A portable ultrasonic guided-wave phased array bolt detection system

An ultrasonic guided wave and detection system technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc. problem, to achieve the effect of light weight, fast and efficient online real-time imaging detection, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only part of the embodiments of the present invention. All other obtained embodiments belong to the protection scope of the present invention. The ultrasonic guided wave phased array bolt detector and the bolt probe structure are existing.

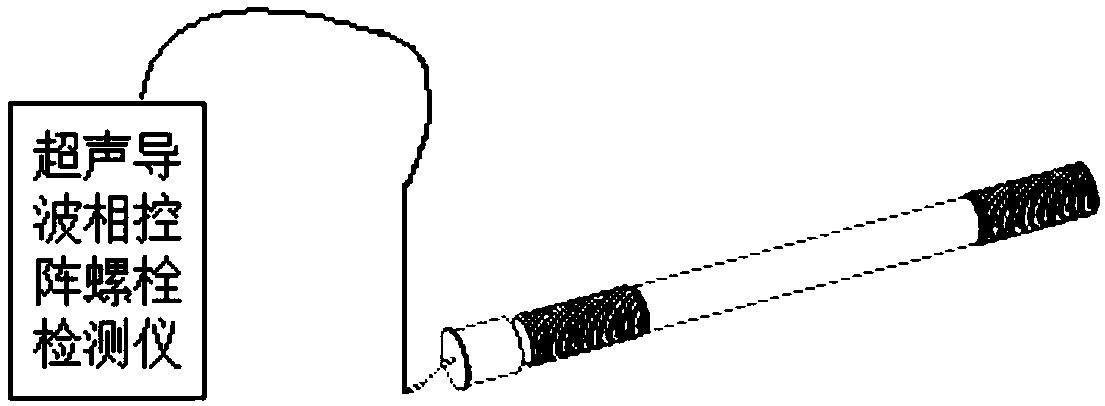

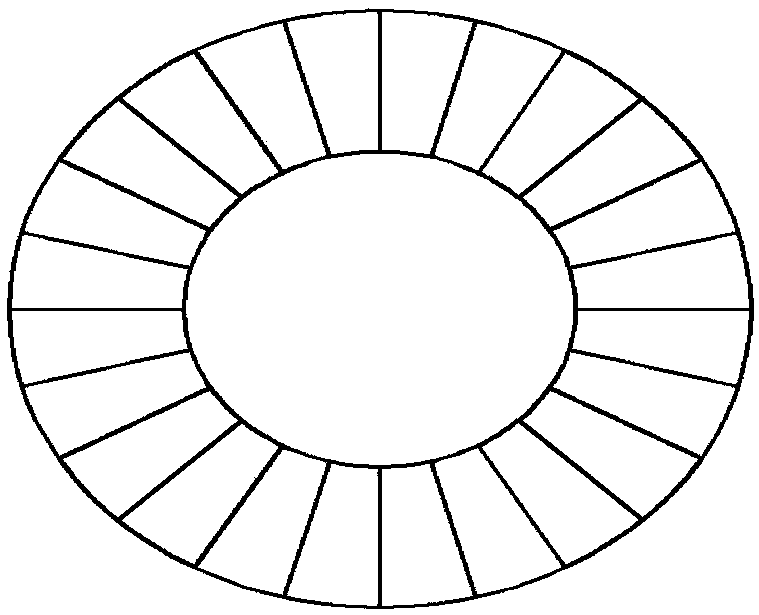

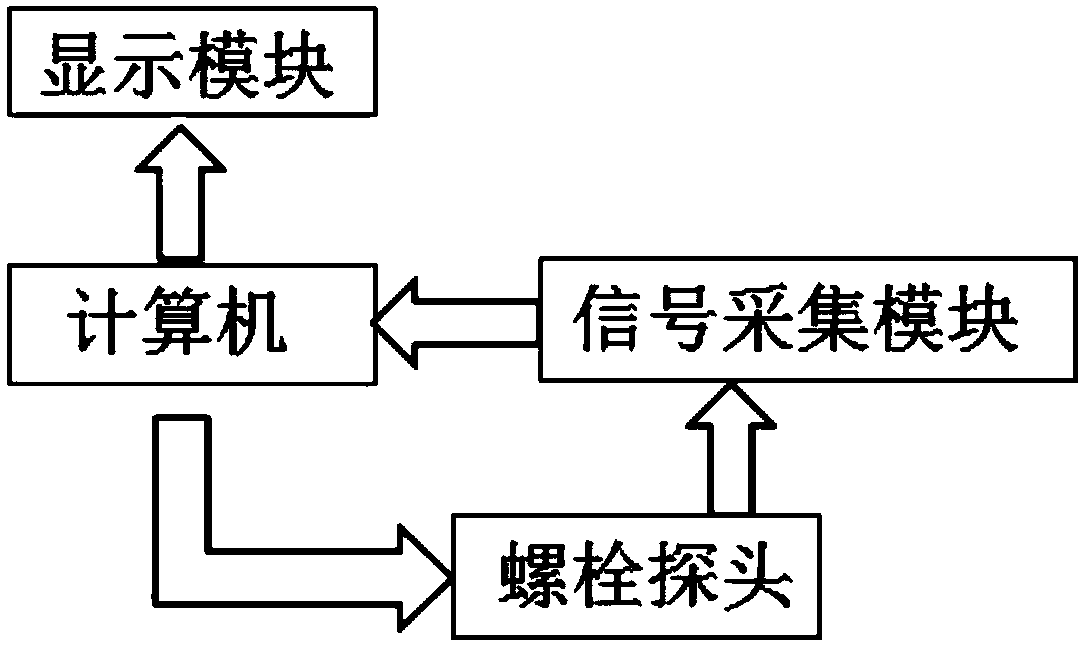

[0024] Such as figure 1 , figure 2 As shown, the present invention includes an ultrasonic guided wave phased array bolt detector and a bolt probe, and the bolt to be tested includes a screw rod and a bolt end, and is characterized in that: the ultrasonic guided wave bolt detector includes a computer, a signal acquisition module, and a display module ,Such as image 3 As shown, the bolt probe is placed at the end of the bolt of the bolt fastener to be tested and leads out a wire, which is connected to an ultrasonic guided wave bolt detector. The bolt probe is a one-dimension...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com