Novel mineralization reactive dyeing technology

A technology of reactive dyeing and reactive dyes, applied in the field of new mineralized reactive dyeing technology, can solve the problems of poor dyeing efficiency, uneven dyeing, complex production process, etc., and achieve the effect of ensuring dyeing, improving dyeing efficiency and shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0074] Dust removal for dyed fabrics: The fabrics used for mineralization reactive dyeing are dedusted and collected for later use.

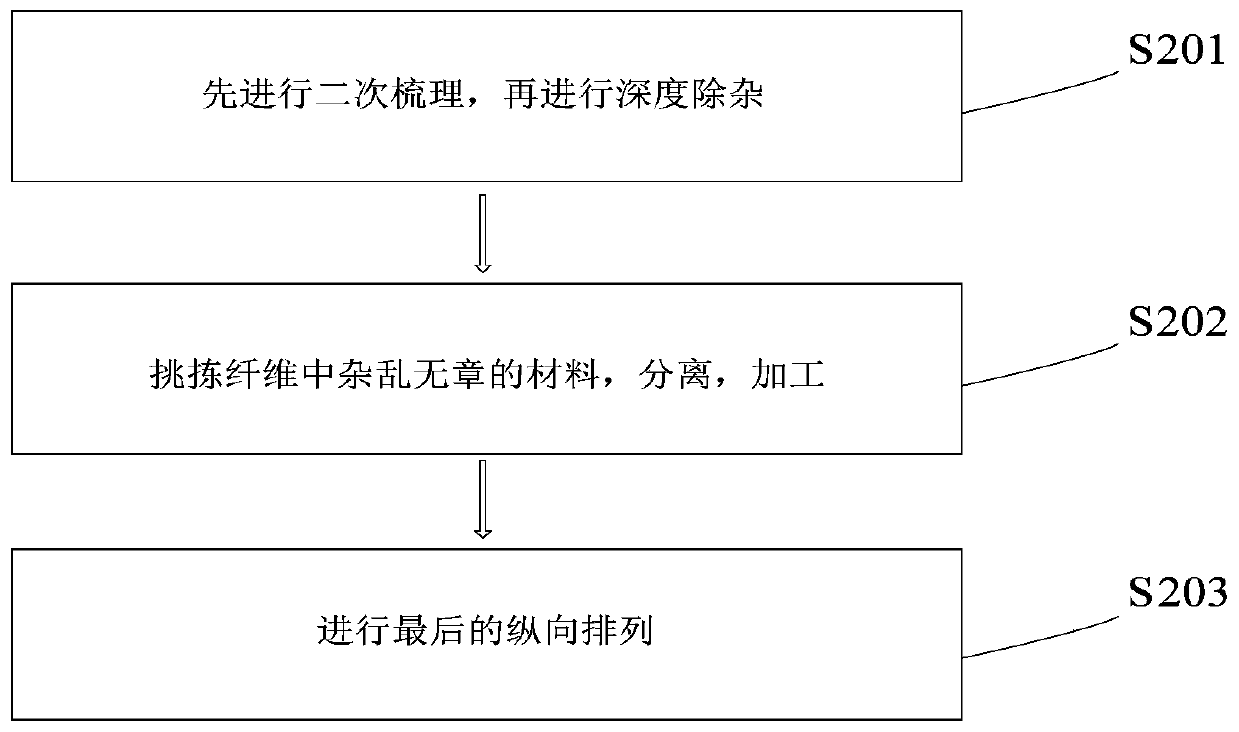

[0075] The pretreatment process of dyed fabric: the described pretreatment process of dyed fabric includes the following steps:

[0076] S201: Washing of dyed fabrics: place the dyed fabrics in a water bath, add hot water to it, and keep it for 20 to 25 minutes after boiling; then add glacial acetic acid to the water bath to cool down to 50°C to 60°C time and hold for between 5 and 10 minutes.

[0077] S202: Pickling of dyed fabrics: adding sodium carbonate and hydrogen peroxide to a water bath for pickling to soften and remove impurities from the dyed fabrics, thereby improving the dyeing efficiency and coloring effect of the fabrics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com