Gas-liquid separator

A gas-liquid separator and wire mesh technology, applied in separation methods, dispersed particle separation, dispersed particle filtration, etc., can solve problems such as difficult to solve corrosion, separator lining corrosion, etc., to avoid deformation and aging, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0028] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

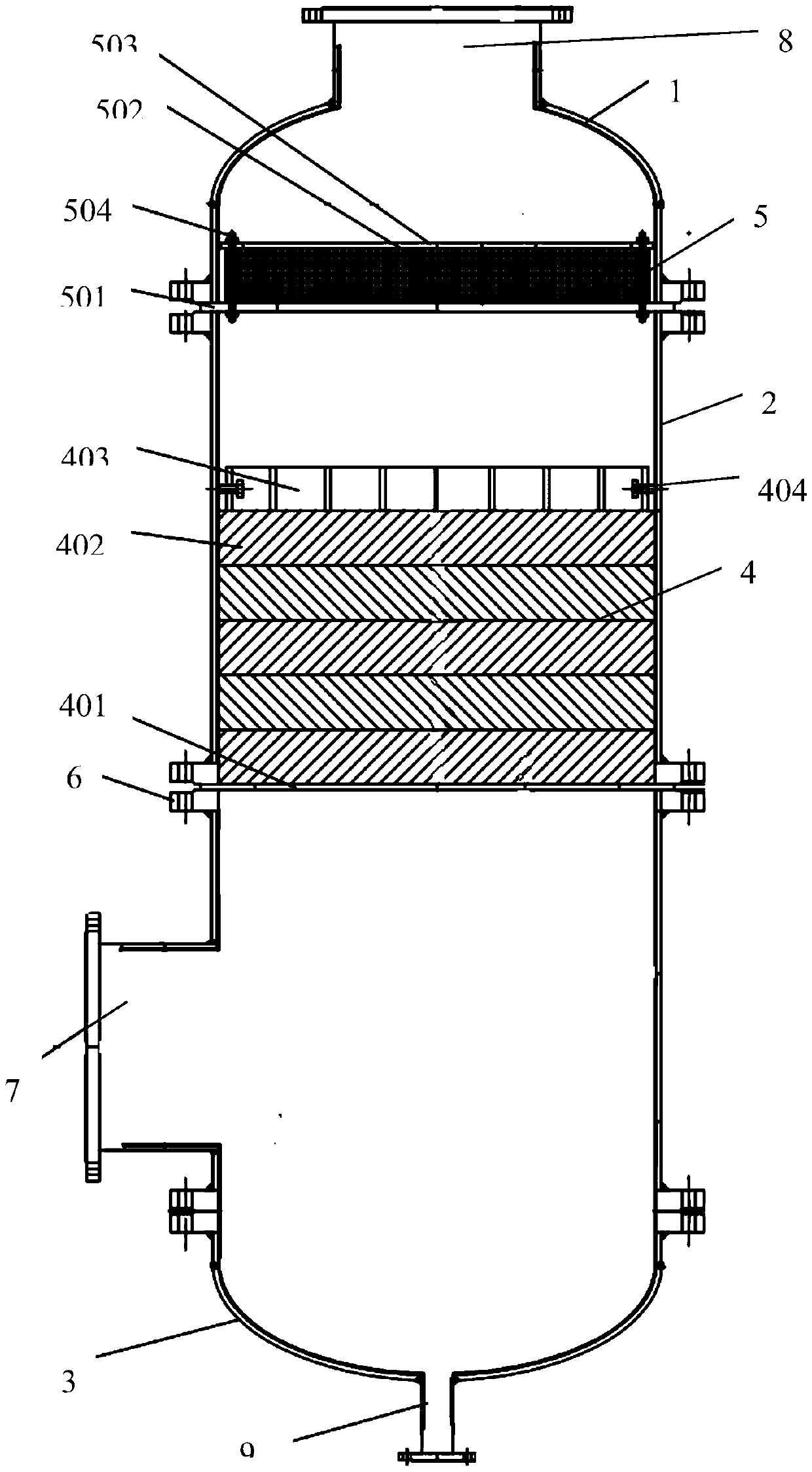

[0029] The invention provides a gas-liquid separator, comprising:

[0030] The cylinder body 2 is provided with a gas-liquid mixture inlet 7 on the side of its lower end; the cylinder body 2 is formed into a hollow cylindrical shape for accommodating the structured packing device 4, and the gas-liquid mixture inlet 7 is used for separating the The gas-liquid mixture can enter the separator.

[0031] The upper head 1 is detachably connected to the upper end of the cylinder 2, and the top end is provided with a gas phase outlet 8; the upper head 1 is used to accommodate the screen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com