A power nipple assembly of a double-layer drill string anti-deflection and straight drilling tool

A technology for drilling tools and power nipples, which is applied in directional drilling, engine components, engine lubrication, etc., and can solve problems such as complex structure, poor reliability, and inability to withstand high temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

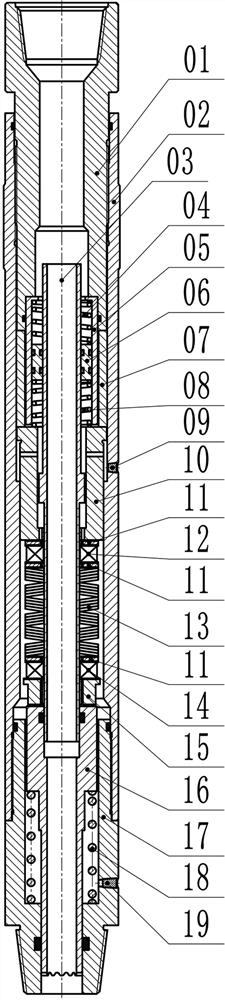

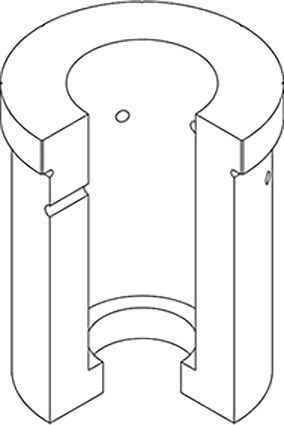

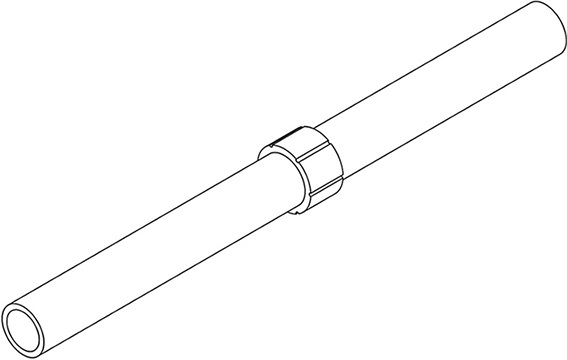

[0023] Such as figure 1 As shown, the power nipple assembly of a pressure-injection double-layer drill string anti-deviation straight drilling tool of the present invention consists of an upper joint (01), a body (02), a center pipe (03), a spring I (04), Piston cylinder (05), piston (06), power transmission cylinder I (07), spring II (08), oil plug I (09), power transmission cylinder II (10), thrust washer (11), rolling elements Ⅰ (12), Disc Spring Set (13), Rolling Element Ⅱ (14), Thrust Pad (15), Power Transmission Tube Ⅲ (16), Drill String Joint (17), Spring Ⅲ (18), Oil Plug II (19) composition. Both the upper outer wall and the lower inner wall of the drill string joint (17) are provided with sealing ring grooves and O-shaped sealing rings are installed in the grooves, and the drill string joint and the inner wall of the body (02) and the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com