

[0033] The purity of lanthanum is above 99.9%,

[0034] The purity of cerium is above 99.9%.

[0035] The preparation method of the above-mentioned commercial high-efficiency refining deoxidizer includes the following steps: uniformly mixing various raw materials in a sealed oxygen-free environment, and then filling them into a sealed tank containing an inert gas to obtain the deoxidizer.

Embodiment 2

[0037] A commercial high-efficiency refining deoxidizer, comprising the following components by weight percentage:

[0038] Lanthanum 60% and Ce 40%;

[0039] The purity of lanthanum is above 99.9%,

[0040] The purity of cerium is above 99.9%.

[0041] The preparation method of the above-mentioned commercial high-efficiency refining deoxidizer includes the following steps: uniformly mixing various raw materials in a sealed oxygen-free environment, and then filling them into a sealed tank containing an inert gas to obtain the deoxidizer.

Embodiment 3

[0043] A commercial high-efficiency refining deoxidizer, comprising the following components by weight percentage:

[0044] Lanthanum 45%, cerium 50%, silicon 2%, aluminum 2% and titanium 1%;

[0045] The purity of lanthanum is above 99.9%,

[0046] The purity of cerium is above 99.9%,

[0047] The purity of silicon is above 99.9%,

[0048] The purity of aluminum is above 99.9%,

[0049] The purity of titanium is above 99.9%.

[0050] The preparation method of the above-mentioned commercial high-efficiency refining deoxidizer includes the following steps: uniformly mixing various raw materials in a sealed oxygen-free environment, and then filling them into a sealed tank containing an inert gas to obtain the deoxidizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com