Welding platform with adjustable device

A welding platform and adjustable technology, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor adjustability, inability to fix the device, inability to rotate cylindrical tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

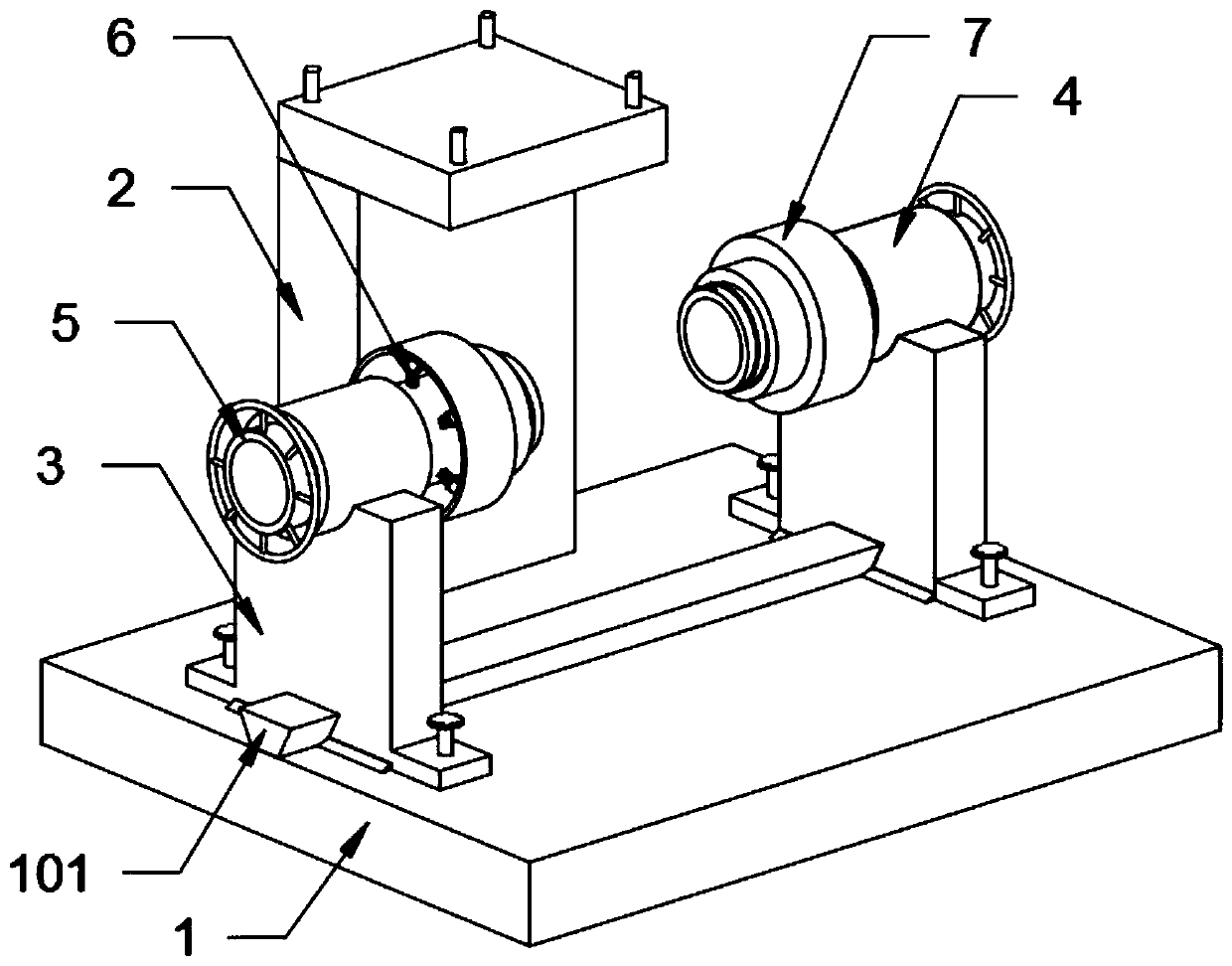

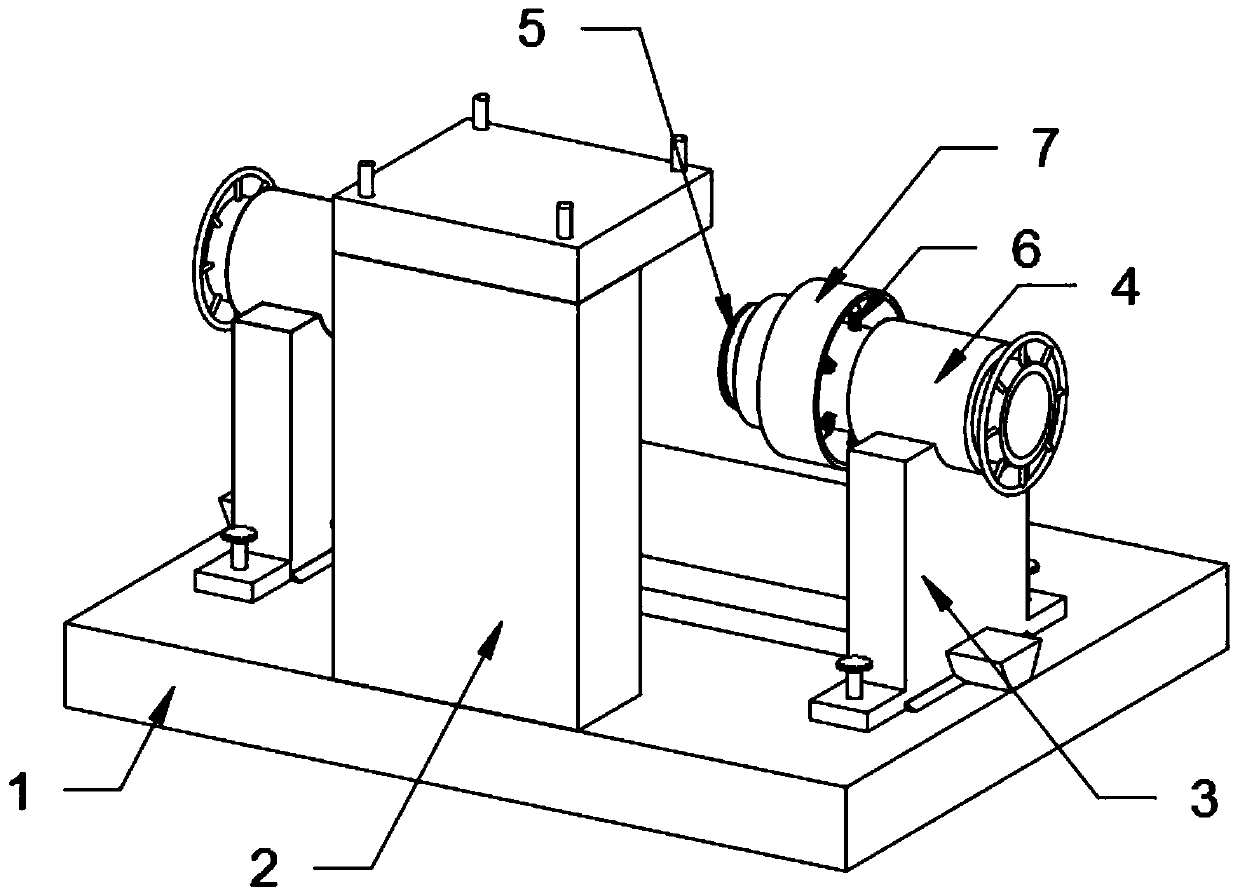

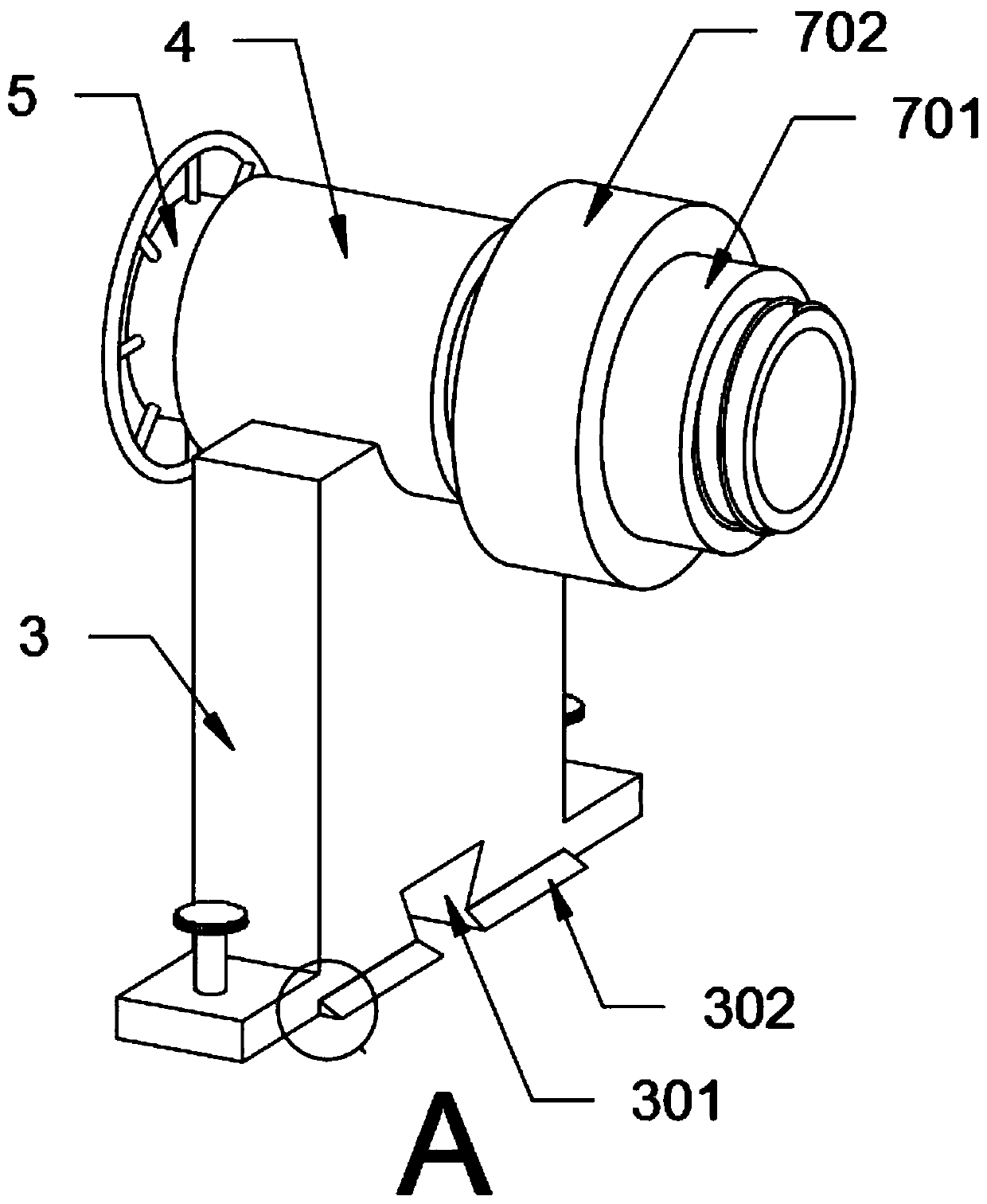

[0032] as attached figure 1 to attach Figure 7 Shown:

[0033] The invention provides a welding platform with an adjustable device, including a fixed plate 1, a trapezoidal sliding column 101, a welding machine mounting seat 2, a clamp seat 3, a trapezoidal groove 301, a cylindrical iron 302, a fixed cylindrical tube 4, and a cylindrical tube 5. Clamp claw structure 6, clamp rod 601, clamp head 602, iron stopper 603, spring 604, iron ball 605, locking structure 7 and tapered groove 701; A welding machine mounting seat 2; a fixed cylindrical tube 4 is welded on the top surface of the fixture seat 3, and a cylindrical tube 5 is rotatably connected inside the fixed cylindrical tube 4; the position on the right side of the outer wall of the cylindrical tube 5 is in a rectangular array The elastic shape is provided with six clamp claw structures 6 .

[0034] Reference as figure 1 , a trapezoidal sliding column 101 is welded at the center of the top surface of the fixed plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com