Lightweight dense insulating bus groove

A busway, light-weight technology, applied in the installation of busbars, cooling busbar devices, fully enclosed busbar devices, etc., can solve the problems of high cost of production equipment, unreached structure, simple process, large workshop area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

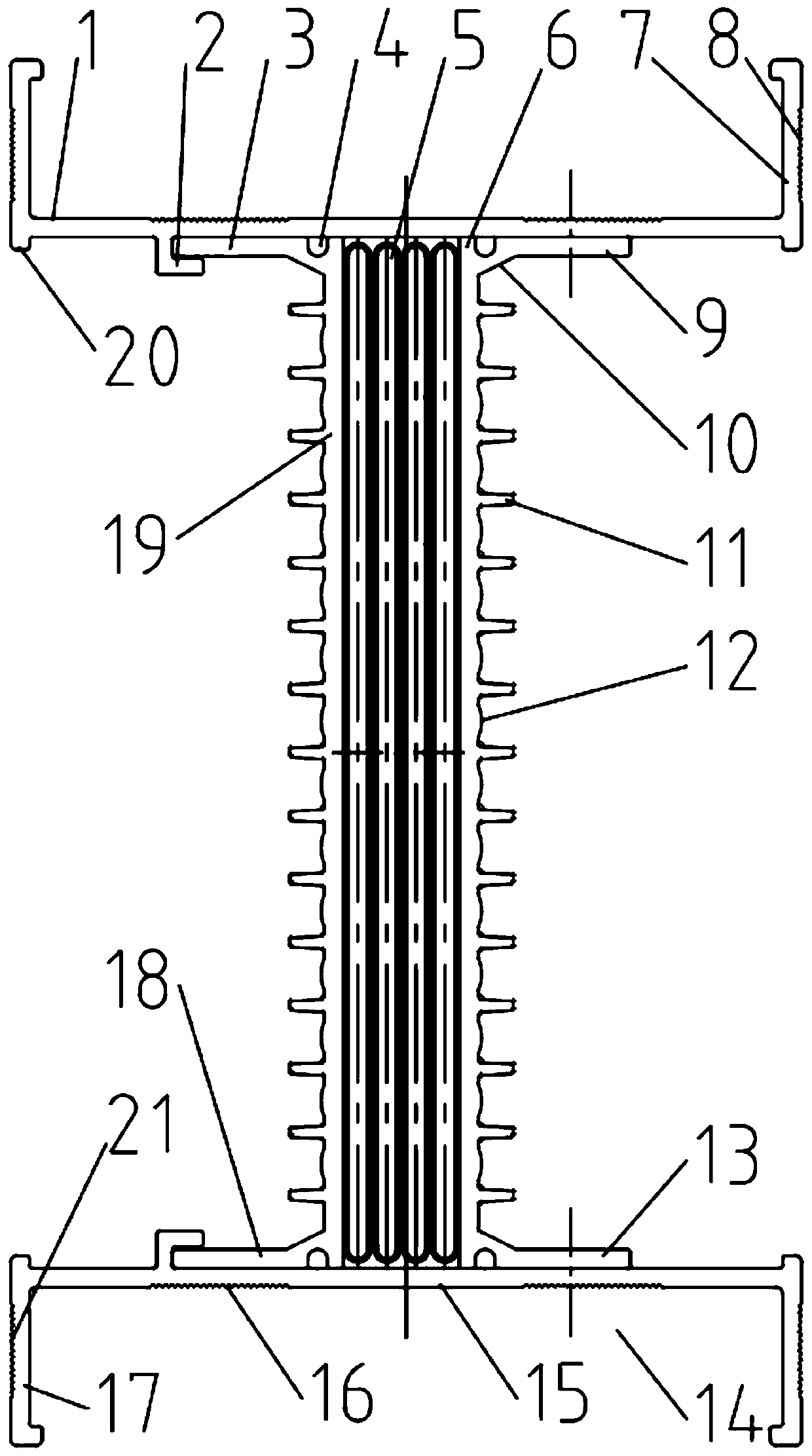

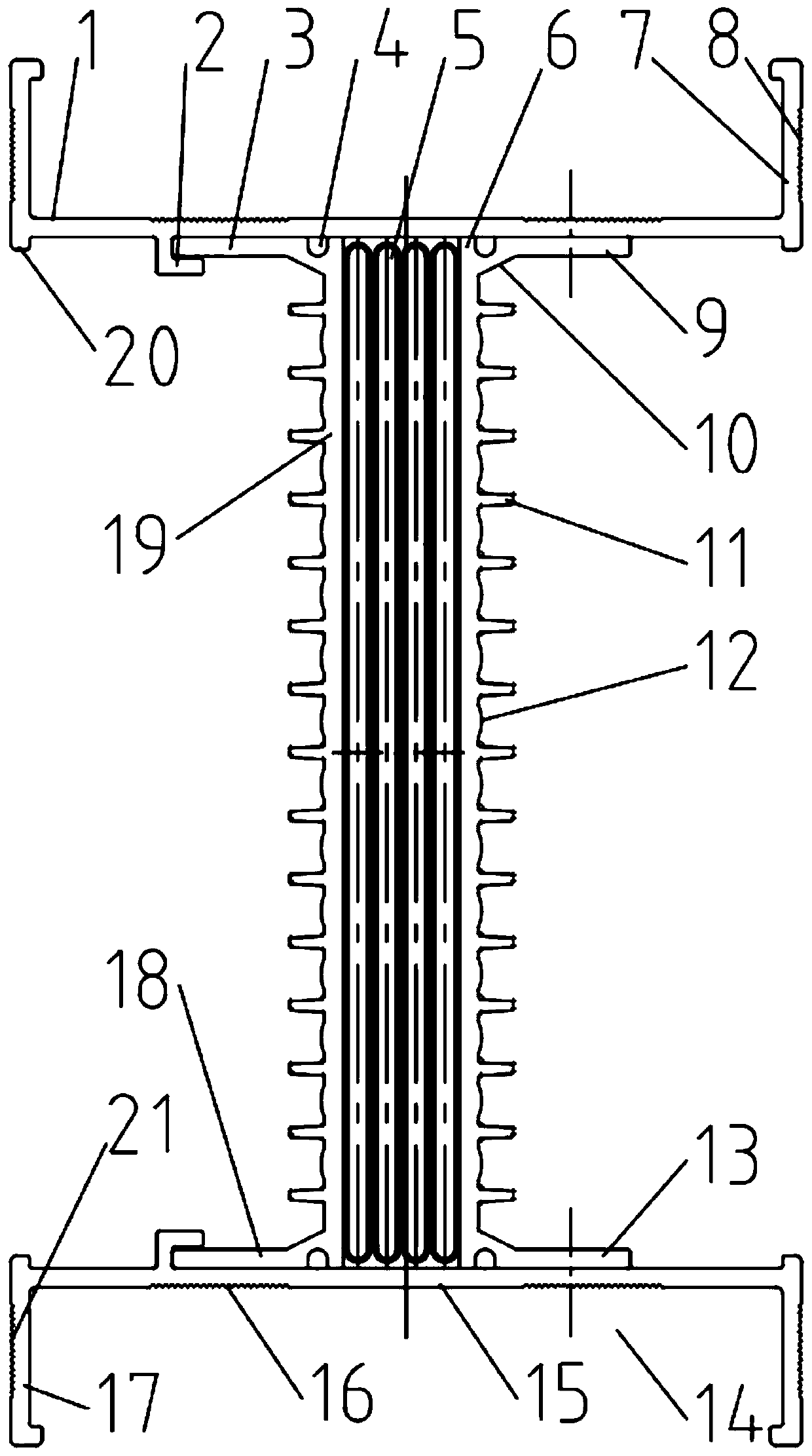

[0018] As shown in the figure, a lightweight dense insulated busway is further improved on the basis of the dense busway in the prior art, including a busbar housing, which includes an upper cover plate 1 and a lower cover plate 15, A left side plate 19 and a right side plate 6 are arranged in the space between the upper cover plate 1 and the lower cover plate 15, and the phase line is surrounded by the upper cover plate 1 and the lower cover plate 15 between the left side plate 19 and the right side plate 6 Conductor placement cavity, the phase line conductor set is tightly clamped in the phase line conductor placement cavity;

[0019] The cross sections of the left side plate 19 and the right side plate 6 are horizontal U-shaped structures facing away from each other. The positions corresponding to the edges are respectively provided with transverse limiting grooves 2, and the upper side 3 and the lower side 17 of the left side plate 19 are respectively limited and clamped o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com