SBR water treating device

A technology of water treatment device and water inlet pipe, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, sedimentation treatment, etc., and can solve the problems of low volume utilization rate and affecting treatment efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

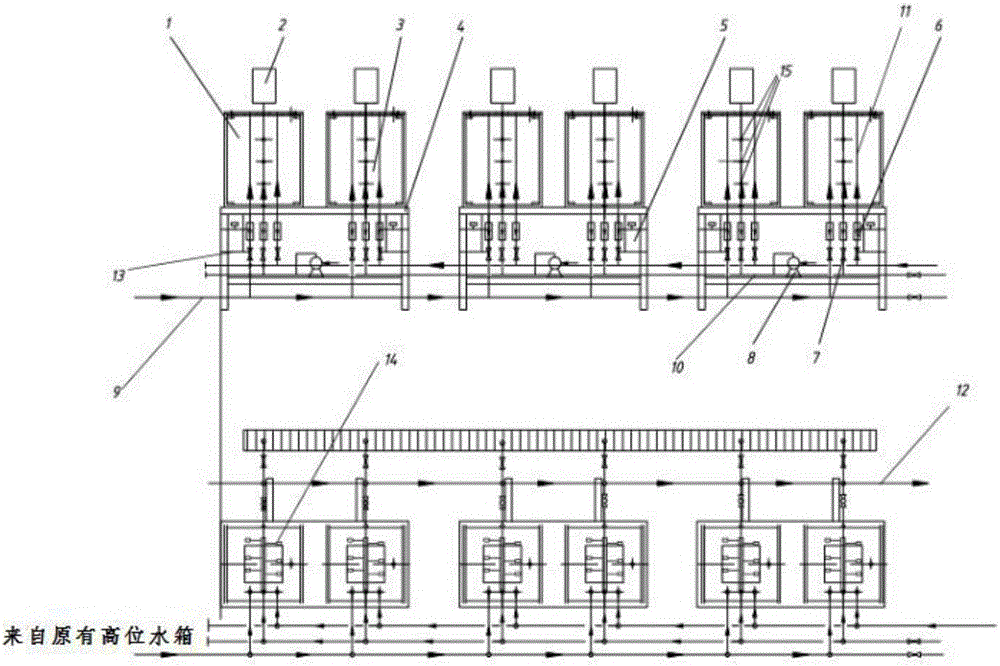

[0015] See figure 1 As shown, the technical solution adopted in this embodiment is: SBR water treatment device, which includes several reactors 1, electric motors 2, stirring paddles 3, brackets 4, speed regulators 5, flow meters 6, ball valves 7, and air pumps 8. , Water inlet pipe 9, aeration pipe 10, sludge return pipe 11, sewage pipe 12, governor box 13, aeration head 14, drain 15; the upper end of the support 4 is provided with several reactors 1, several reactors 1. Stirring paddles 3 are installed inside. The upper end of the stirring paddles 3 is connected with a motor 2. The governor 5 is arranged in the governor box 13, and the governor box 13 is fixedly installed on the bracket 4. Several reactors 1 are provided There is a sludge return pipe 11, a flow meter 6 is provided on the sludge return pipe 11, a water inlet pipe 9 and an aeration pipe 10 are provided at the bottom of the support 4, and an aeration head 14 and an aeration head 14 are provided on the aeration p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com