A phased array imaging detection device and method for a steel skeleton polyethylene composite pipe

A polyethylene composite pipe, imaging detection technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problems of inability to achieve non-destructive testing, large detection blind spots, complex structures, etc., and achieve fast and efficient online real-time imaging detection and improvement. The effect of detecting blind spot problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the present invention will be clearly and completely described below. Obviously, the described embodiments are only a part of the embodiments of the present invention. For those of ordinary skill in the art, they can be obtained without paying creative work. All other embodiments, all belong to the protection scope of the present invention. The ultrasonic phased array detector and the structure of the steel skeleton polyethylene composite pipe to be tested are existing.

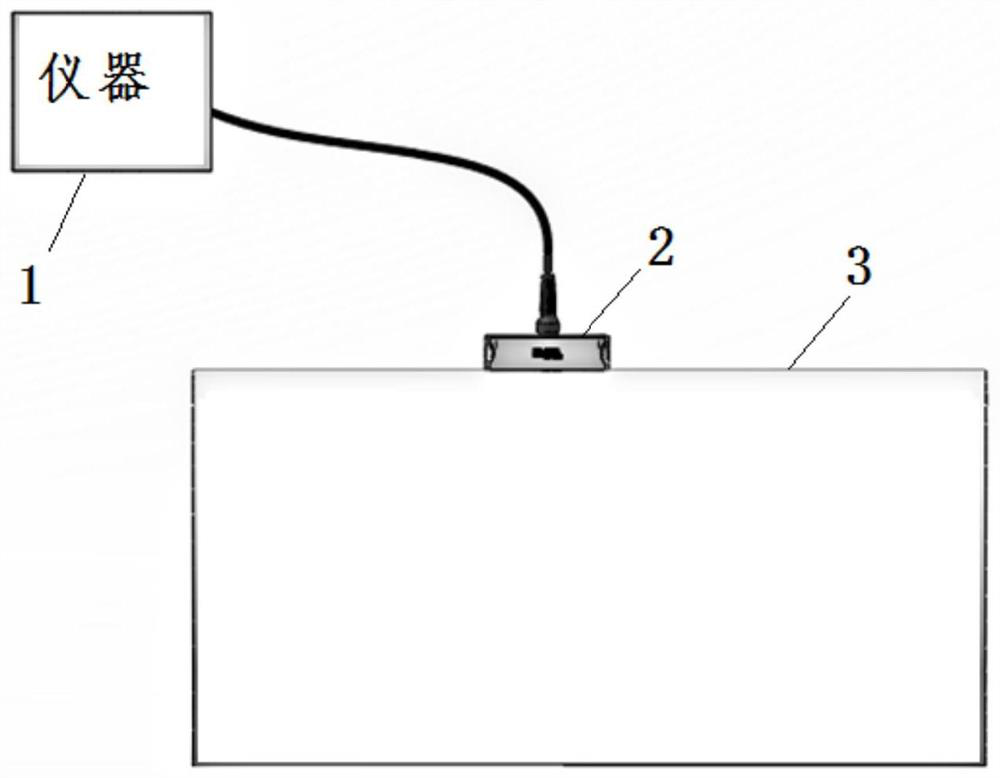

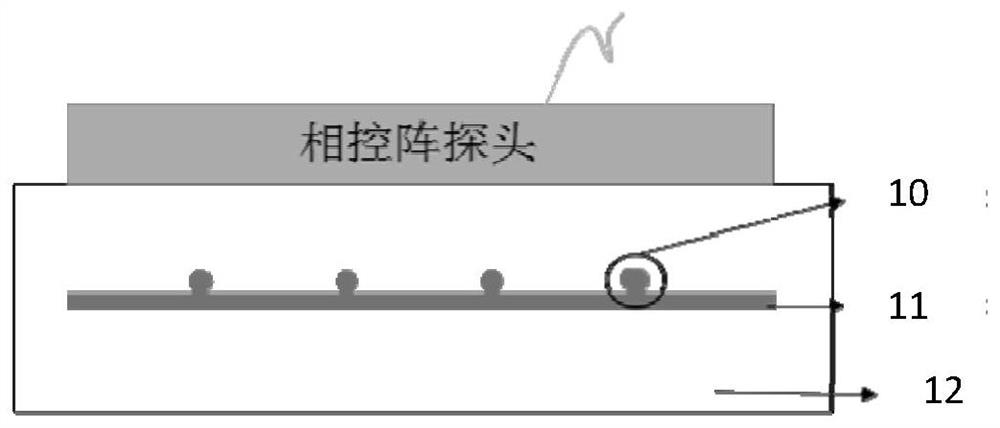

[0034] see figure 1 and Figure 7 , a phased array imaging detection device for a steel skeleton polyethylene composite pipe, mainly comprising an ultrasonic phased array detector 1 and a phased array linear array probe 2 for inspecting a steel skeleton polyethylene composite pipe, the phase The controlled-array linear array probe 2 is placed on the outer surface of the steel skeleton polyethylene composite pipe 3 to be tested, parallel to the axial direction of the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com