Etching groove for improving appearance yield of double-sided PERC battery and reducing acid consumption

A technology for etching grooves and batteries, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve problems such as poor appearance, and achieve the effects of solving abnormal appearance on the back, low acid concentration, and reducing acid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

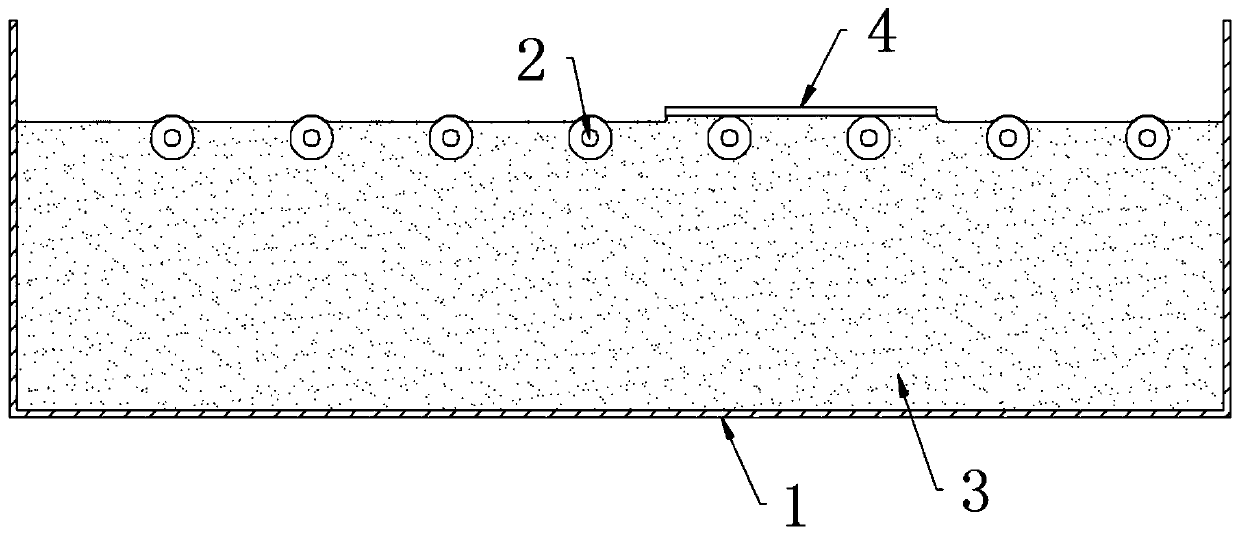

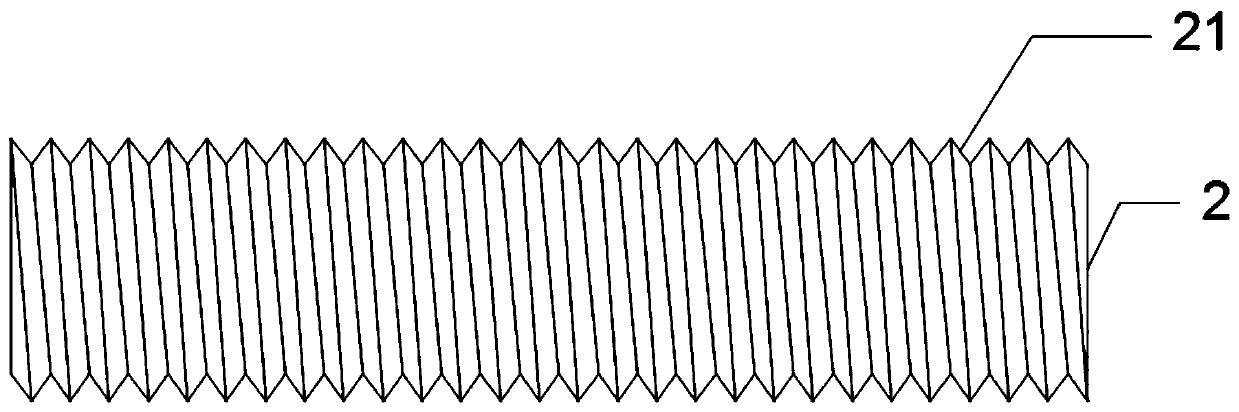

[0023] An etching tank for improving the appearance yield of a double-sided PERC battery and reducing acid consumption provided by a preferred embodiment of the present invention includes an etching tank main body, and an etching solution 3 is provided in the etching tank main body. The main body of the etching tank is built with several rollers 2 for driving the etching solution 3. The etching solution 3 does not completely submerge the rollers 2. The rollers 2 are provided with threads, and the thread depth of the threads ranges from 0.2 mm to 2 mm. , the thread pitch of the thread ranges from 0.2 mm to 3 mm.

[0024] The working principle of this embodiment: when the program is working, the motor provides power to drive the roller 2 to rotate. The thread depth of the thread provided on the roller 2 ranges from 0.2mm to 2mm, and the thread pitch of the thread ranges from 0.2mm to 3mm. The rotation of the roller brings acid and capillary action, and the silicon chip 4 is basi...

Embodiment 2

[0027] The preferred embodiment of the present invention makes the following optimizations on the basis of the first embodiment, the height of the exposed part of the roller 2 above the liquid level of the etching solution 3 ranges from 0.1 mm to 3 mm.

Embodiment 3

[0029] The preferred embodiment of the present invention makes the following optimizations on the basis of the first embodiment, the distance between the two adjacent rollers 2 ranges from 10m to 100mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thread depth | aaaaa | aaaaa |

| Thread pitch | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com