Nickel composite hydroxide particle and production method therefor, positive electrode active material for secondary battery and production method therefor, and secondary battery

A cathode active material, composite oxide technology, applied in the field of high-capacity and high-safety non-aqueous electrolyte secondary batteries, can solve problems such as the inability to increase current density, achieve excellent cycle characteristics, improve cycle characteristics, suppress gas effect that occurs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0224] By implementing the method of the present invention, that is, a series of steps of producing a nickel oxide with a predetermined composition, a step of producing a fired powder with a predetermined composition, and a step of washing the obtained fired powder with water and then drying the obtained fired powder, each product is manufactured. A lithium-nickel composite oxide in which the metal component reaches a specified molar ratio.

[0225] And, the specific surface area of the obtained lithium-nickel composite oxide was determined.

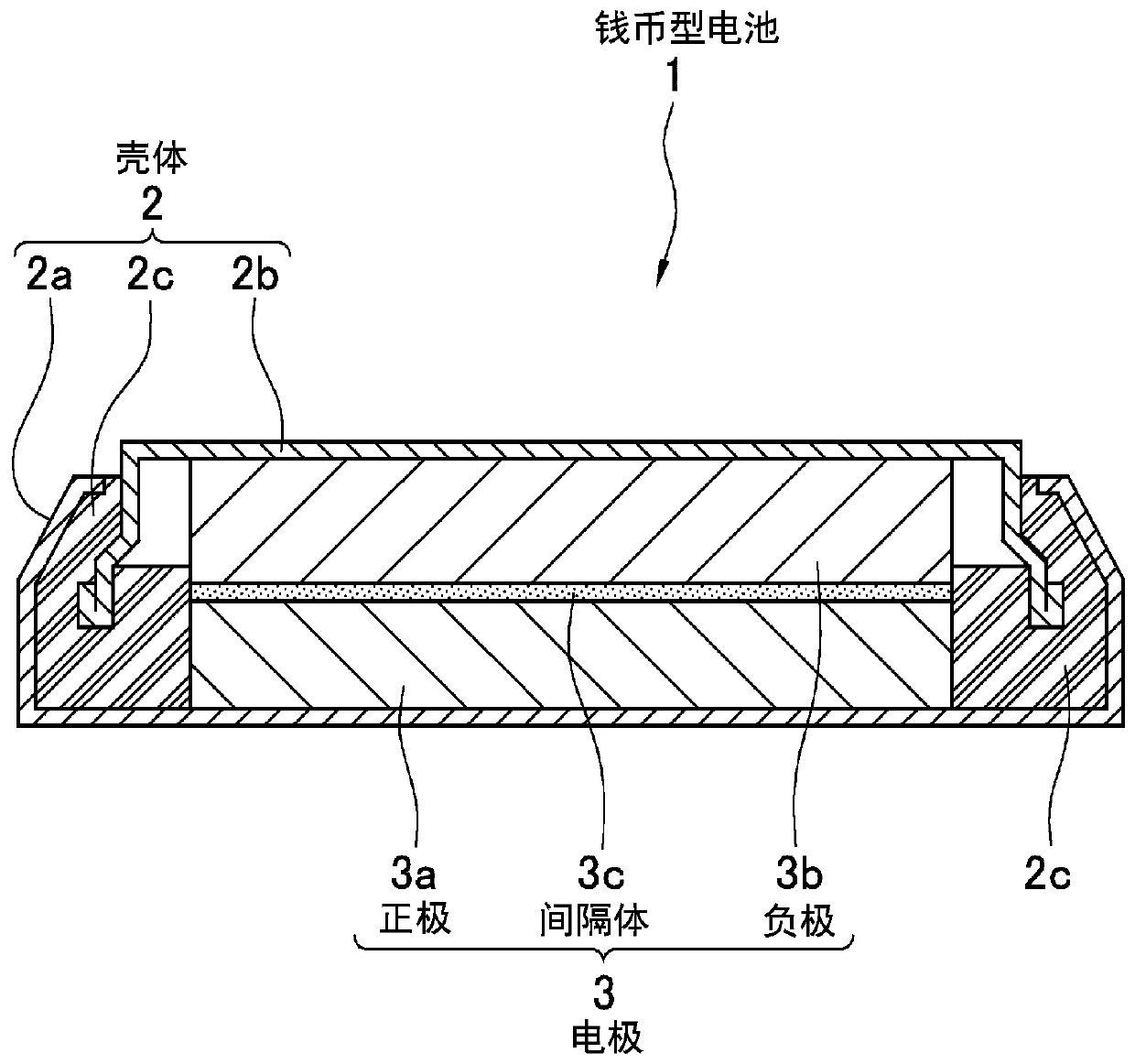

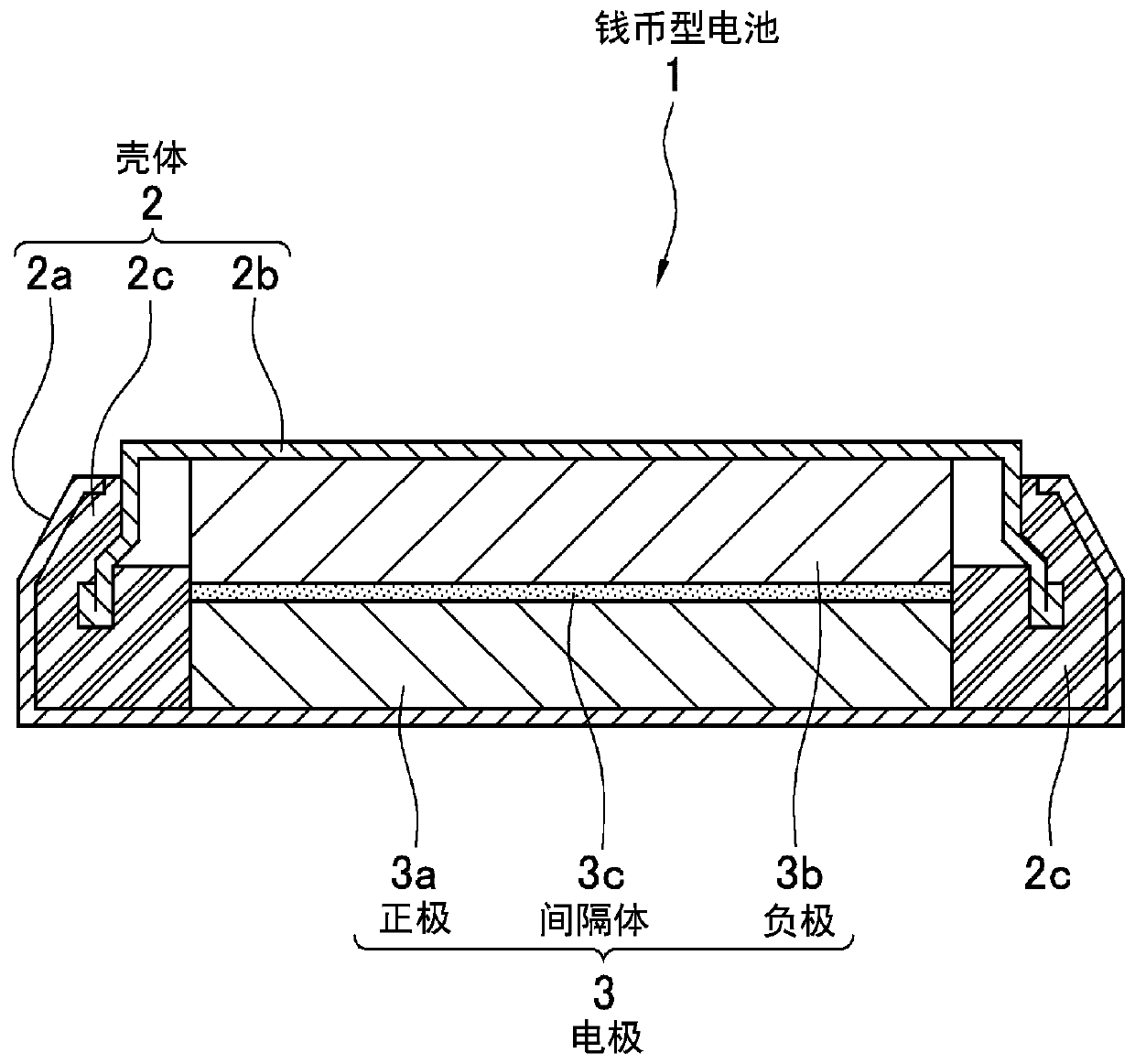

[0226] Then, the obtained lithium-nickel composite oxide was used as a positive electrode active material by the method described above to form a positive electrode material, and a coin-type battery was fabricated using the positive electrode material.

[0227] In addition, each raw material used in the manufacture of lithium-nickel composite oxide is such that the molar ratio of each metal component in the lithium-nickel composite oxi...

Embodiment 2

[0237] Except setting the slurry concentration of the process of washing the calcined powder with water to 500 g / L, and washing with water after stirring for 20 minutes, the operation was carried out in the same manner as in Example 1 to produce a lithium-nickel composite oxide, and the obtained powder was measured. The composition and specific surface area, as well as the initial discharge capacity, positive electrode reaction resistance, cycle retention rate and DSC calorific value of the coin-type battery fabricated using the powder. The results are shown in Table 1, respectively.

Embodiment 3

[0239] A lithium-nickel composite oxide was produced in the same manner as in Example 1, except that the slurry concentration in the step of washing the calcined powder with water was 1500 g / L, and washing was performed after stirring for 60 minutes. The composition and specific surface area of the obtained powder, and the initial discharge capacity, positive electrode reaction resistance, cycle retention, and DSC calorific value of coin-type batteries produced using the powder were measured. The results are shown in Table 1, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com