Phased array imaging detection method for electrofusion welded joints of steel skeleton polyethylene composite pipes

A technology for welding joints and imaging detection, which is applied in the direction of measuring devices, processing detection response signals, instruments, etc., can solve the problem of difficult detection of resistance wires, and achieve the effect of improving the problem of detection blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

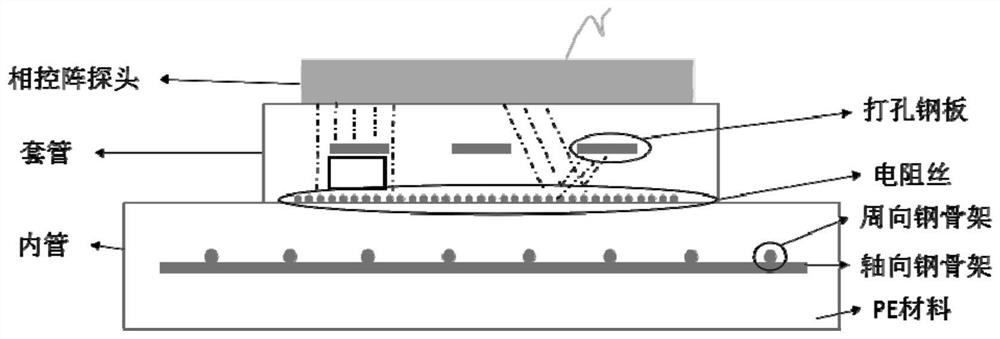

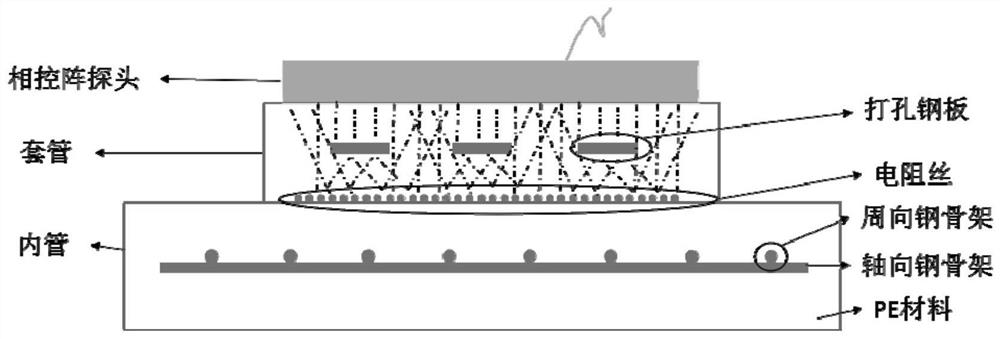

[0035] Obtain the electric fusion welding joint of the steel skeleton polyethylene composite pipe to be tested and the one-dimensional linear array phased array probe.

[0036]Debug the ultrasonic phased array detector 5. Specifically, set the detection parameters of the three line-scan channels according to the joints to be tested. Among them, the line-scan channel mode for 0° vertical detection can be adjusted according to the conventional PE pipe electrofusion welding joint line. Scan detection requires setting, and the other two channel modes are linear scan mode with preset angle and setting opposite to the deflection direction of the preset angle. It should be noted that the preset angle should not exceed 15°.

[0037] Apply ultrasonic coupling agent evenly on the outer detection surface of the electric fusion welding joint of the steel skeleton polyethylene composite pipe to be tested, place the phased array linear array probe 3 on the detection surface on which the coup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com