A high-sensitivity temperature-compensated fiber grating acceleration sensor

An acceleration sensor and fiber grating technology, applied in the direction of acceleration measurement using inertial force, etc., can solve the problems of difficult to grasp the thermal expansion coefficient of diamond beam and vibration beam, no temperature compensation unit, easy to break fiber, etc., to solve the problem of temperature cross-sensitivity , the effect of suppressing longitudinal and vertical offset and improving the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

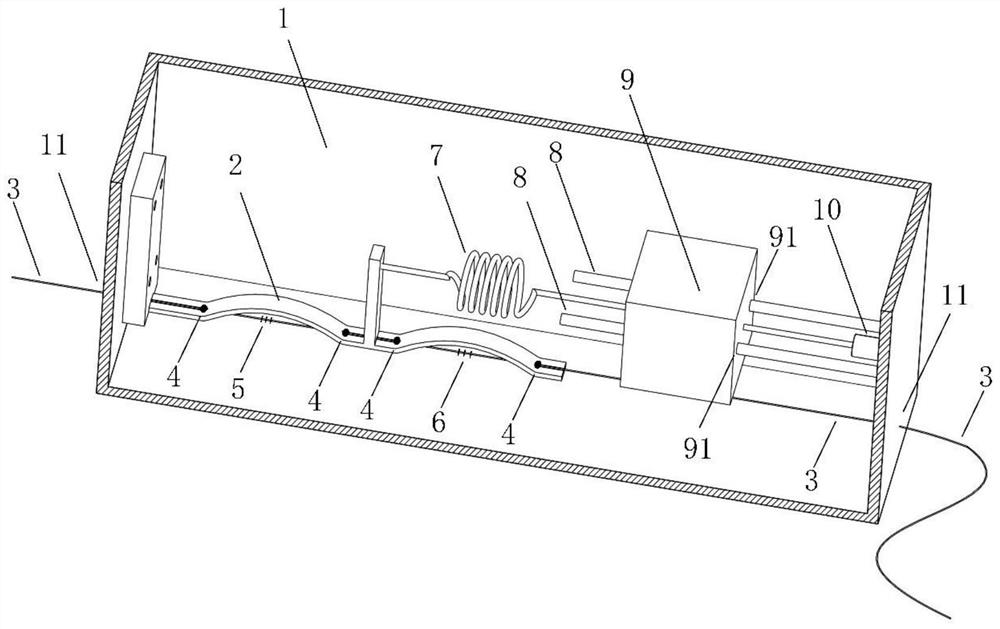

[0022] A high-sensitivity temperature-compensated fiber optic grating acceleration sensor of the present invention, as the cube-shaped housing 1 of the fiber grating acceleration sensor support structure, is made of rigid materials and is not easily deformed, and its left and right panels are provided with fiber outlets 11 , whose size depends on the package diameter of the fiber used. In particular, in order to better display the internal structure of the sensor, the upper panel and the front panel of the housing are not shown in the structure figure 1 This presentation is, in fact, a cube enclosed by complete six-sided panels.

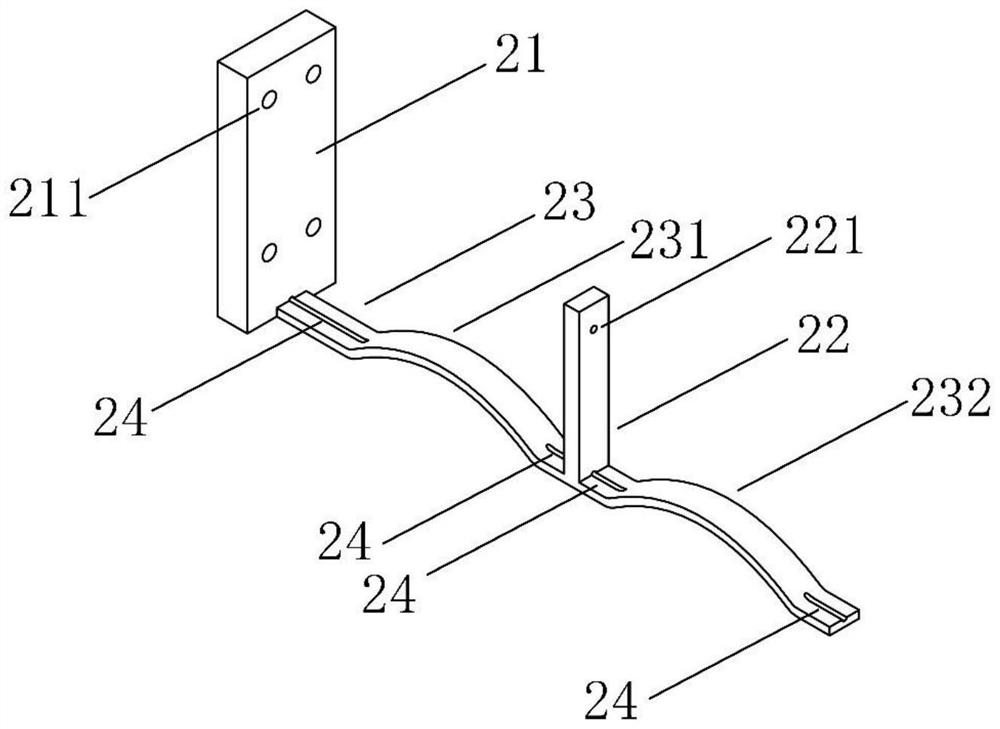

[0023] The double-arched elastic structural beam 2 used to convert the external acceleration information into the strain of the fiber grating is made of lightweight elastic metal, including a double-arched elastic beam base 21, with a first arch 231 of the beam, a second arch of the beam The double-arched elastic beam beam 23 of the two-arched shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com