Spring making machine feed device

A tool feeding device and manufacturing machine technology, applied in the direction of manufacturing springs, static electricity, electrical components, etc. from wires, can solve problems that affect the normal processing of equipment, seal ring changes, and affect the production quality of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

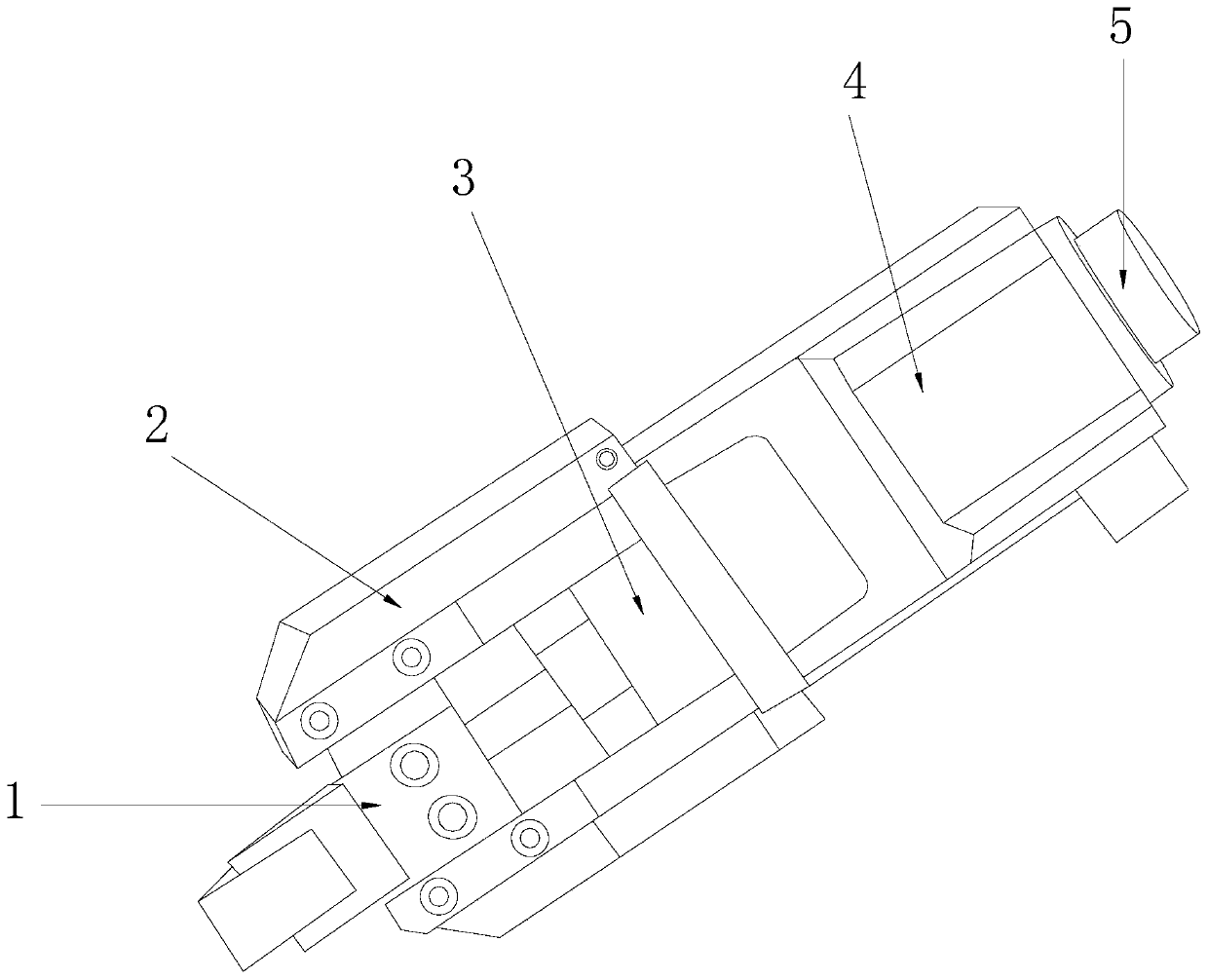

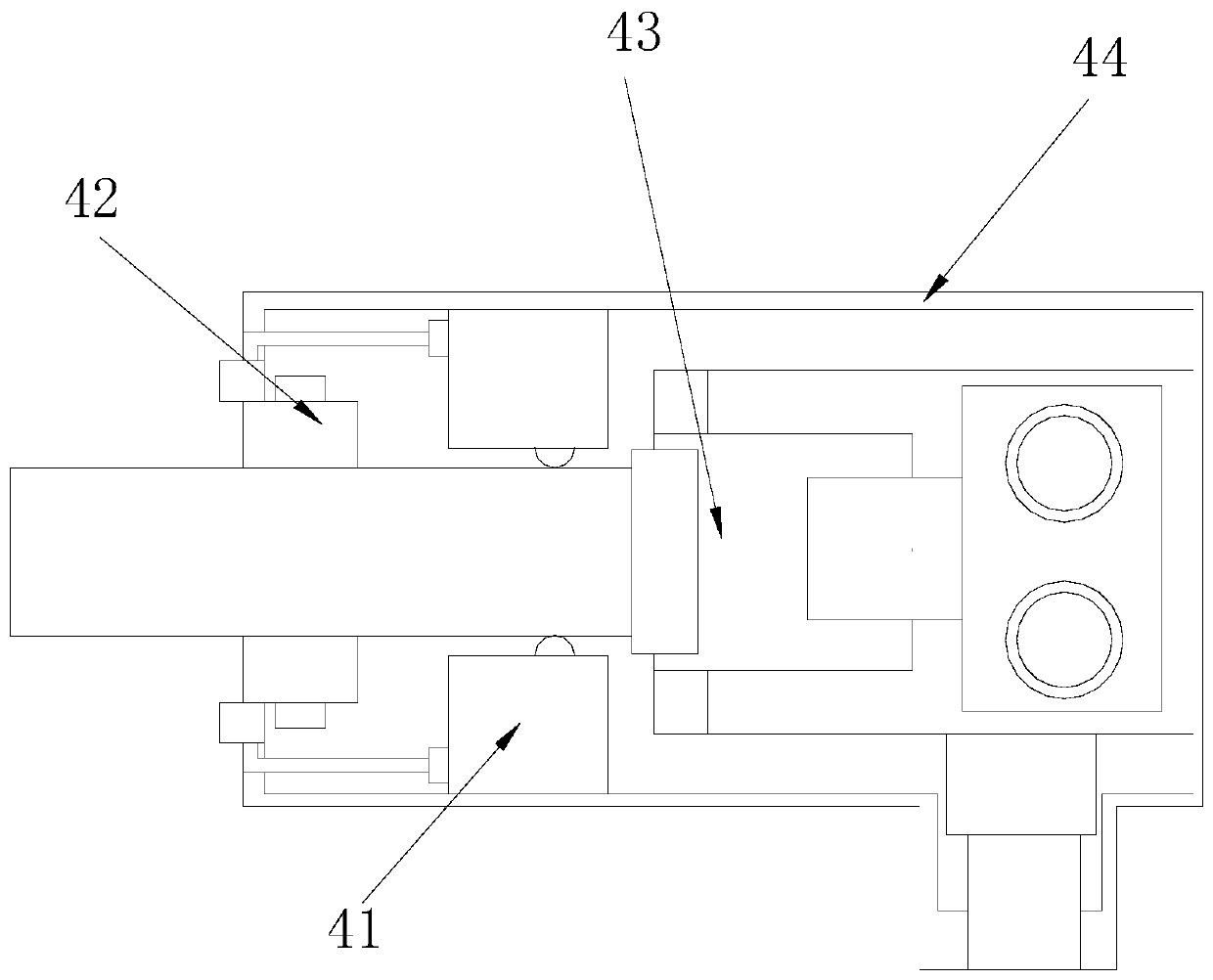

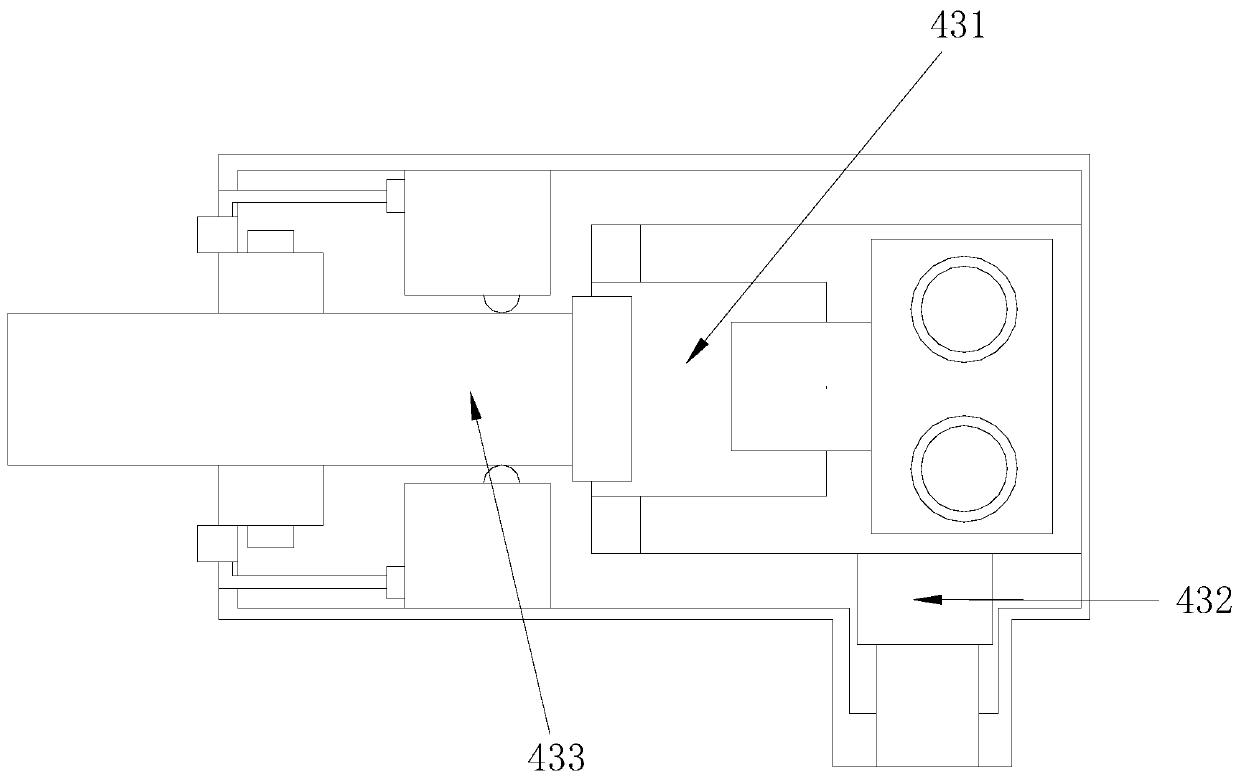

[0030] see Figure 1-Figure 7, the present invention provides a tool feeding device for a spring manufacturing machine. Its structure includes a tool connecting head 1, a side block 2, a push connecting block 3, a knife feeding mechanism 4, and a connecting block 5. The right end of the tool connecting head 1 is horizontally embedded in the push connecting block. In the middle of the left end of 3, the side blocks 2 are provided at the upper and lower ends of the tool connector 1, and the side blocks 2 are provided with two, which are respectively welded with the upper and lower ends of the push connecting block 3. The push connecting block 3 The right end of the feeding mechanism 4 is welded with the left end of the feeding mechanism 4. The right end of the feeding mechanism 4 and the left end of the connecting block 5 are integrated structures. 43. Housing 44, there are two static elimination components 41, which are respectively movably connected to the upper and lower ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com