Preparation device and preparation method of carbon quantum dots

A technology of carbon quantum dots and preparation devices, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problem of high cost of carbon quantum dots, and achieve the effects of saving time, cost and financial resources, wide application range, and simple devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

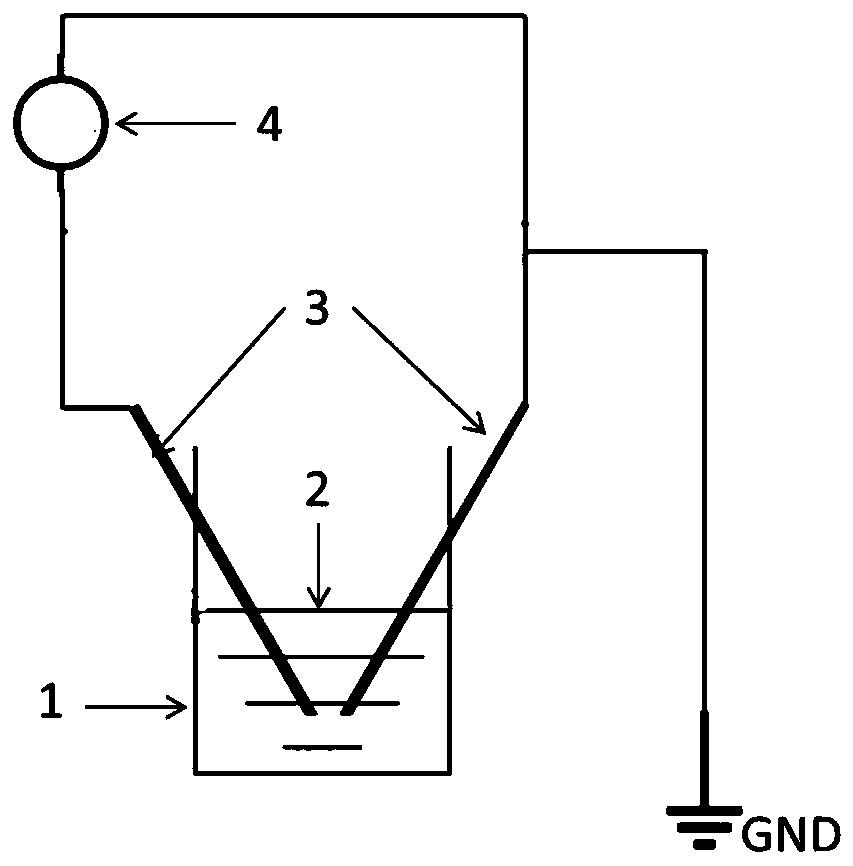

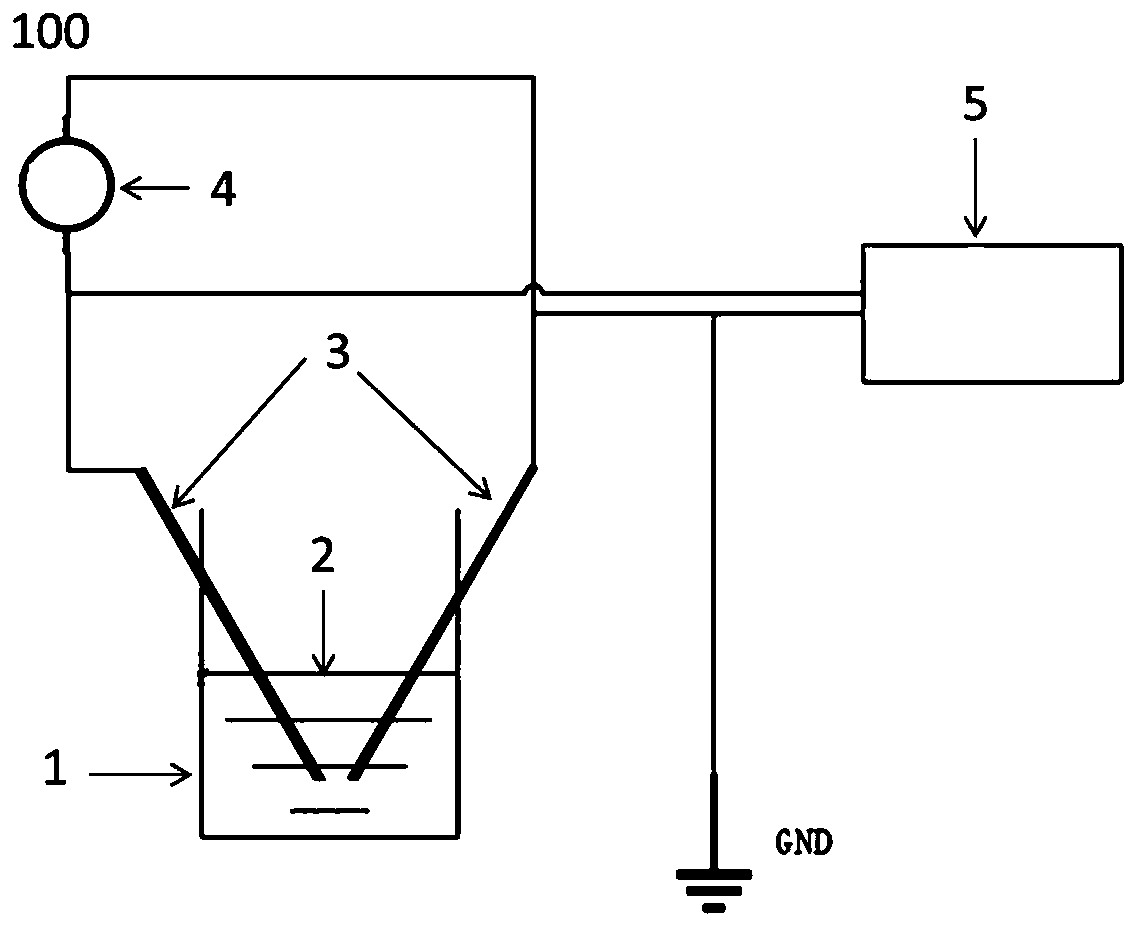

[0043] A preparation device 100 for carbon quantum dots, such as figure 1 As shown, it includes: discharge container 1, absolute ethanol 2, two conductive needles 3, and power supply 4;

