Preparing method of surface-defect-mode-modified metal sulfide catalyst

A metal sulfide and catalyst technology, applied in the field of metal sulfide catalyst preparation, can solve problems such as difficulty in activating nitrogen molecules, and achieve the effects of improving nitrogen fixation efficiency, simple synthesis route and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

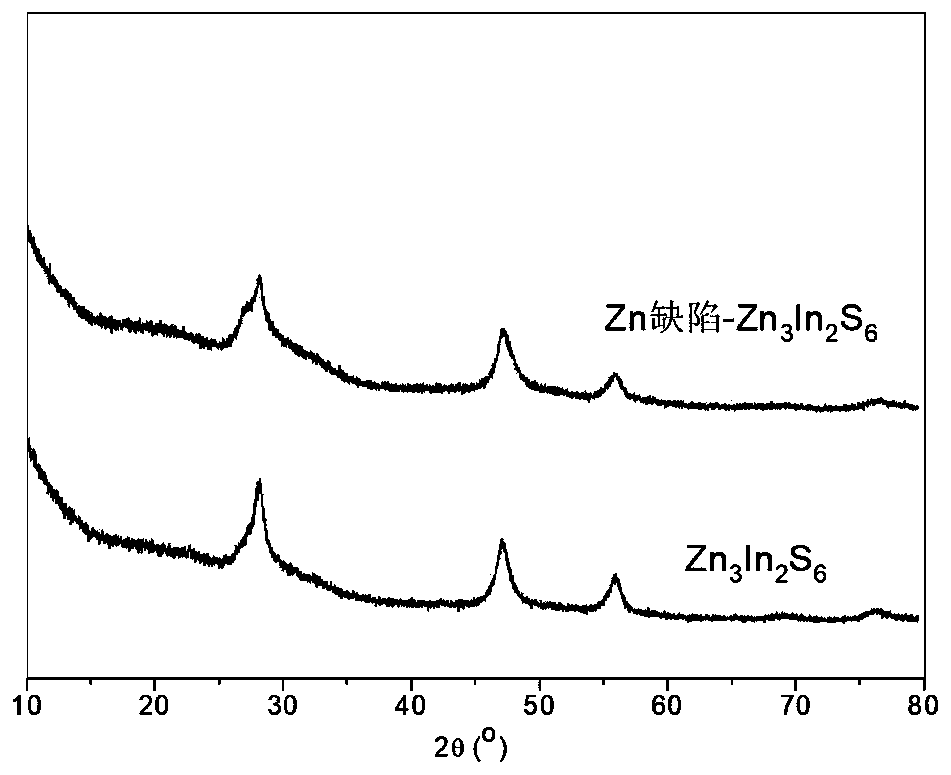

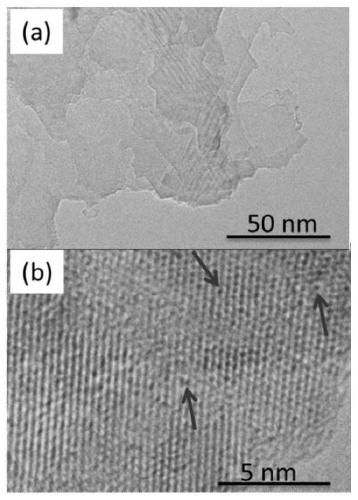

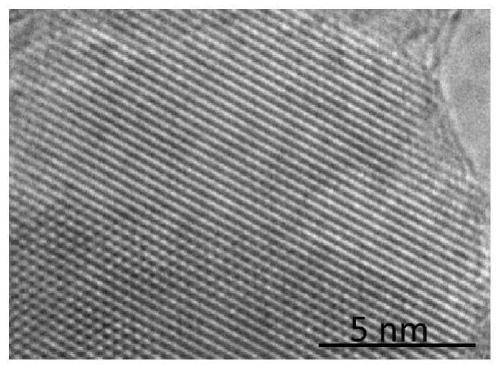

[0029] This embodiment prepares Zn deficiency-Zn according to the following steps 3 In 2 S 6 (when x=3) catalyst:

[0030] Step 1, weigh 1.5mmol of zinc nitrate, 1mmol of indium nitrate hydrate and 3mmol of cysteine in a beaker filled with 60mL of deionized water, and stir to dissolve them;

[0031] Step 2, transfer the mixture in step 1 to a 100ml polytetrafluoroethylene liner, seal it, heat it with water at 200°C, and after 20 hours, wash it with deionized water and dry it in vacuum to obtain the Zn defect-Zn 3 In 2 S 6 catalyst.

[0032] Other surface defect-modified catalysts (surface defect-modified transition metal dichalcogenides (TMDs)) Zn defect-Zn x In 2 S 3+x (x=1-5) and the like can be prepared by changing the raw materials and process conditions and adopting the above-mentioned preparation method. Among them, the raw materials of metal elements are their nitrates, and the ratio of raw materials adopts the atomic composition ratio of TMDs, and other cond...

Embodiment 2

[0034] This embodiment prepares Zn-deficient ZnIn according to the following steps 2 S 4 (when x=1) catalyst:

[0035] Zn-deficient ZnIn 2 S 4 The synthesis of: 0.5mmol zinc nitrate, 1mmol hydrated indium nitrate and 2mmol cysteine; other conditions remain unchanged.

[0036] With the Zn defect-Zn in embodiment 1 3 In 2 S 6 The synthesis method of the catalyst is the same, the difference is that the input amount ratio of the raw materials is changed.

Embodiment 3

[0038] This embodiment prepares Zn-deficient Zn according to the following steps 2 In 2 S 5 (when x=2) catalyst:

[0039] Zn-deficient ZnIn 2 S 5 The synthesis of: 1mmol zinc nitrate, 1mmol hydrated indium nitrate and 2.5mmol cysteine; other conditions remain unchanged.

[0040] With the Zn defect-Zn in embodiment 1 3 In 2 S 6 The synthesis method of the catalyst is the same, the difference is that the input amount ratio of the raw materials is changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com