Inner core filling material for composite insulating cross arm, and preparation method thereof

A technology of composite insulation and filling materials, which is applied in the field of inner core filling materials, can solve the problems of closed porosity and pore size affecting internal field strength, reduction of breakdown voltage of polyurethane, low density insulation performance, etc., to improve physical/electrical properties , Improving the ability to resist voltage breakdown and improving the effect of insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

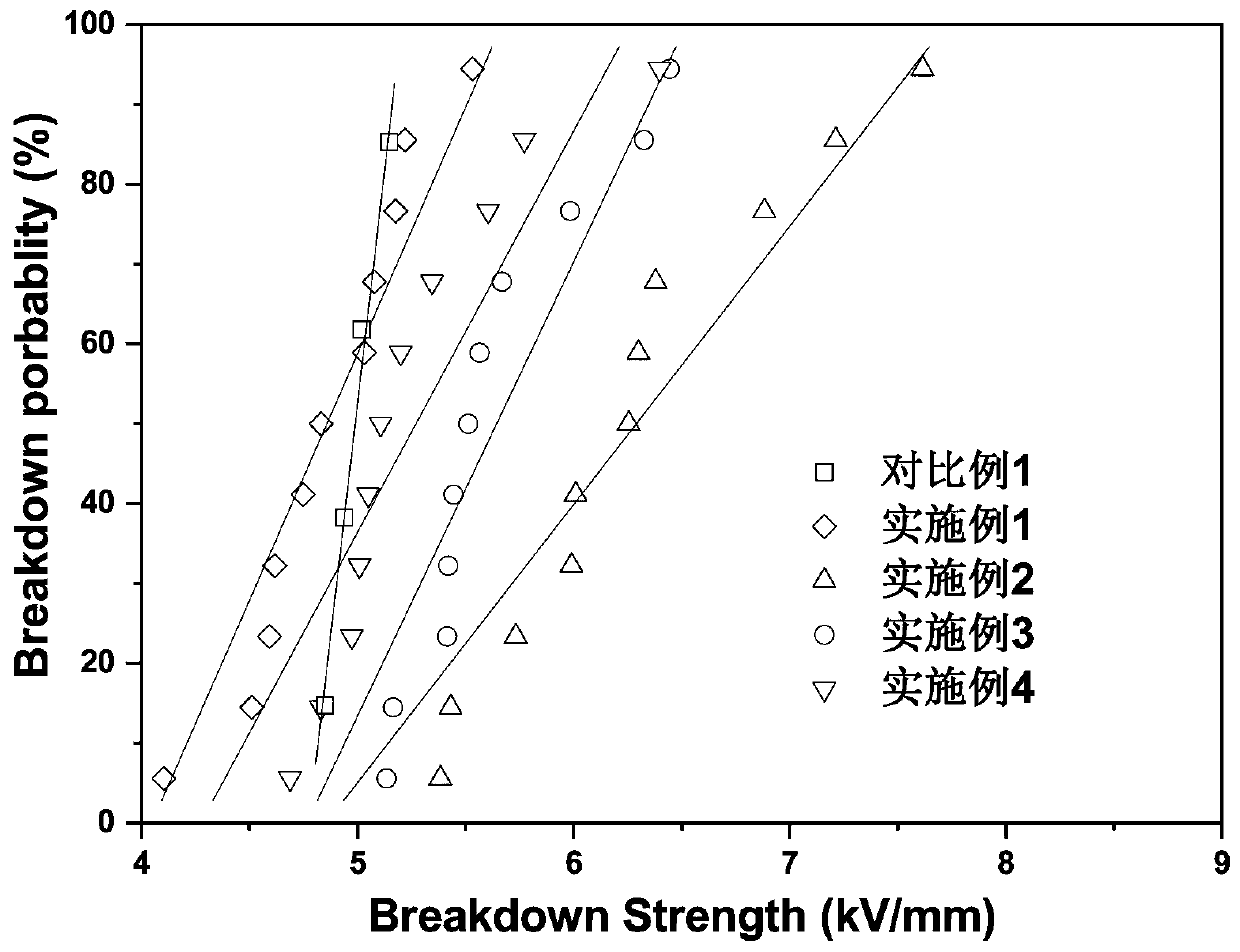

Examples

Embodiment 1

[0033] An inner core filling material for a composite insulating cross arm, comprising the following raw materials in parts by weight:

[0034] Sodium lauryl sulfate is 1 part, ultrapure water is 8 parts, diphenylmethane diisocyanate is 1000 parts, polypropylene glycol 400 is 950 parts, and modified silica is 1 part, and the modified silica The preparation method comprises the following steps:

[0035] (1) Dissolve 19.4g of sodium metasilicate in 200ml of distilled water, add 100mL of NH 4 Cl, mixed evenly;

[0036] (2) Then place the uniformly mixed solution in a water bath, control the temperature of the water bath to 60°C, and stir for 3 hours;

[0037] (3) After stirring, cool to room temperature, filter, and then wash the solid filtrate with distilled water for 3 times;

[0038] (4) Dissolve the cleaned solid filtrate in 100 mL of ethanol, then add 0.01 mol of trimethylchlorosilane, stir well, heat at 80° C. for 3 h, then cool to room temperature, and precipitate a sol...

Embodiment 2

[0049] An inner core filling material for a composite insulating cross arm, comprising the following raw materials in parts by weight:

[0050] Sodium lauryl sulfate is 1.5 parts, ultrapure water is 9 parts, diphenylmethane diisocyanate is 1100 parts, polypropylene glycol 400 is 1000 parts, and modified silicon dioxide is 3 parts, and described modified silicon dioxide The preparation method comprises the following steps:

[0051] (1) Dissolve 25.9g of sodium metasilicate in 300ml of distilled water, add 130mL of NH 4 Cl, mixed evenly;

[0052] (2) Then place the uniformly mixed solution in a water bath, control the temperature of the water bath to 72°C, and stir for 3 hours;

[0053] (3) After stirring, cool to room temperature, filter, and then wash the solid filtrate with distilled water for 3 times;

[0054] (4) Dissolve the cleaned solid filtrate in 130 mL of ethanol, then add 0.02 mol of trimethylchlorosilane, stir well, heat at 80° C. for 3 h, then cool to room tempera...

Embodiment 3

[0065] An inner core filling material for a composite insulating cross arm, comprising the following raw materials in parts by weight:

[0066] Sodium lauryl sulfate is 2 parts, ultrapure water is 10 parts, diphenylmethane diisocyanate is 1150 parts, polypropylene glycol 400 is 1000 parts, and modified silicon dioxide is 5 parts, and described modified silicon dioxide The preparation method comprises the following steps:

[0067] (1) Dissolve 31.5g of sodium metasilicate in 400ml of distilled water, add 150mL of NH 4 Cl, mixed evenly;

[0068] (2) Then place the uniformly mixed solution in a water bath, control the temperature of the water bath to 75°C, and stir for 3 hours;

[0069] (3) After stirring, cool to room temperature, filter, and then wash the solid filtrate with distilled water for 3 times;

[0070] (4) Dissolve the cleaned solid filtrate in 250 mL of ethanol, then add 0.04 mol of trimethylchlorosilane, stir evenly, heat at 80° C. for 3 h, cool to room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com