Alkali metal salt assisted ultrasonic stripping processed graphene as well as preparation method and application thereof

An alkali metal salt, ultrasonic exfoliation technology, applied in the direction of graphene, nano carbon, etc., can solve the problem of low exfoliation efficiency of ultrasonic exfoliation graphene, and achieve the effect of excellent electrochemical performance, increased active sites, and improved yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

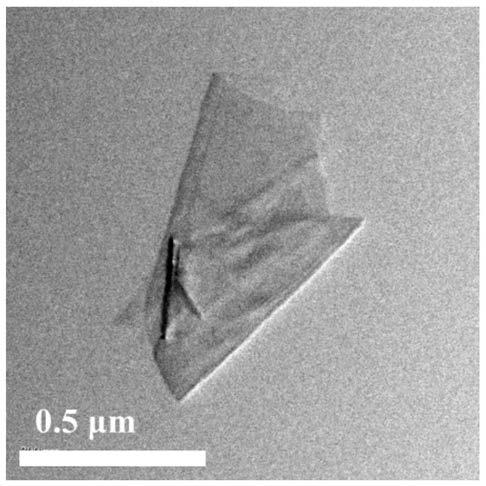

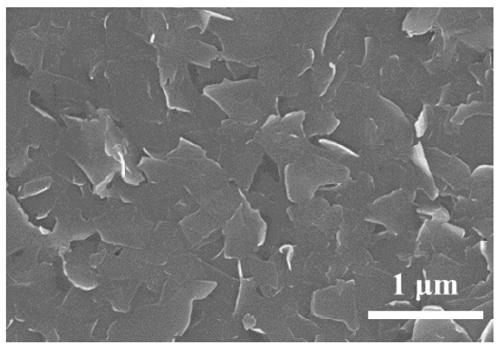

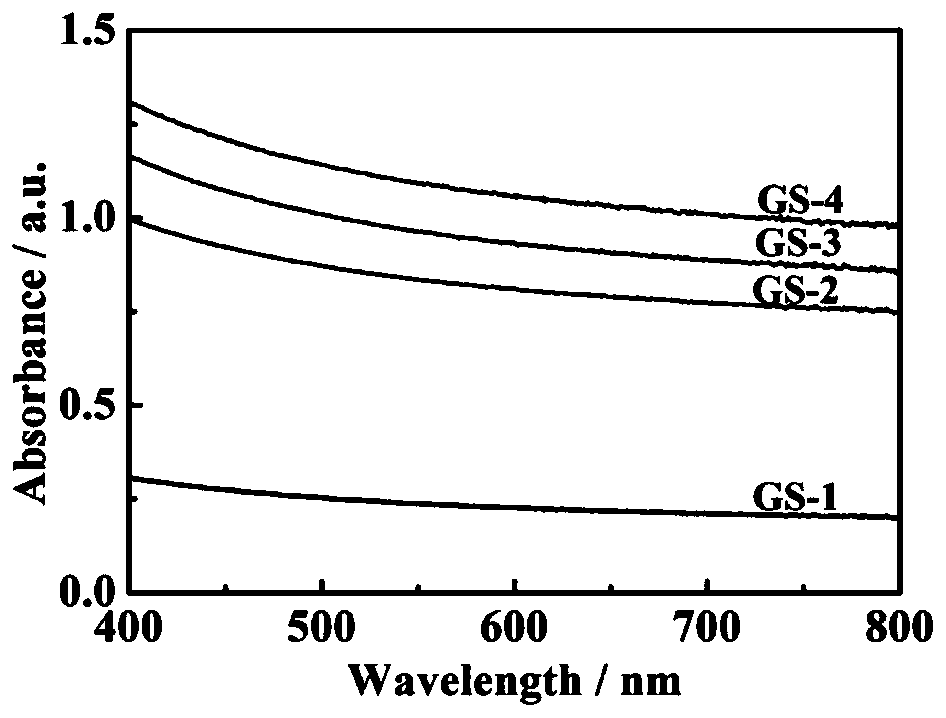

[0032] Add graphite powder and sodium pyrophosphate into the sample bottle filled with N-methylpyrrolidone, the concentration of graphite powder in the solvent is 20mg mL -1 , the concentration of sodium pyrophosphate in the solvent is 20mg mL -1 . Sonicate in a sonicator with a power of 100W for 2h to obtain a suspension. The resulting mixture was centrifuged at a centrifugal speed of 2000r / min for 20min, and the supernatant was taken to obtain a graphene suspension. figure 1 and figure 2 Respectively, the transmission electron micrograph and the scanning electron micrograph of the graphene nanosheets peeled out by the method of Example 1 ultrasonically. Thin nanosheets with uniform size can be observed, indicating that the graphite powder was successfully exfoliated as graphene.

[0033] The sodium-salt-assisted ultrasonically exfoliated graphene-modified glassy carbon electrode prepared above was used as a working electrode, and a commonly used three-electrode system was...

Embodiment 2

[0035] Graphite powder and sodium phosphate are added in the sample bottle that N-methylpyrrolidone is housed, and the concentration of graphite powder in solvent is 20mg mL -1 , the concentration of potassium phosphate in the solvent is 20mg mL -1 . Sonicate in a sonicator with a power of 100W for 2h to obtain a mixed solution. The resulting mixture was centrifuged at a centrifugal speed of 2000r / min for 20min, and the supernatant was taken to obtain a graphene suspension.

Embodiment 3

[0037] Add graphite powder and potassium pyrophosphate into the sample bottle filled with N,N-dimethylformamide, the concentration of graphite powder in the solvent is 50mg mL -1 , the concentration of sodium pyrophosphate in the solvent is 50mg mL -1 . Sonicate for 40h in a sonicator with a power of 600W to obtain a mixed solution. The resulting mixed solution was centrifuged at a centrifugal speed of 8000r / min for 40min, and the supernatant was taken to obtain a graphene suspension.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com