Multi-pore cement concrete with photocatalytic purification effect

A cement concrete and multi-porous technology, which is applied in special compound water treatment, light water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of lack of purification ability, achieve simple operation, weaken the impact, and theoretically strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of porous cement concrete with photocatalytic purification effect, it comprises the following steps:

[0032] 1) For the porous cement concrete sample block, the aggregate should be single particle size or graded combination, the cement can be 42.5MPa Portland cement, the water-cement ratio should be 0.25, and the forming method is recommended to be obtained by vibratory compaction.

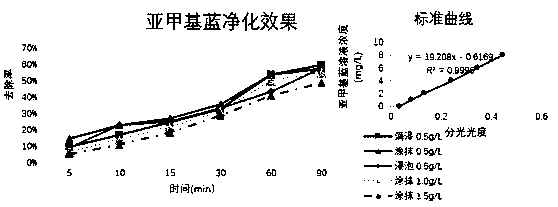

[0033] 2) Nano-titanium dioxide dispersion liquid P25 nano-titanium dioxide is dispersed in water to form a dispersion liquid with a concentration of 1.5g / L and 1.0g / L.

[0034] In fact, the nano-titanium dioxide dispersion is applied to the upper surface of the porous cement concrete.

[0035]Preferably, the porous cement concrete sample block is selected from any one or several of basalt, granite and quartzite.

[0036] Preferably, the particle size range of the porous cement concrete sample block is 4.75-9.50mm, and the specific surface area is 200-900m 2 / g.

[0037] Preferab...

Embodiment 2

[0047] A kind of porous cement concrete with photocatalytic purification effect, it comprises the following steps:

[0048] 1) The aggregate of the porous cement concrete sample block can be selected from a single particle size or a gradation combination. The cement is 52.5MPa Portland cement, the water-cement ratio is recommended to be 0.32, and the molding method is the vibration compaction method.

[0049] 2) The nano-titanium dioxide dispersion liquid is dispersed in water with P25 nano-titanium dioxide at a concentration of 0.5 g / L.

[0050] In fact, the nano-titanium dioxide dispersion is applied to the upper surface of the porous cement concrete.

[0051] Preferably, the porous cement concrete sample block is selected from any one or several of basalt, granite and quartzite.

[0052] Preferably, the particle size of the porous cement concrete sample block is 4.75-9.50mm, and the specific surface area is 200-900m 2 / g.

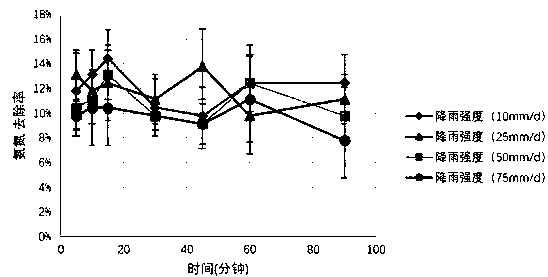

[0053] Preferably, the stormwater runoff pollut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com