Construction method of recyclable soil nail split mounting type flexible surface layer wall

A construction method and flexible surface technology, applied in excavation, water supply installations, infrastructure engineering, etc., to achieve the effects of less environmental pollution, reduction of grouting and shotcrete steps, and easy construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

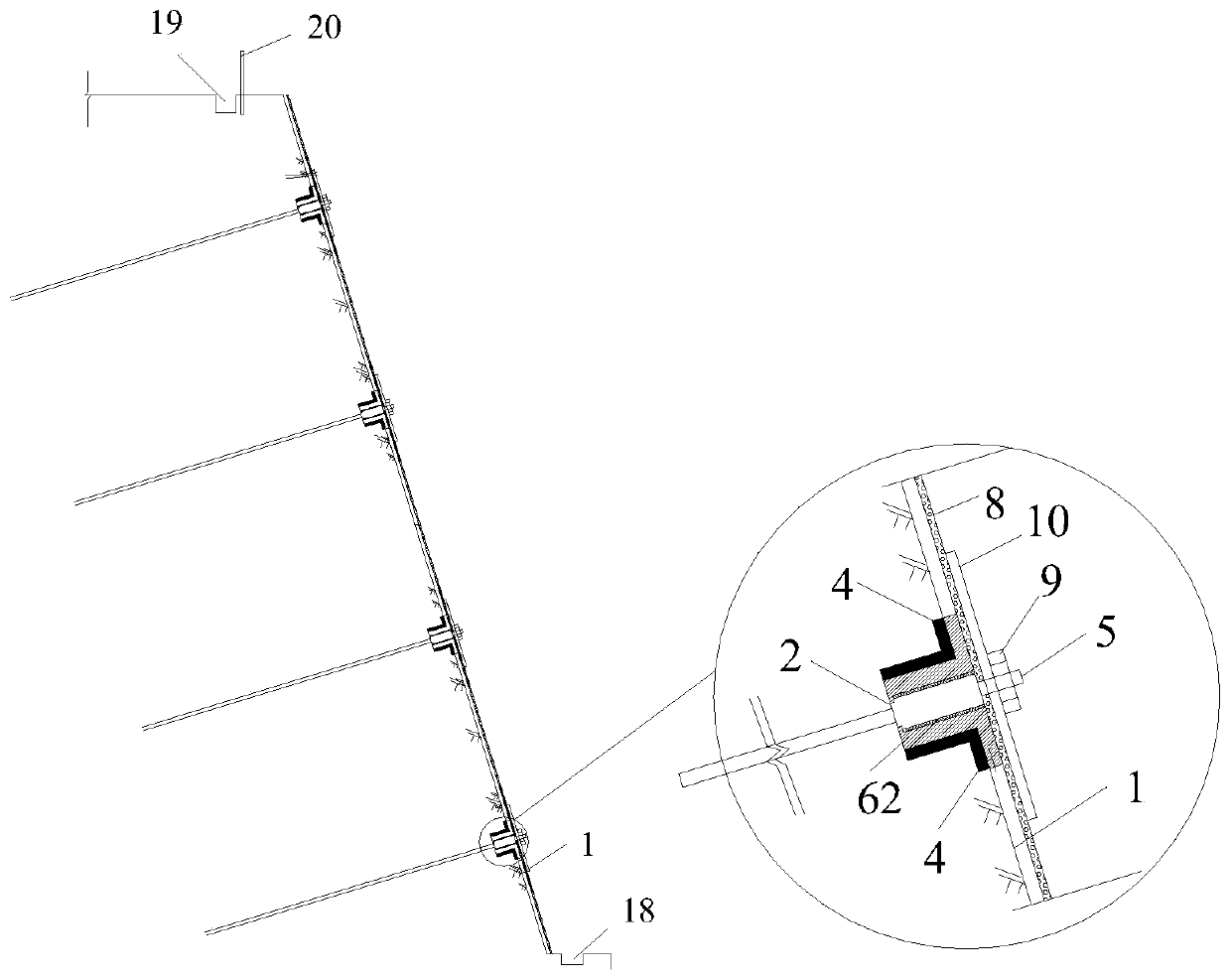

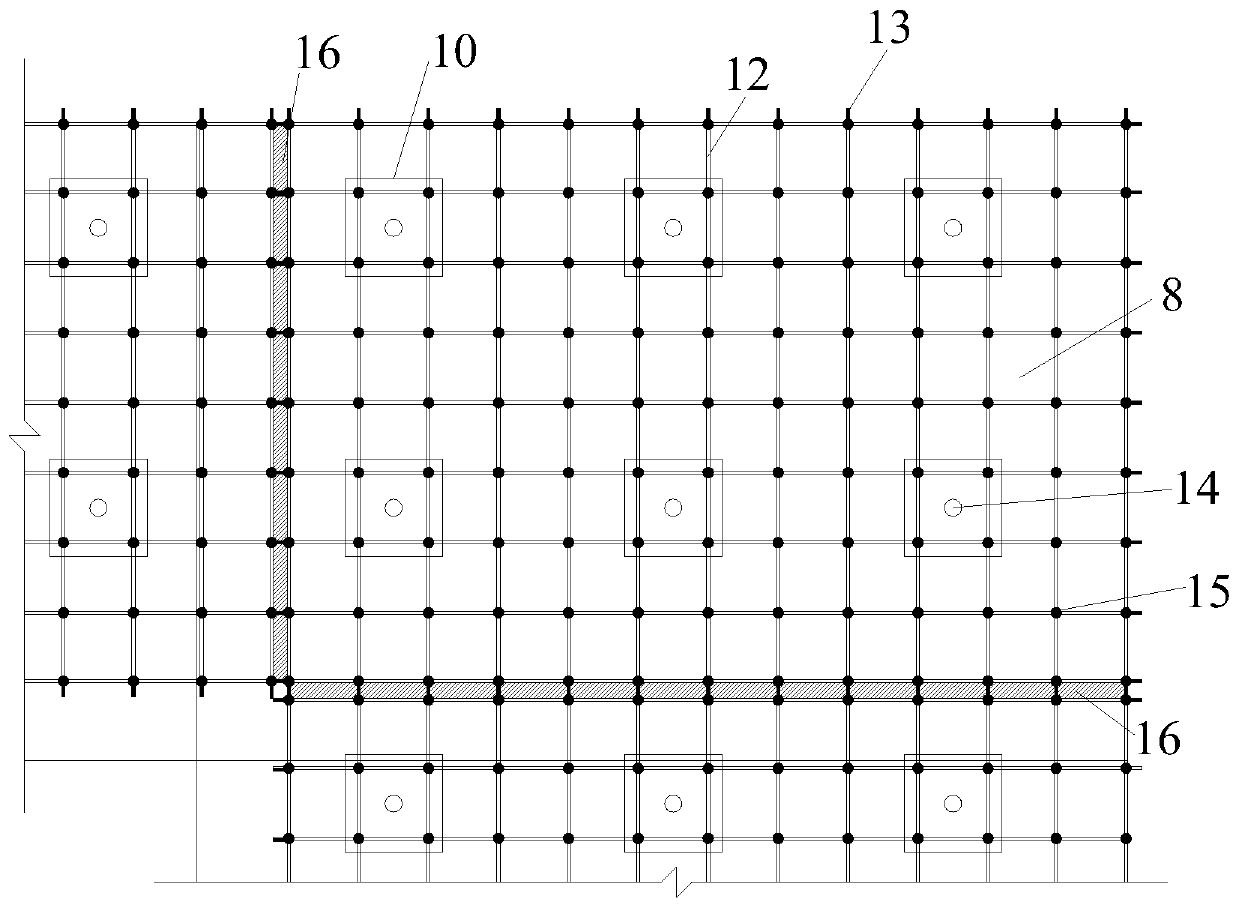

[0045] In order to deepen the understanding of the present invention, reference will be made to Figure 1 to Figure 14 , the embodiments of the present invention are described in detail, the following embodiments are implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

[0046] combined with figure 1 As shown, the present invention relates to a recyclable soil nail assembled flexible surface wall, which includes a foundation pit slope 1, soil nails 5, an assembled flexible surface and a transverse connecting body.

[0047] combined with figure 1 And attached Figure 4 As shown, there are multiple sets of transverse connecting bodies and they are arranged at intervals up and down on the side slope 1 of the foundation pit. combined with figure 1 and attached Figure 4~7 As shown, each group of horizontal connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com