Detection system and detection method for nanoparticle chemical components

A nanoparticle and detection system technology, which is applied in the fields of nanoparticle analysis, particle and sedimentation analysis, and measuring devices, can solve the problems of too many measuring system equipment, complex operation and control, and inability to accurately obtain chemical composition, so as to ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

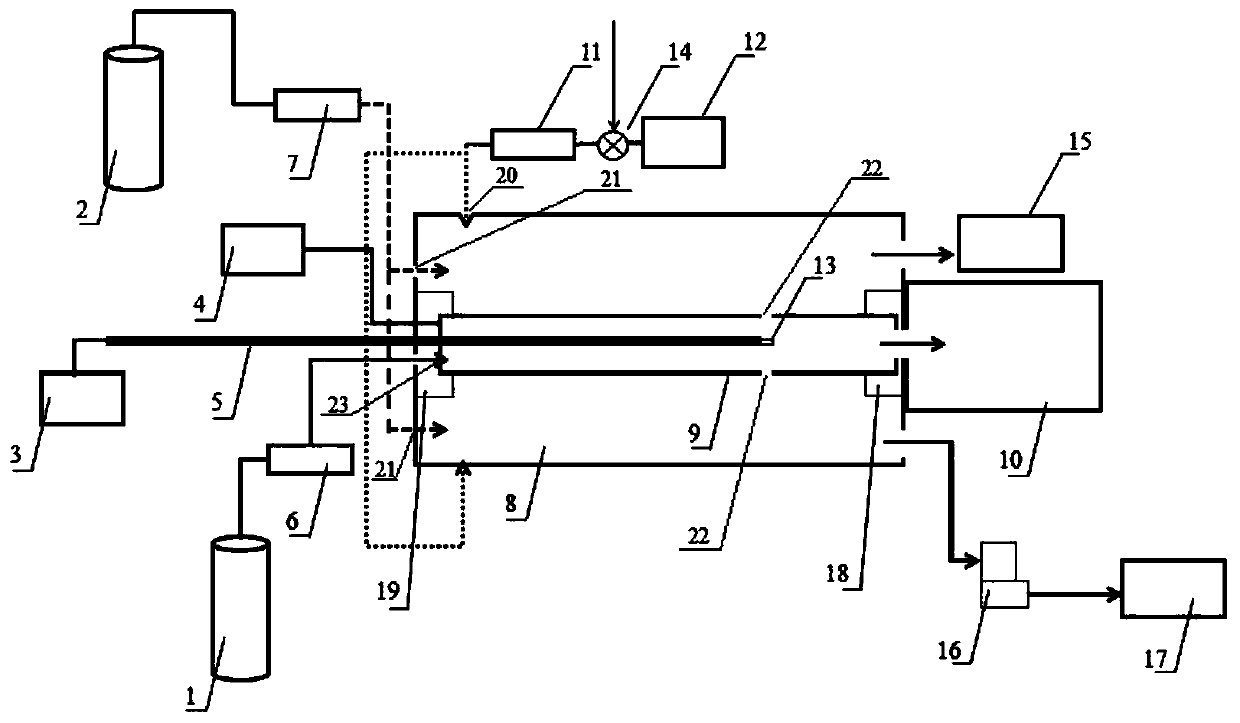

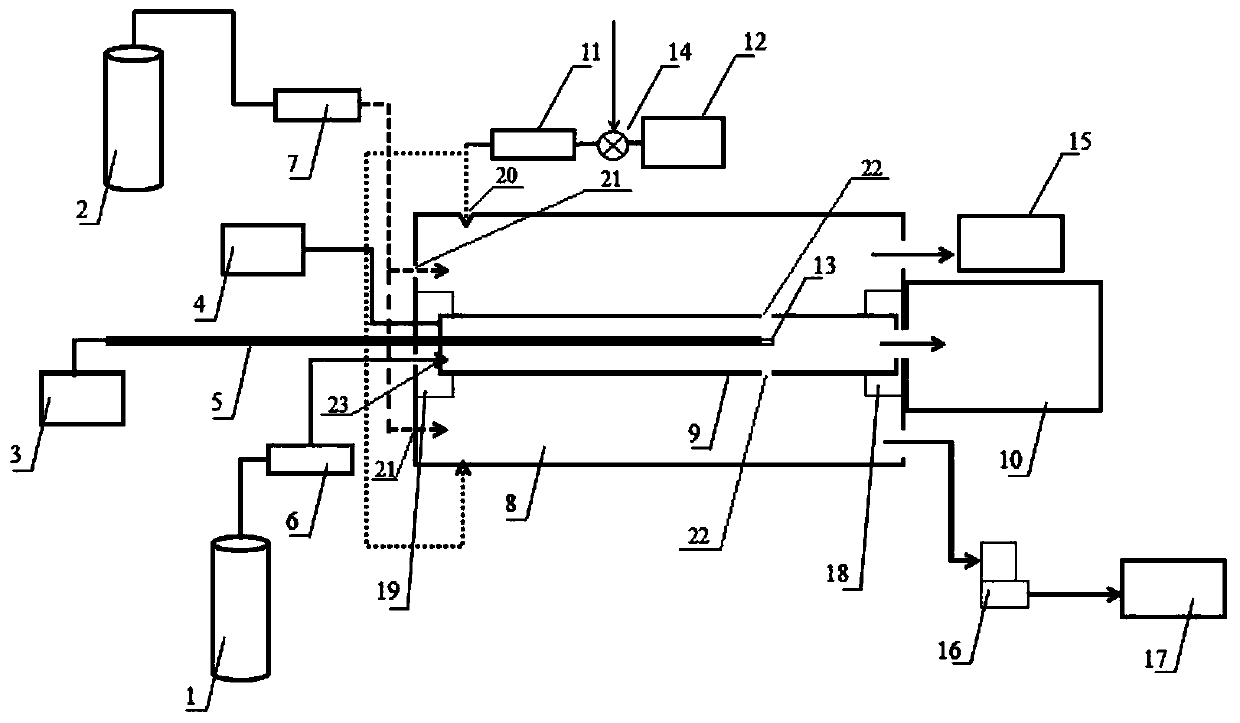

[0070] Turn on the first high-pressure gas source 1, the second high-pressure gas source 2, the first flow controller 6, and the second flow controller 7, and the gas enters the metal shell 9 as a protective gas to blow away the gas other than the particles that need to be collected. Enter the collection chamber 8 as sheath gas for separating single-size particles. Turn on the third flow controller 16 and the air pump 17 to control the air pressure in the collection chamber. Push the sampling rod 5 to a specific position, and the valve body 14 can be used to select to measure the external atmosphere or measure the known flow component particles generated by the particle generator 12 . The particles are charged by the charger 11 and enter the collection chamber. Turn on the voltage control power supply 4 to charge the metal shell, and at the same time, the first isolator 18 and the second isolator 19 ensure that it is not connected to the wall of the collection chamber and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com