A gr-sio2/nbr material preparation method and ball mill assembly

A ball milling and component technology, applied in the field of rubber mixing, can solve the problems of poor rubber compatibility, weak interaction, and decreased wear resistance, and achieve easy mass production and popularization, low production cost, rolling resistance, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

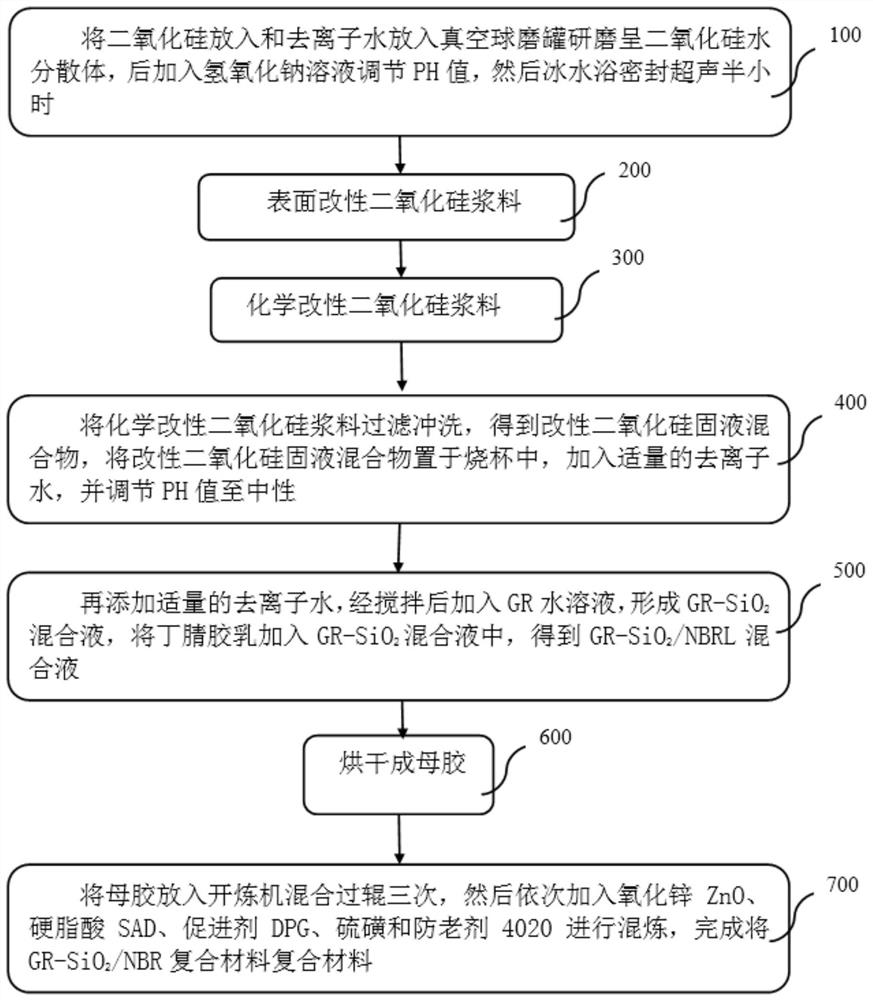

[0040] Such as figure 1 As shown, the present invention provides a GR-SiO 2 / NBR composite material preparation method, comprises the steps:

[0041] S100, put silicon dioxide and deionized water into a vacuum ball mill tank, and use a planetary ball mill to grind to a silicon dioxide aqueous dispersion with a mass fraction of 25 wt%, and then add 2mol / L sodium hydroxide solution to adjust The pH value is 8, and then the ice water bath is sealed and ultrasonicated for half an hour;

[0042] S200, take cetyl-trimethylammonium bromide 12g, use deionized water to configure 60ml aqueous solution of 25wt% and the silicon dioxide aqueous dispersion after the treatment of ultrasonic pH value adjustment, stir and mix, and in a high-speed shearing machine The surface modified silica slurry is formed under the action of

[0043] S300. Then add 200ml of toluene solution to the surface-modified silica slurry, and ultrasonically add toluene sulfur and polyethylene glycol for half an hou...

