Method and device for determining minimum miscibility pressure of oil and gas

A technology of miscible pressure and determination method, applied in measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of poor calculation stability, large difference in initial value, and change of minimum miscible pressure of oil and gas, and achieves strong theory and improved accuracy. , the effect of improving convergence and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

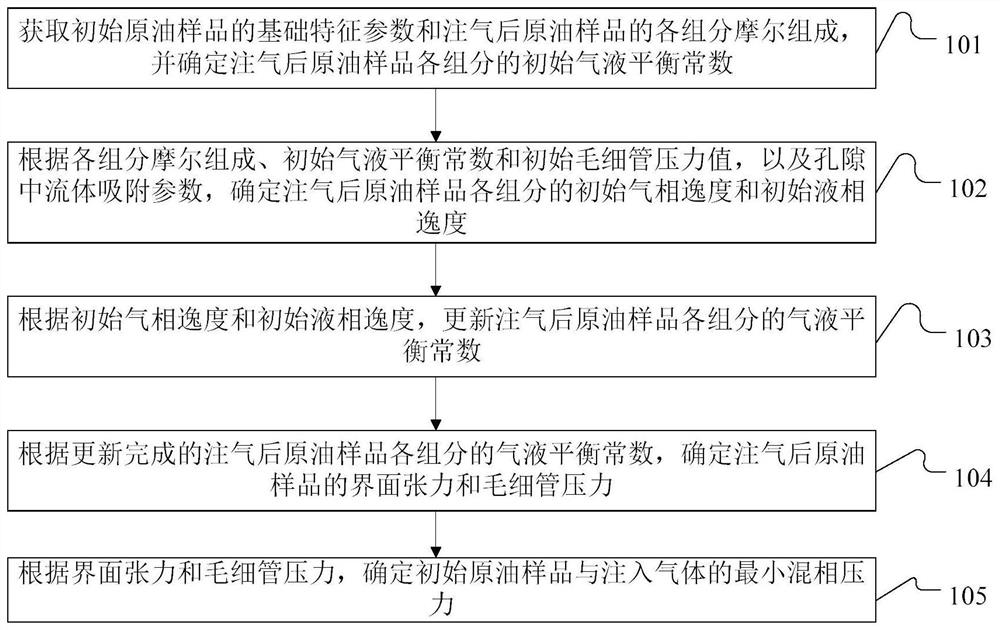

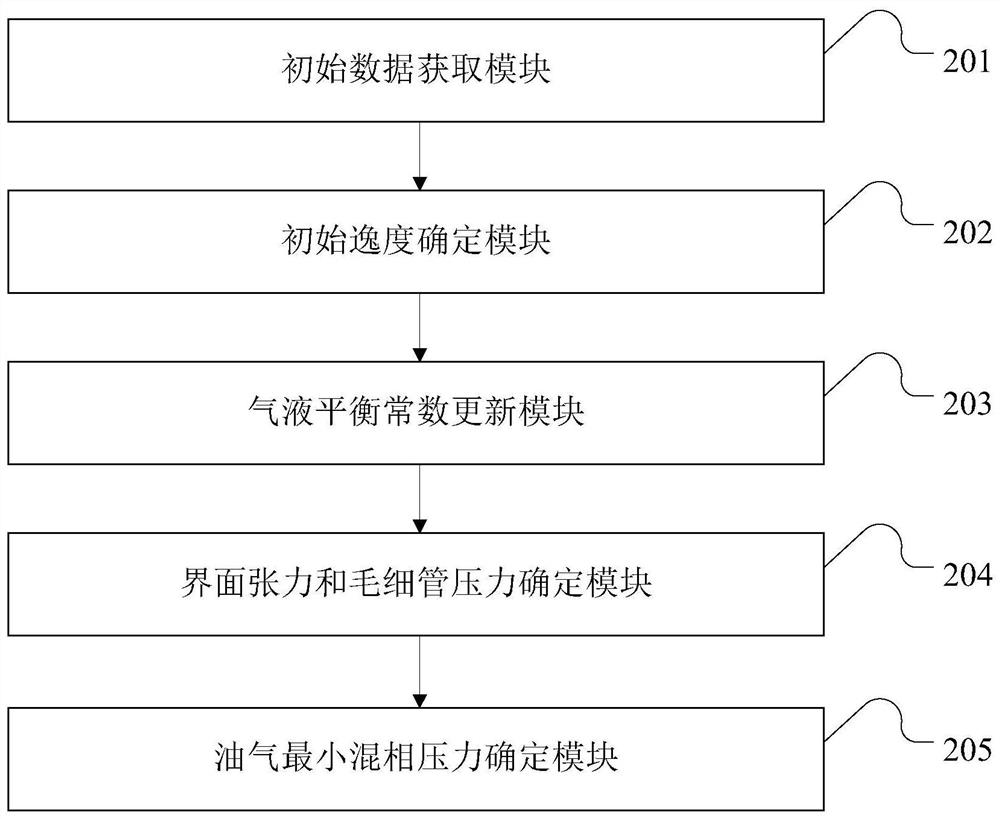

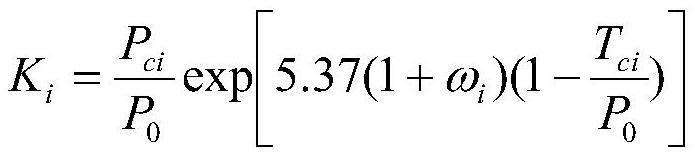

Method used

Image

Examples

Embodiment 1

[0101] Step a, determine the basic characteristic parameter value, as follows:

[0102] A simulated oil system, temperature T = 344K, injected gas is CO 2 and CH 4 Mix gas in equal proportions, set the pore radius R p = 1 μm.

[0103] The simulated oil components and their properties are shown in Table 1:

[0104] Table 1 Crude oil components and component properties

[0105] components z i

T c / K

P c / MPa

ω MW x i

CO 2

0 304.21 7.384 0.2250 44.010 82.00 CH 4

0.25 190.58 4.604 0.0104 16.043 74.05 n-C 4 h 10

0.50 425.18 3.797 0.2010 58.123 193.90 n-C 10 h 22

0.25 617.65 2.115 0.4900 142.290 440.69

[0106] The interaction coefficients among the components are shown in Table 2:

[0107] Table 2 Interaction coefficients of crude oil components

[0108] components CO 2

CH 4

n-C 4 h 10

n-C 10 h 22

CO 2

0.0000 0.1000 0.1257 ...

Embodiment 2

[0119] Step a, according to the actual situation of the target reservoir, determine each parameter value, as follows:

[0120] In a shale reservoir, the temperature T=388.7K, and the pore radius is mostly about 50nm, set R p = 50nm.

[0121] Crude oil components and component properties are shown in Table 5:

[0122] Table 5 Crude oil components and component properties

[0123] components z i

P c / MPa

T c / K

MW Ω x i

CO 2

0.0 72.80 304.20 44.01 0.2250 78.0 CH 4

0.2506 45.40 190.60 16.04 0.0080 77.0 C 2 -C 4

0.22 42.54 363.30 42.82 0.1432 145.2 C 5 -C 7

0.20 33.76 511.56 83.74 0.2474 250.0 C 8 -C 9

0.13 30.91 579.34 105.91 0.2861 306.0 C 10+

0.1994 21.58 788.74 200.00 0.6869 686.3

[0124] The interaction coefficients among the components are shown in Table 6:

[0125] Table 6 Interaction coefficients between components of crude oil

[0126]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com