Method for extracting wormwood essential oil by using deep congruent melting solvent

A technology of deep eutectic solvent and wormwood essential oil, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of high industrial equipment requirements, difficulty in large-scale commercial use, and long extraction time of the extraction method, and achieve rich components, Effect of changing permeability and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

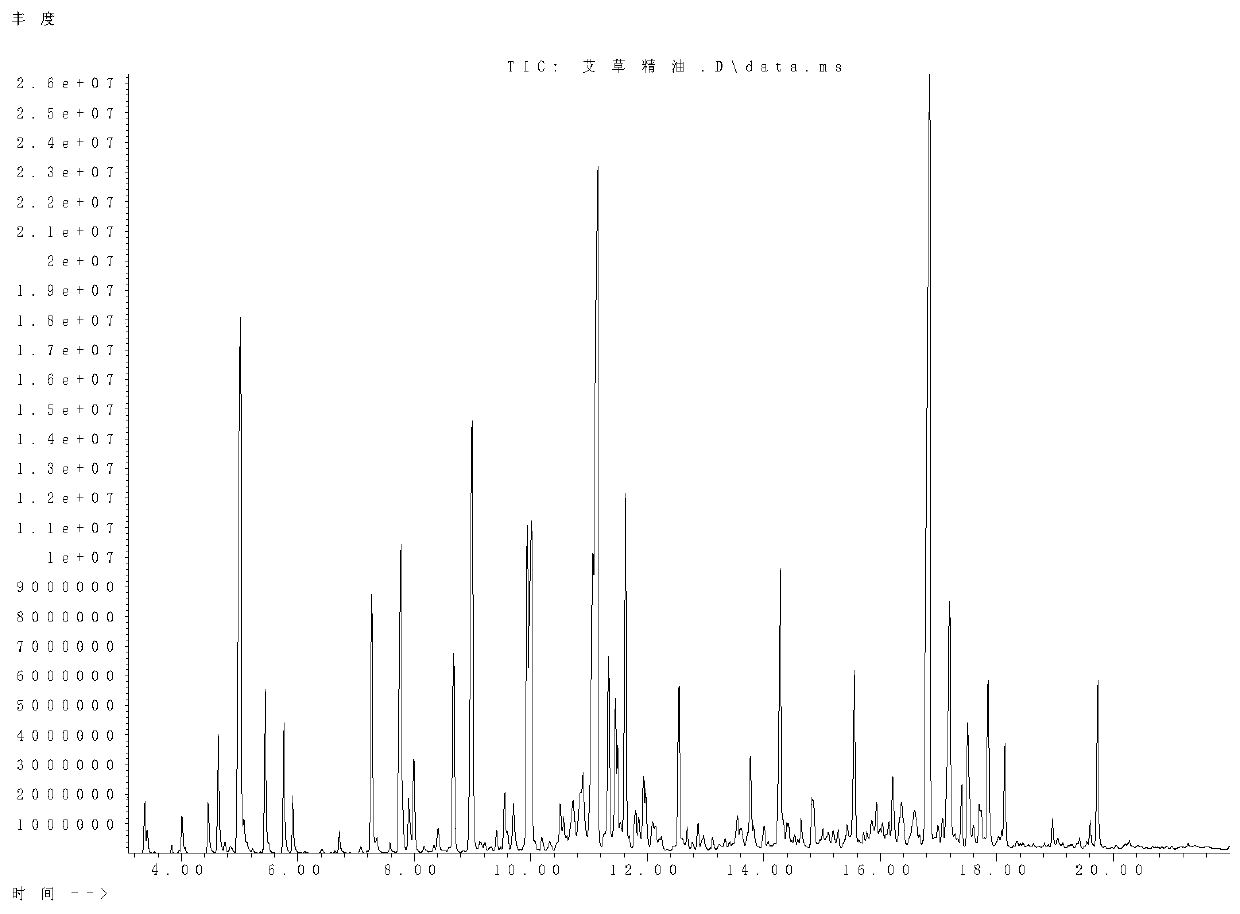

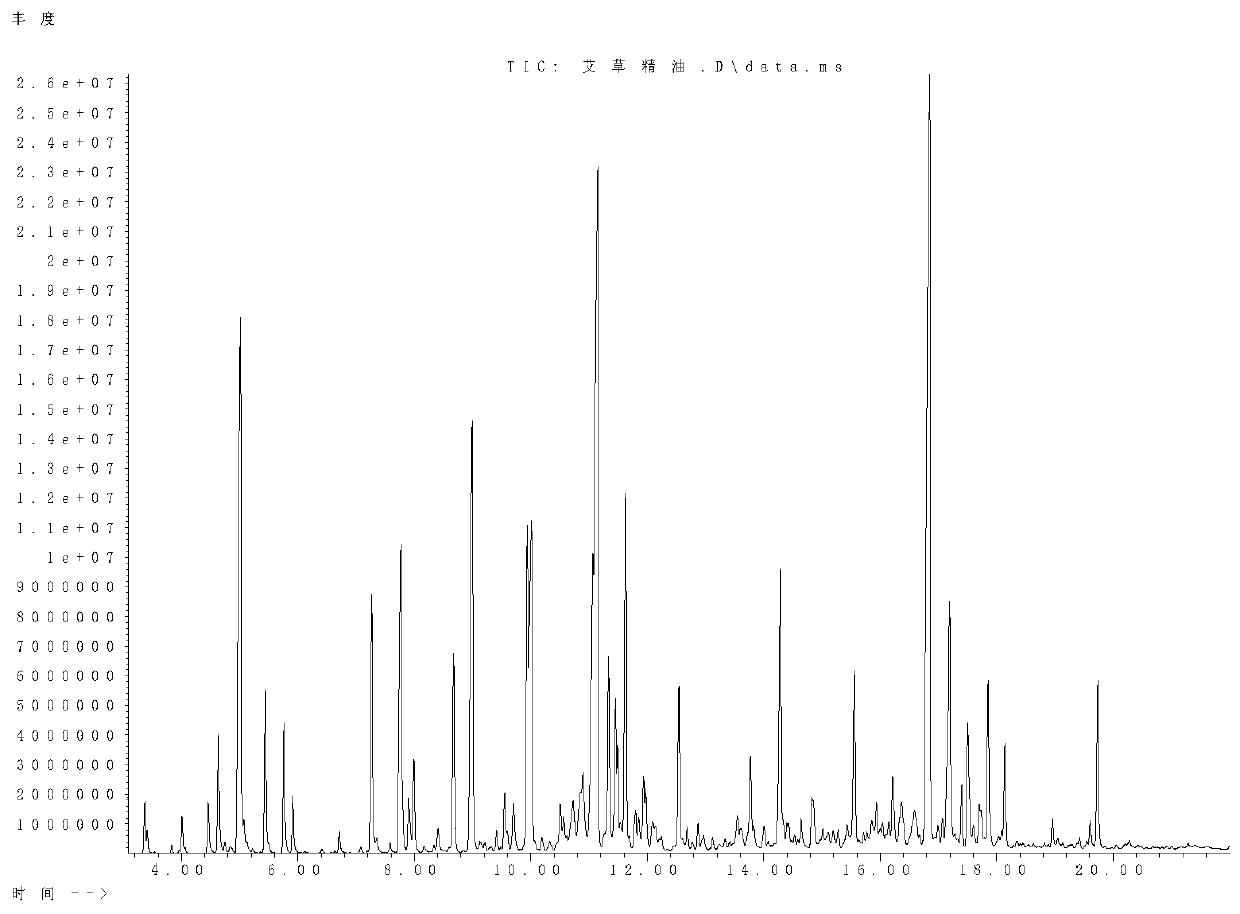

Image

Examples

preparation example Construction

[0023] The raw materials for the preparation of the deep eutectic solvent include choline chloride, glycerin and water.

[0024] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0025] In the present invention, the molar ratio of the choline chloride to glycerol is preferably 1:(1.8-2.2), more preferably 1:(1.9-2.1), most preferably 1:2.0; the choline chloride The volume ratio of the total volume of glycerol to water is preferably (6-8):(2-4), more preferably (6.5-7.5):(2.5-3.5), most preferably 7:3.

[0026] In the present invention, the preparation method of the deep eutectic solvent preferably comprises the following steps:

[0027] A mixture of choline chloride and glycerol was mixed with water under stirring to obtain a deep eutectic solvent.

[0028] In the present invention, the preparation method of the mixture of the choline chloride and glycerin is prefera...

Embodiment 1

[0037] Dry the dried leaves of wormwood at 40°C until the quality is constant, and crush them through a 60-mesh sieve to obtain wormwood powder (stored at 4°C);

[0038] Mix 140g (1mol) choline chloride with 184g (2mol) glycerin, stir (85°C, 300rpm) to a colorless transparent liquid; under the above stirring conditions, mix the colorless transparent liquid with water at a volume ratio of 7:3 Mix to obtain a deep eutectic solvent;

[0039] Mix 40g of wormwood powder with 800mL of deep eutectic solvent, distill for 5h under slightly boiling conditions, dry the obtained fraction with anhydrous sodium sulfate, and filter to obtain wormwood essential oil (stored at 4°C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com