Polyvinylidene fluoride film with biomimetic three-period minimal surface structure and its preparation and application

A technology of polyvinylidene fluoride and extremely small curved surface, which is applied in the direction of structural parts, separators/films/diaphragms/spacer elements, non-aqueous electrolyte batteries, etc. Complicated problems, to achieve good mechanical properties, save costs, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

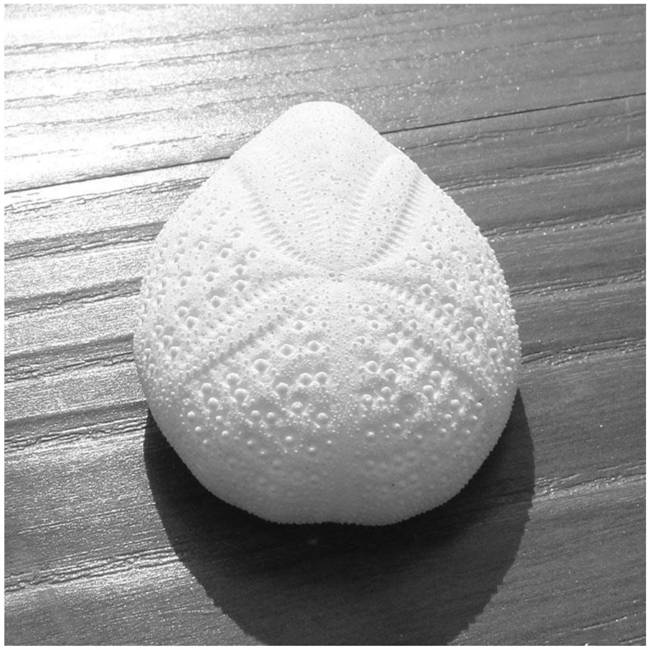

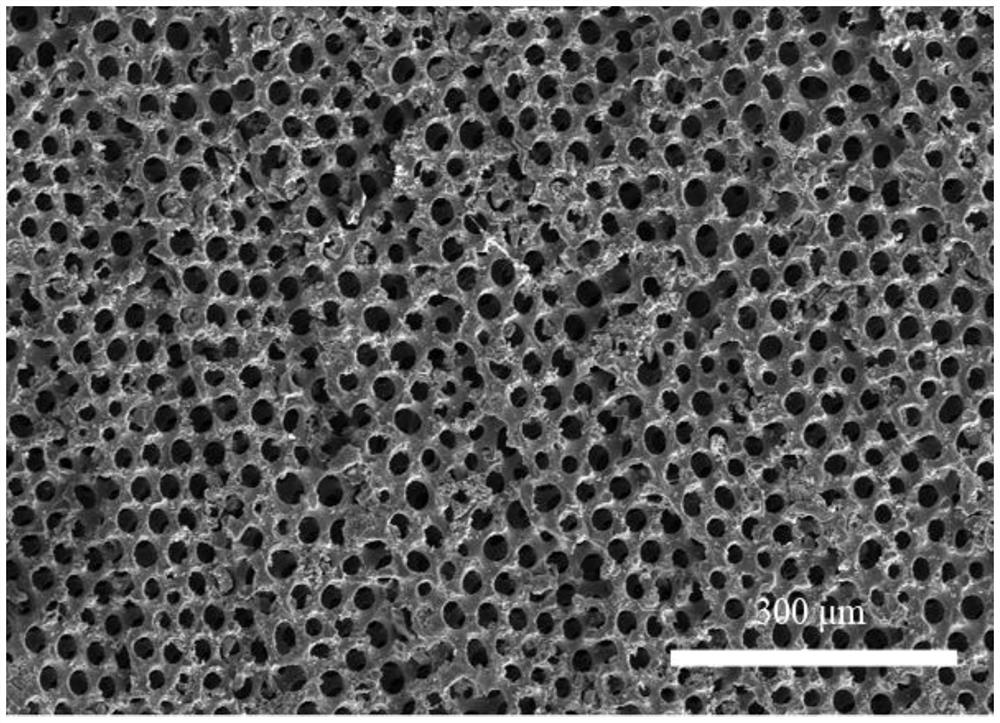

[0034]Choose relatively flat discarded white sea urchin shells and wash them with plenty of water to remove residual protein and other organic components on the surface. Break up the cleaned sea urchin shells, try to make the relatively flat part have the largest surface area; first use sandpaper with a particle size of 400 to polish the sea urchin shells until both sides are flat, and then use sandpaper with a particle size of 600 to clean the white sea urchin shells. Sand paper to close to 100 μm, and then continue to sand with 1000-grit sandpaper until it reaches a translucent state (about 100 μm), then ultrasonically wash it in water for 1 hour, then ultrasonically wash it in ethanol for 0.5 hour, and place it in an oven at 80°C Drying was carried out to obtain almost transparent sea urchin shell flakes with a thickness of about 100 μm.

[0035] Put the dried sea urchin shell slices flat on a watch glass, and then dissolve PVDF in NMP at a mass ratio of 1:10, and stir cont...

Embodiment 2

[0039] Choose relatively flat discarded white sea urchin shells and wash them with plenty of water to remove residual protein and other organic components on the surface. Break up the washed sea urchin shells, try to make the relatively flat part have the largest surface area; first use sandpaper with a particle size of 600 to polish the sea urchin shells until both sides are flat, and then use sandpaper with a particle size of 800 Sandpaper was polished to close to 110 μm, and then continued to polish the translucent state (110 μm) with sandpaper with a particle size of 1200, and then ultrasonically washed in water for 2 hours, and then ultrasonically washed in ethanol for 1 hour, and dried in an oven at 60°C to obtain almost Transparent flakes of sea urchin shells about 110 μm thick.

[0040] Put the dried sea urchin shell slices flat on a watch glass, and then dissolve PVDF in NMP at a mass ratio of 1:15, and stir continuously at 55°C to completely dissolve PVDF in NMP with...

Embodiment 3

[0044] Choose relatively flat discarded white sea urchin shells and wash them with plenty of water to remove residual protein and other organic components on the surface. Break up the cleaned sea urchin shells, try to make the relatively flat part have the largest surface area; first use sandpaper with a particle size of 400 to polish the sea urchin shells until both sides are flat, and then use sandpaper with a particle size of 600 to clean the white sea urchin shells. Sand paper to close to 160 μm, and then continue to sand with 1000-grit sandpaper to a translucent state (about 160 μm), then ultrasonically wash it in water for 1 hour, then ultrasonically wash it in ethanol for 0.5 hour, and place it in an oven at 80°C Drying was carried out to obtain almost transparent sea urchin shell flakes with a thickness of about 160 μm.

[0045] Place the dried sea urchin shell slices flat on a watch glass, and then dissolve PVDF in NMP at a mass ratio of 1:5, and stir continuously at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com