Treatment process for realizing urban sewage denitrification and phosphorous removal coupled sludge fermentation by two-stage sequencing batch reactor

A sequencing batch reactor and urban sewage technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, water treatment parameter control, etc., can solve problems such as environmental pollution, difficult and difficult transformation of sewage plants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

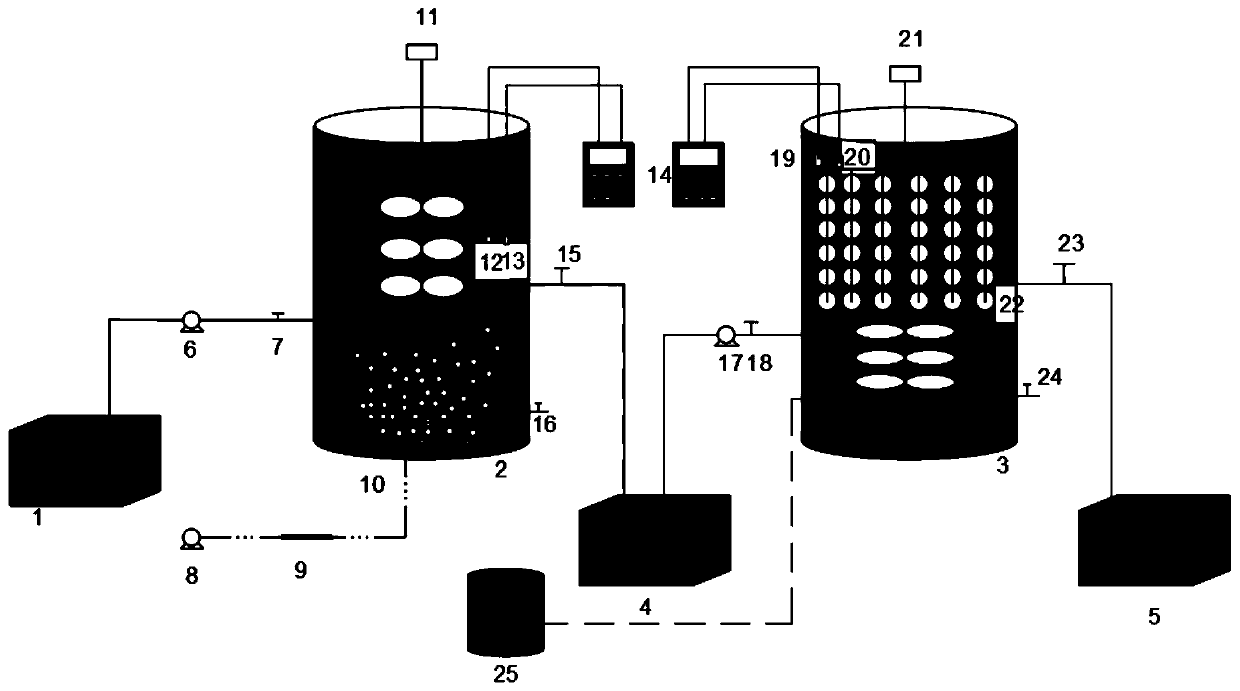

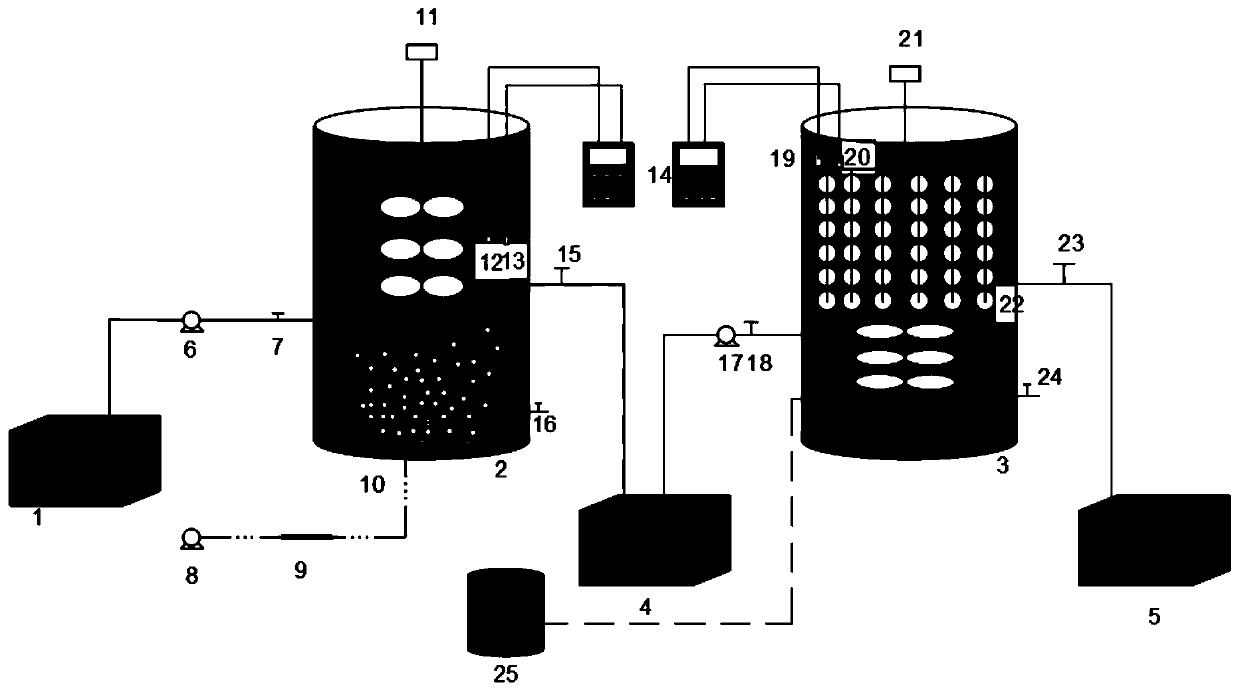

[0026] combined with figure 1 The present invention is described in further detail.

[0027]The two-stage sequencing batch reactor realizes the treatment process of urban sewage denitrification and phosphorus removal coupled with sludge fermentation, and is characterized in that it includes an inlet tank (1), a biologically enhanced phosphorus removal coupled partial short-range nitrification reactor EBPR-PN-SBR ( 2), intermediate water tank (4), anaerobic ammonium oxidation coupling sludge fermentation and denitrification reactor ASFD-SBR (3), water outlet tank (5); water inlet tank (1) is connected with water inlet by water inlet pump (6) The valve (7) is connected with the bio-enhanced phosphorus removal coupled partial short-range nitrification reactor EBPR-PN-SBR (2); the bio-enhanced phosphorus removal coupled partial short-range nitrification reactor EBPR-PN-SBR (2) includes a water quality analyzer WTW (14 ) and DO probe (12), pH probe (13) and an aeration system and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com