Test device and method for measuring void ratio of stone chippings test sample and controlling void ratio of stone chippings test sample

A test device and porosity technology, which is applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of uncontrollable stone chip porosity, poor operation convenience, small test range, etc., to achieve Accurate and reliable measurement results, convenient operation and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

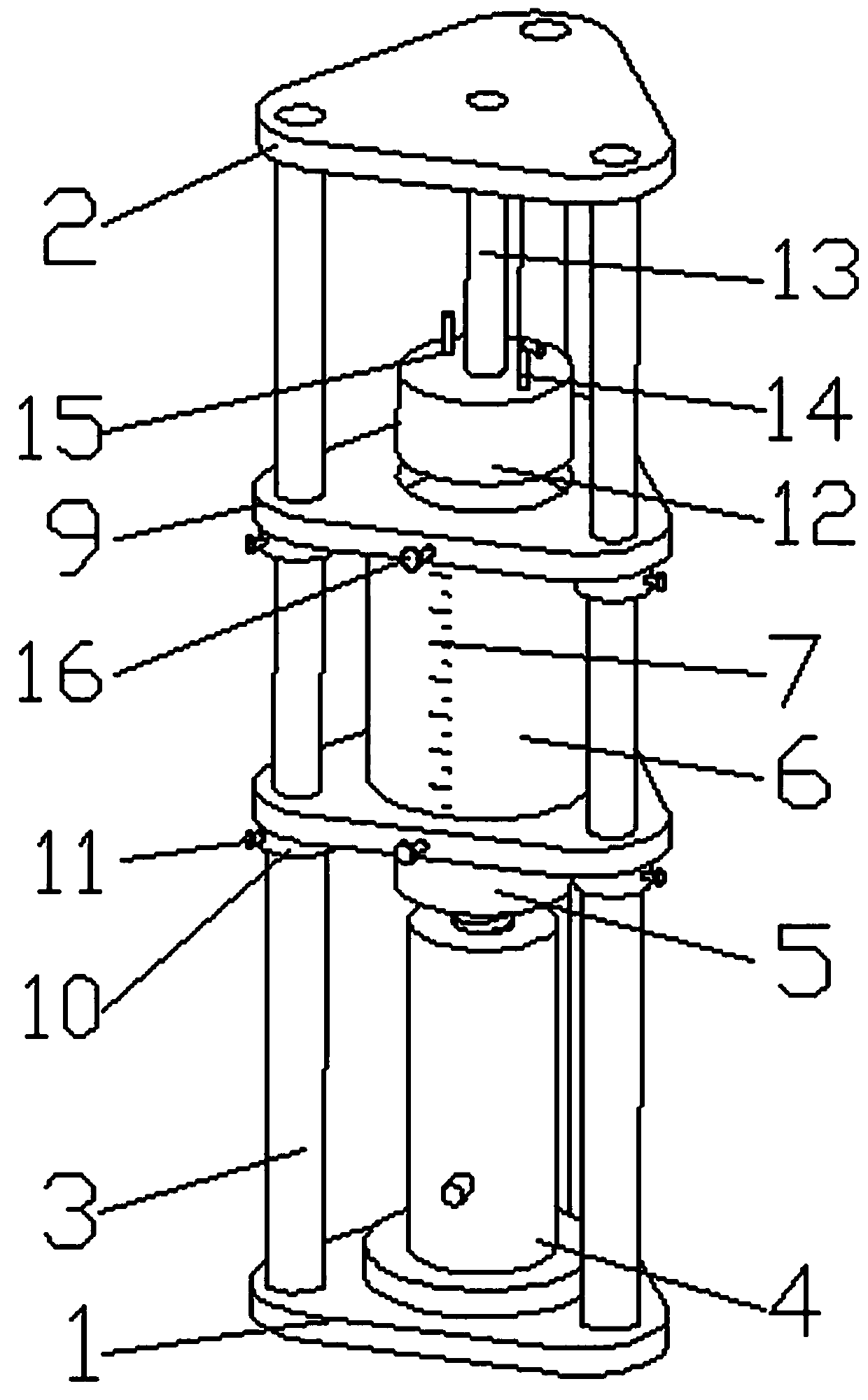

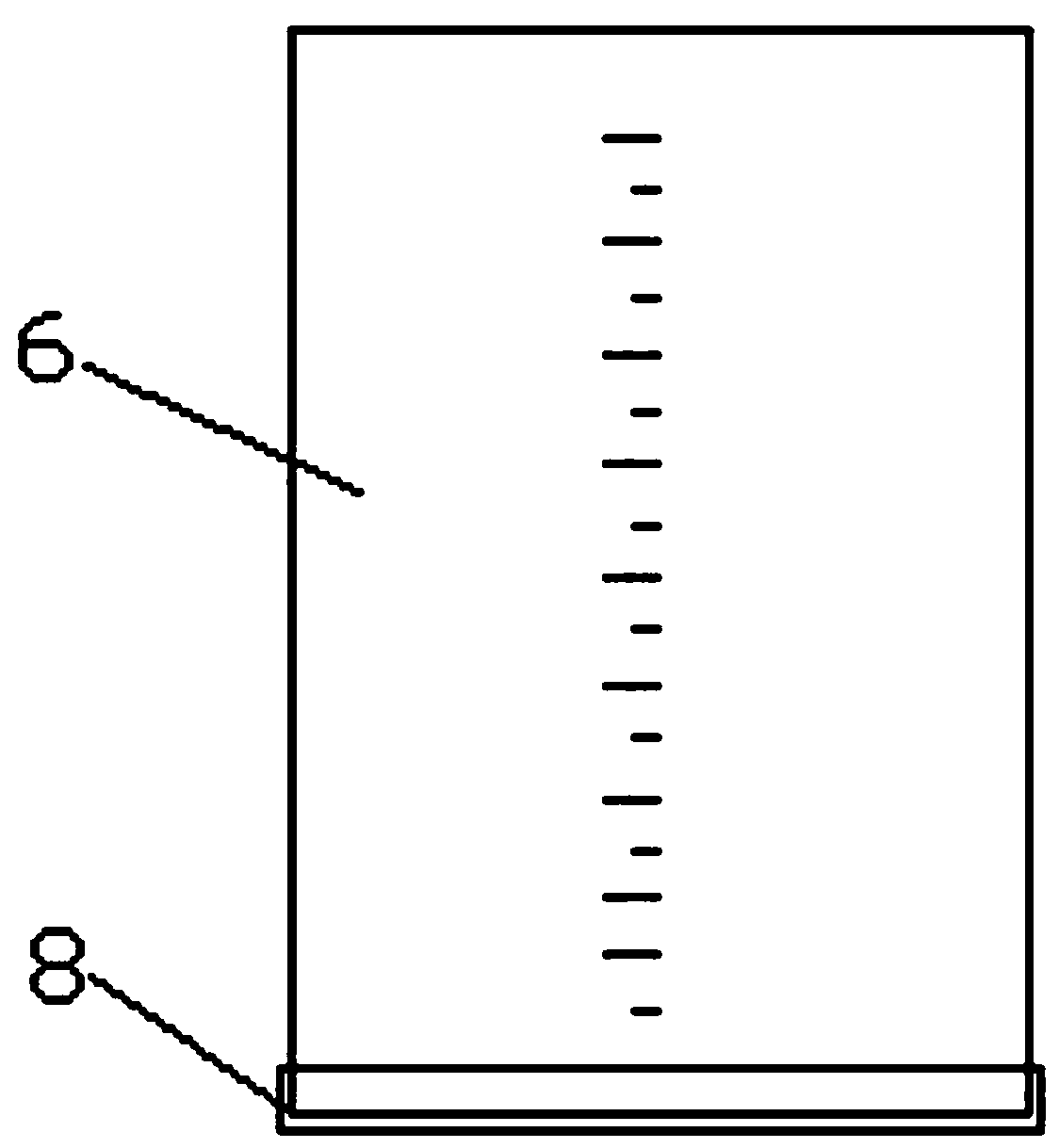

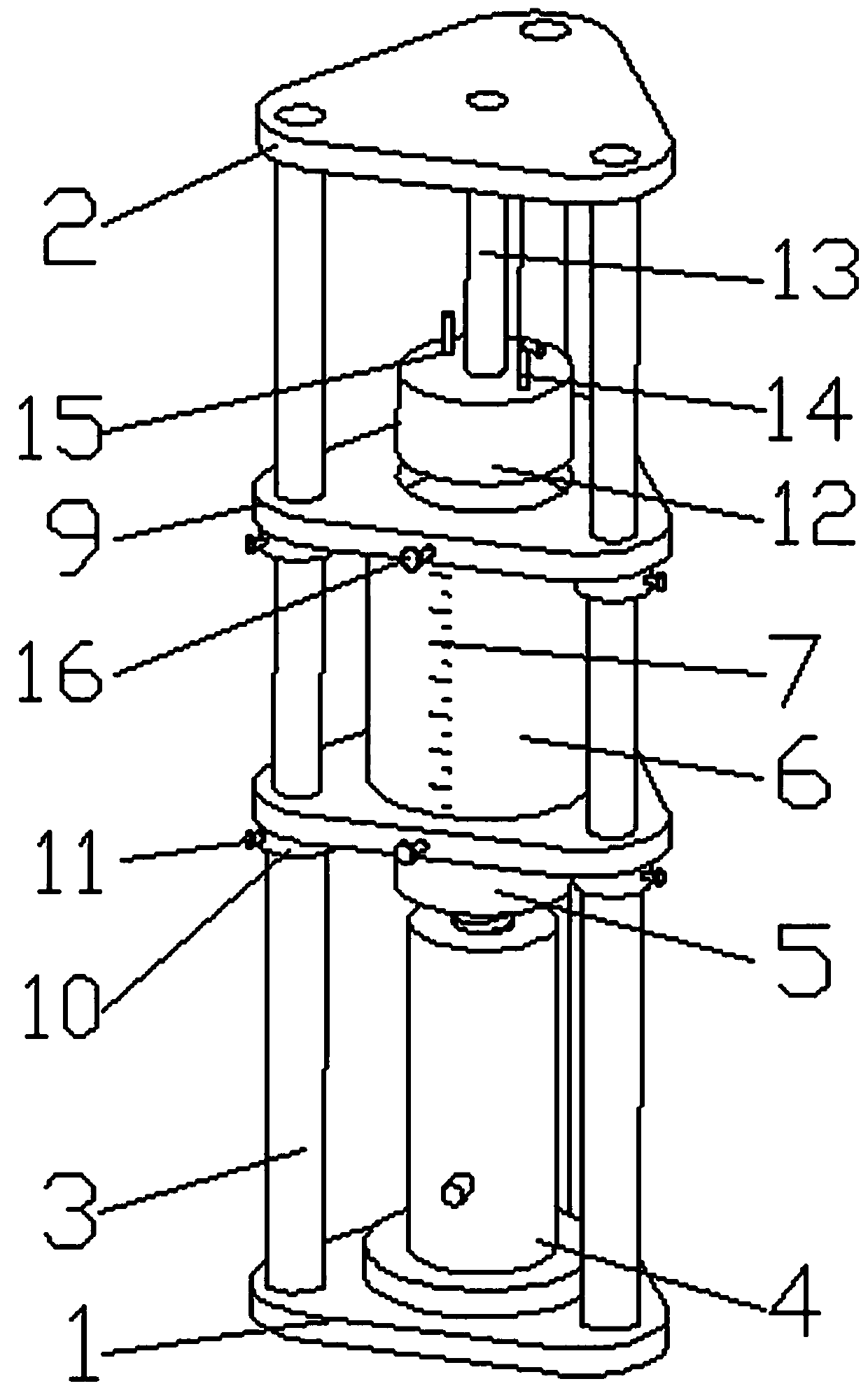

[0053] Such as figure 1 with figure 2 As shown, a test device for measuring the porosity of stone chip samples and controlling the porosity of stone chip samples includes a fixing frame, which consists of a base 1 and a top plate 2 and three uniformly fixed between the base and the top plate. Vertically arranged guide rods 3 are formed. A vertically telescopic hydraulic cylinder 4 is fixed in the center of the base. The cylinder body of the hydraulic cylinder is fixedly connected with the base. The piston rod end of the hydraulic cylinder is fixed with a horizontally arranged lower pressure plate 5 . A transparent