New energy waste heat generator suction end body casting process design method

A technology of casting process and design method, which is applied in the field of casting process design of the suction end body of the new energy waste heat generator, can solve the problems of large amount of calculation, harsh requirements, and tediousness, and achieve the optimization of the determination method, reduction of shrinkage porosity, and accuracy Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

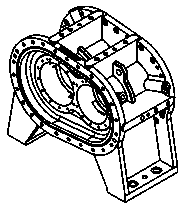

[0051] right figure 1 For the casting of the suction end body shown, the point model method is used to analyze the position of the hot joint, and it is compared with the position of the actual hot joint of the suction end body casting. The accuracy of the analysis and prediction of the hot joint is 88%. The method in the application is used to analyze the hot spots, and the accuracy rate of the hot spots prediction is 98%. It can be seen from the prediction accuracy rate that the application can accurately heat the heat section and reduce the occurrence probability of shrinkage porosity, shrinkage cavity, and porosity of the casting during the production process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com