Embodiment 2

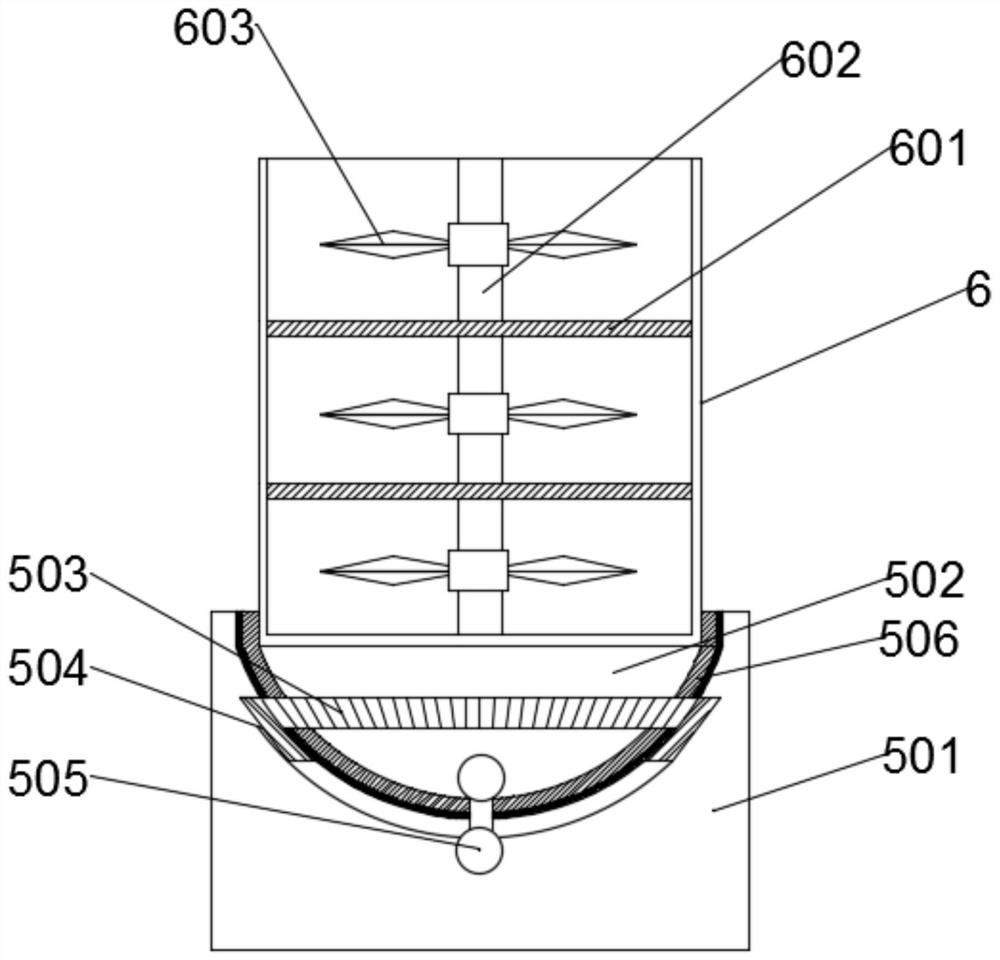

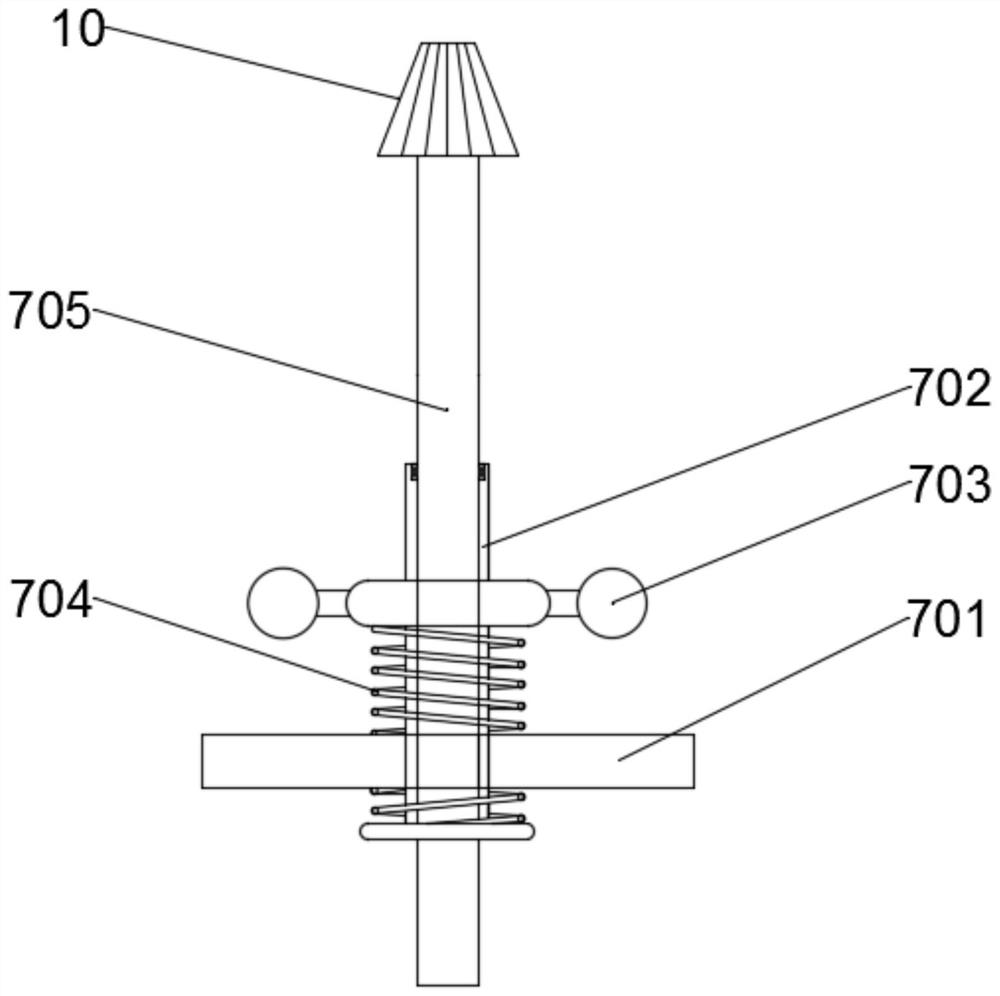

[0057] Such as figure 2 , image 3 and Figure 4 Shown, a kind of GR-SiO used in embodiment 1 provided by the present invention 2 / NBR composite material preparation ball mill assembly, including a base 1 and a mounting groove 2 arranged on the base 1, the mounting groove 2 is provided with a planetary gear 3 driven by a motor, and the planetary gear 3 has at least three star wheels , the star wheel of the planetary wheel 3 is provided with a fixed bracket 4, the fixed bracket 4 is equipped with a grinding tank 6 through a movable hinge device 5, a pressure rod device 7 is installed on the grinding tank 6, and a transfer disc 8 is arranged on the upper part of the grinding tank 6 , and the transfer disc 8 is fixedly connected to the installation groove 2 through a bracket, the transfer disc 8 includes an inner wheel disc 801 and an outer rail ring 802, and the opposite surfaces of the inner wheel disc 801 and the outer rail ring 802 are provided with racks, pressing rods T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com