sample cylinder 6 is installed above the first pressing plate among the three guide rods, and the sample cylinder is made of a transparent material, so that the filling height of the stone chip sample can be visually measured. The peripheral wall of the sample cylinder is provided with a height scale line 7 along the axial direction, which makes it more convenient ...

Embodiment 2

[0058] A method using a test apparatus for determining the porosity of stone chip samples, comprising the steps of:

[0059] (1) Sieve the test stone chips to obtain stone chip samples with different particle sizes, and weigh the particle size r 1 It is a 1.18mm stone chip sample with a mass of 3705.8g, and the sample cylinder is weighed as 2346.6g;

[0060] (2) Fix the sample cylinder 6 in step (1) on the mounting plate 9 through the connecting bolt 16, and remove the positioning bolts 11 on the two mounting plates so that the two mounting plates can go up and down along the guide rod 3 Sliding, first weigh 1235.27g of stone chip sample and fill it in the sample cylinder, control the extension of the piston rod of the hydraulic cylinder, and the hydraulic cylinder drives the sample cylinder to rise so that the upper platen moves downward relative to the sample cylinder and then squeezes The stone chip sample in the sample cylinder is made to compact the stone chip sample to ...

Embodiment 3

[0077] A method using a test apparatus for determining the porosity of stone chip samples, comprising the steps of:

[0078] (1) Sieve the test stone chips to obtain stone chip samples of different particle sizes, weigh the stone chip samples with a particle size of 1.18mm and a mass of 4453.0g, and record the weight of the sample cylinder as 2346.6g;

[0079] (2) Fix the sample cylinder 6 in step (1) on the mounting plate 9 through the connecting bolt 16, and remove the positioning bolts 11 on the two mounting plates so that the two mounting plates can slide up and down along the guide rod 3 , first weigh 1484.33g of stone chip sample and fill it in the sample cylinder, control the extension of the piston rod of the hydraulic cylinder, and the hydraulic cylinder drives the sample cylinder to rise so that the upper platen moves downward relative to the sample cylinder and then squeezes the test tube. The stone chip sample in the sample cylinder is made to compact the stone chi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com