A method and device for preparing aromatics from synthesis gas

A synthesis gas and aromatics technology, applied in the chemical industry, can solve the problems of low olefin yield, long reaction process, and complex aromatics preparation method, and achieve the effects of low olefin content, process reduction, and process adaptability enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

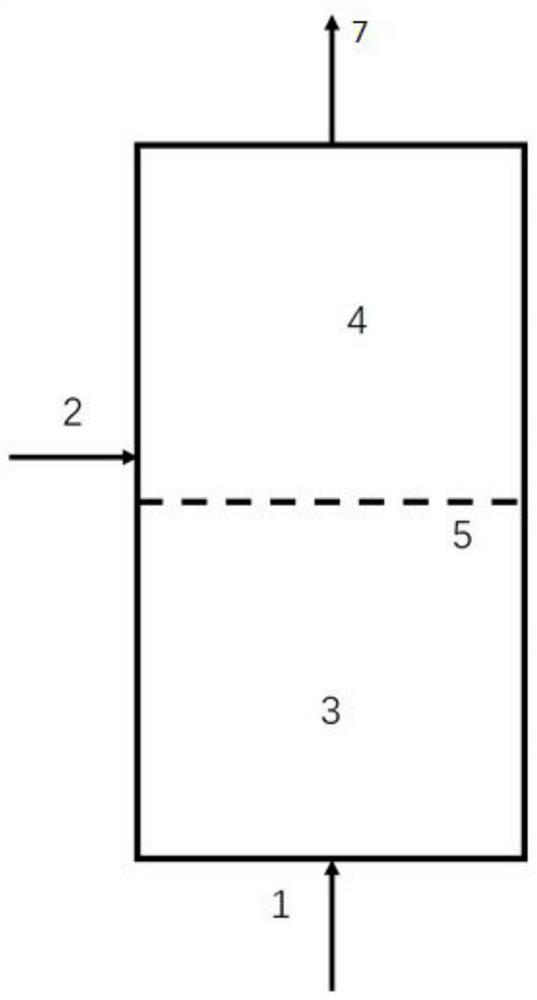

[0025] use figure 1 Shown reaction device, first section reaction zone 3 and second section reaction zone 4 are the reactor of fixed bed, and catalyst (50%Fe-30%Zn-20%Na 2 O) placed in the first stage of reaction zone 3, the catalyst (ZSM-5) is placed in the second stage of reaction zone 4. A perforated plate 5 is arranged between the two sections so that the catalysts in the two sections are not exchanged or mixed.

[0026] Feed H into the first stage reaction zone 3 through the synthesis gas inlet 1 2 Mixed gas with / CO molar ratio of 2:1, at 2MPa, 450℃, volume space velocity of 10000h -1 olefin synthesis reaction. When the CO conversion rate is 90% and the olefin selectivity is 50%, the mixed gas obtained from the outlet of the first-stage reaction zone 3 enters the second-stage reaction zone 4 . At the same time, feed benzene into the second-stage reaction zone through benzene or toluene inlet 2, and control the molar ratio of benzene to total olefins in the mixed gas ...

Embodiment 2

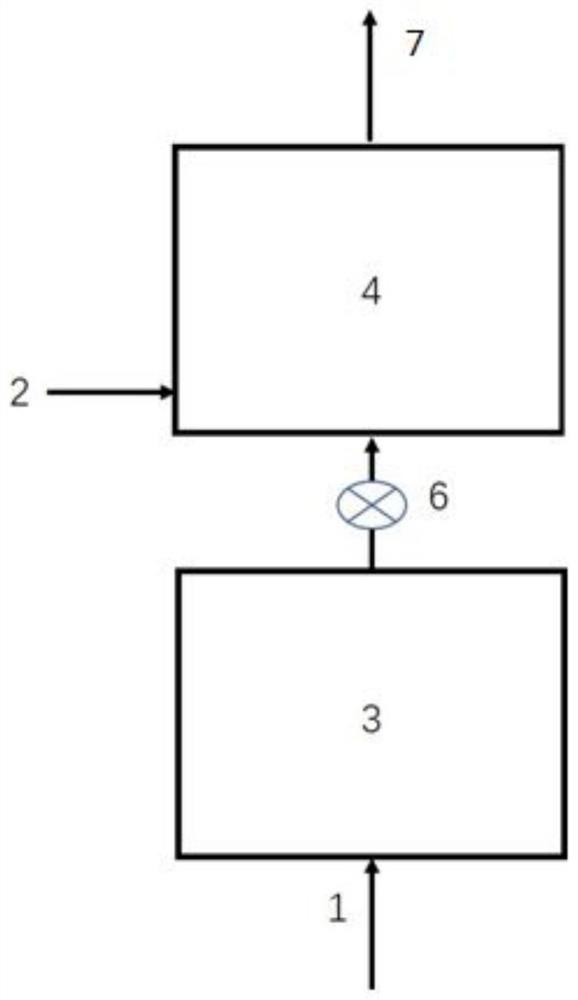

[0028] use figure 2 Shown reaction device adopts the reactor that the first stage reaction zone 3 and the second stage reaction zone 4 are fluidized beds, and the catalyst (20%Ni-20%La-20%Ga-40%K 2 O) packing the first stage reaction zone 3, catalyst (35%ZSM-5-30%Al 2 o 3 -25% SiO2 2 ) device in the second stage reaction zone 4. A valve element 6 is set between the two sections, so that the catalysts in the two sections are not exchanged or mixed.

[0029] Feed H into the first stage reaction zone 3 through the synthesis gas inlet 1 2 Mixed gas with / CO molar ratio of 1:1, at 5MPa, 250℃, and volume space velocity of 500h -1 olefin synthesis reaction. When the CO conversion rate is 50% and the olefin selectivity is 90%, the mixed gas obtained from the outlet of the first-stage reaction zone 3 enters the second-stage reaction zone 4 . At the same time, feed benzene into the second-stage reaction zone 4 through the benzene or toluene inlet 2, and control the molar ratio o...

Embodiment 3

[0031] use figure 2 The shown reaction device adopts the reactor in which the first stage reaction zone 3 and the second stage reaction zone 4 are both moving beds, and the catalyst (15%Co-5%Ag-40%Mn-40%CaO) is placed in the first stage section, the catalyst (30% β molecular sieve-20% ZSM-22-50% Al2 o 3 ) placed in the second paragraph. A valve element 6 is set between the two sections, so that the catalysts in the two sections are not exchanged or mixed.

[0032] Feed H into the first stage reaction zone 3 through the synthesis gas inlet 1 2 Mixed gas with / CO molar ratio of 5:1, at 0.5MPa, 350℃, volume space velocity of 3000h -1 olefin synthesis reaction. When the CO conversion rate is 60% and the olefin selectivity is 75%, the mixed gas obtained from the outlet of the first-stage reaction zone enters into the second-stage reaction zone 4 . At the same time, toluene is introduced into the second stage reaction zone 4 through the benzene or toluene inlet 2, and the mola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com