Polymer slurry, composite diaphragm and preparation method thereof

A composite diaphragm and polymer technology, applied in the direction of structural parts, electrical components, battery pack parts, etc., can solve the problems of poor uniformity of the diaphragm, poor coating process, poor air permeability, etc., to save drying procedures, simplify the preparation process, and improve the effect of cell consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] According to some embodiments of the present invention, the preparation method of the ceramic slurry includes the following steps: firstly add a dispersant and a wetting agent to deionized water, and stir in a zigzag stirring disperser at a speed of 300~600 r / min 0.5 h to obtain a solution; the Al 2 o 3 Add the particles into the solution, first stir at 3000-4000 r / min for 3 h to obtain a ceramic dispersion; adjust the speed to 1500-2000 r / min, add binder and thickener, stir for 1 h, Finally, reduce the rotation speed to 100-200r / min to defoam, and filter to obtain ceramic slurry.

[0065] In the preparation process of the above-mentioned ceramic slurry, a dispersant and a wetting agent are firstly added for pre-dispersion; adding Al 2 o 3 After stirring at a high speed to generate a strong shear force, the aggregated large particles can be quickly dispersed into smaller particles to enhance the dispersion effect; after the ceramic particles are dispersed, the binder...

Embodiment approach

[0081] The invention also provides a preparation method of the polymer slurry. According to some embodiments of the present invention, the preparation method of the polymer slurry includes the following steps: firstly adding the polymer, the dispersant and the binder into the deionized water for stirring and mixing, shaking and dispersing to obtain the polymer pre-solution; Add a thickener to the polymer pre-solution, stir to dissolve, continue to add wetting agent A and wetting agent B, stir to disperse, and filter to obtain a polymer slurry.

[0082] (3) Composite diaphragm

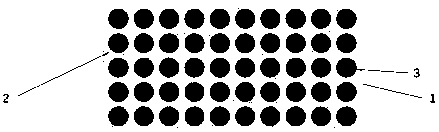

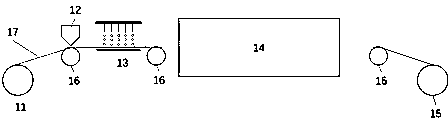

[0083] Another aspect of the present invention also provides a composite diaphragm, comprising a base film, a ceramic coating and a polymer dot coating respectively coated on both sides of the base film, such as figure 1 and figure 2 shown. The ceramic coating can endow the separator with good heat resistance, and the polymer dot coating can improve the bonding performance between the separator and ...

Embodiment 1

[0114] (1) Preparation of ceramic slurry: first add 0.2 parts of dispersant polyethylene glycol and 0.2 parts of wetting agent octadecyltrimethylammonium chloride to 100 parts of deionized water, and stir in a zigzag disperser at 500 r / min speed stirring for 0.5 h to obtain the solution; 25 parts of Al 2 o 3 The particles were added to the solution, and stirred at 4000 r / min for 3 h to obtain a ceramic dispersion; the speed was adjusted to 1500 r / min, and 0.5 parts of binder PVP (polyvinylpyrrolidone, brand K60) and 0.6 Thickener CMC (sodium carboxymethylcellulose), stirred for 1 h, and finally reduced the speed to 150 r / min to defoam, filtered to obtain ceramic slurry.

[0115] (2) Preparation of PVDF slurry: Mix 22 parts of PVDF powder with 100 parts of deionized water, 0.3 parts of BYK LP-C 22136 dispersant, 2 parts of PVP (polyvinylpyrrolidone, brand K60) binder, and use a high-speed oscillator Shake and disperse for 30 minutes to make a PVDF pre-dispersion, then add 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com