A Two-lane Deformation Control Method of Reserved Pressure Relief Observation Borehole and Combined Grouting

A technology of deformation control and grouting, which is applied in earthwork drilling, shaft equipment, wellbore lining, etc., can solve the problems of inconsistency, many blind areas of grouting diffusion range, and difficult evaluation of grouting effect, so as to avoid blind grouting, The effect of avoiding large-scale high-pressure air phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

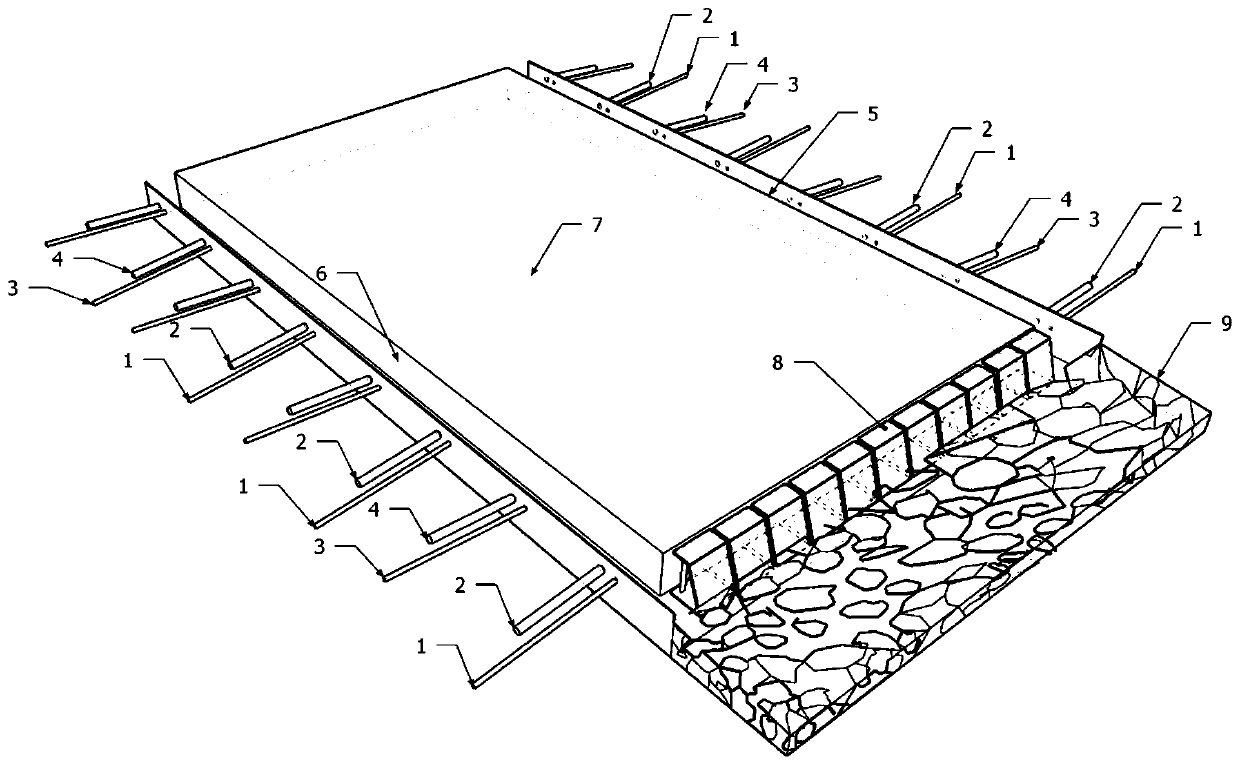

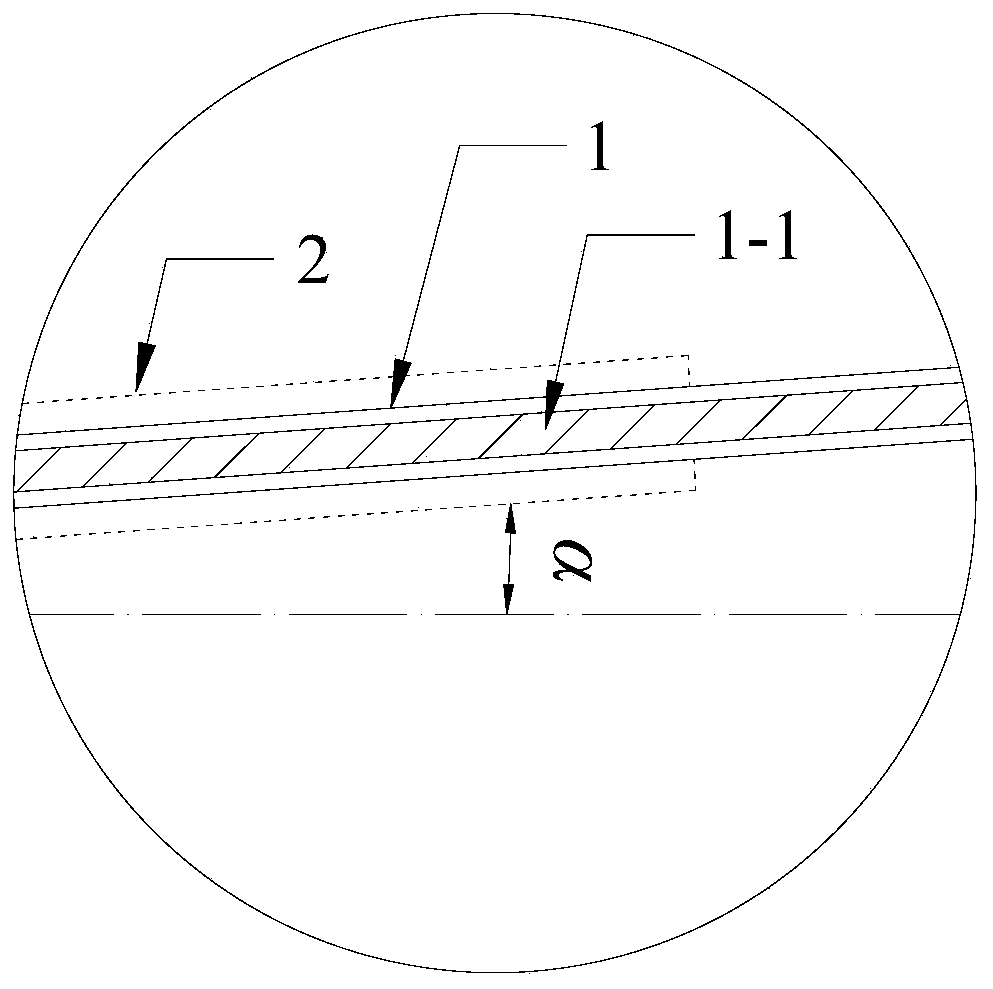

[0030] The two-lane deformation control method of reserved pressure relief observation drilling and joint grouting of the present invention includes upward grouting drilling 1, upward pressure relief observation drilling 2, downward grouting drilling 3, downward unloading The pressure observation borehole 4, wherein the upward grouting borehole 1 and the upward pressure relief observation borehole 2 are located on the non-recovery side of the transportation roadway 5 on the side of the working face 8; the downward grouting borehole 3 and the downward pressure relief borehole The observation borehole 4 is located on the non-recovery side of the return airway 6 on the side of the working face 8; the inner wall of the observation borehole is sprayed with fluorescent materials, and the specific steps are as follows:

[0031] a. During the excavation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com