[0044] The absolute ethanol is arranged in the discharge vessel;

[0045] The two conductive needles are respectively placed in the absolute ethanol, and one of the conductive needles is connected to the power supply, and the other conductive needle is externally grounded;

[0046] Wherein, when the power supply energizes the conductive needles, plasma is generated between the two conductive needles to break through the absolute ethanol and discharge.

[0047] For example, one end of each conductive needle is in contact with absolute ethanol, the other end of one conductive needle is connected to the high-voltage pole of the high-voltage AC power supply, and the other end of the other conductive needle is grounded. By adjusting the frequency and voltage amplitude of the AC power supply and ...

Embodiment 2

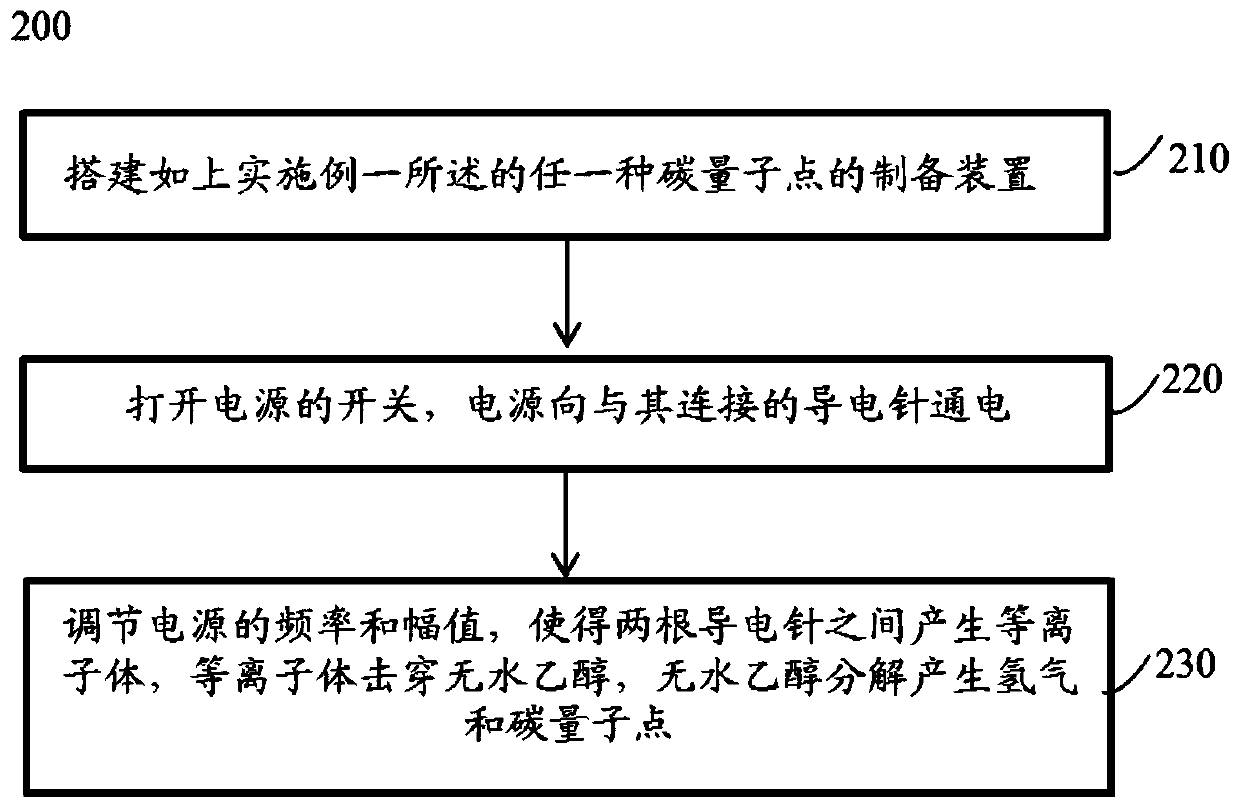

[0065] A carbon quantum dot preparation method 200 based on any preparation device described in Embodiment 1, such as image 3 and Figure 4 shown, including:

[0066] Step 210, constructing any carbon quantum dot preparation device as described in the first embodiment above;

[0067] Step 220, turn on the switch of the power supply, and the power supply energizes the conductive pin connected to it;

[0068] Step 230, adjusting the frequency and amplitude of the power supply, so that plasma is generated between the two conductive needles, the plasma breaks down the absolute ethanol, and the absolute ethanol decomposes to generate hydrogen and carbon quantum dots.

[0069] In this embodiment, from the perspective of green, economical and sustainable development, carbon quantum dots are prepared at the same time as ethanol reforming to produce hydrogen. The device is simple, the equipment requirements are low, and the construction and operation process is simple. Through the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com