Degradable aggregate having fertilizer efficiency slow releasing performance and preparation method thereof

A slow-release performance and aggregate technology, applied in the field of degradable aggregate and its preparation, can solve the problems of concrete cracking, reduced porosity, unable to meet the needs of plants, etc., and achieves loose structure, high activity, good fertilizer effect slow release and The effect of degradable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

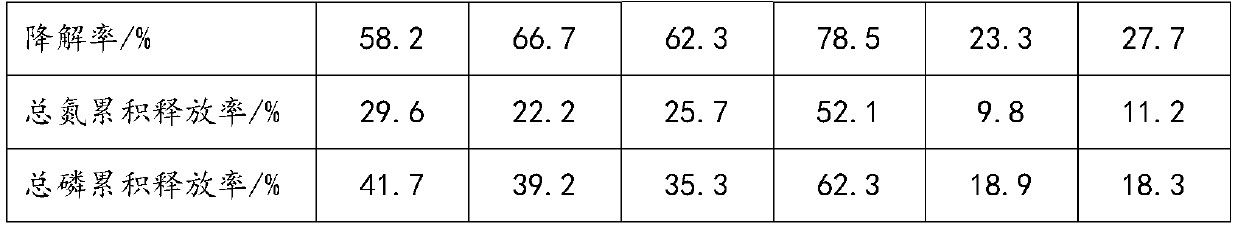

Examples

Embodiment 1

[0031] A preparation method of degradable aggregate with fertilizer effect slow-release performance, comprising the steps of:

[0032] (1) Mix 2 parts of cellulose ether, 2 parts of soluble starch and 5 parts of water evenly, then add 75 parts of tartaric acid in 2 times and stir for 15 minutes, dry at 60°C for 10 minutes, and grind for 10 minutes to obtain Coated tartaric acid;

[0033] (2) Stir 45 parts of magnesium oxide powder, 15 parts of ammonium dihydrogen phosphate, 17 parts of water and 2 parts of sodium fatty acid in an ammonia atmosphere and a closed container at 30°C until a large amount of magnesium ammonium phosphate hexahydrate precipitates appear, bake Dry and grind again for 10 minutes to obtain magnesium ammonium phosphate hexahydrate powder;

[0034] (3) Stir 5 parts of aluminum powder and 2 parts of water for 5 minutes, add 50 parts of magnesium ammonium phosphate hexahydrate powder, 5 parts of coated tartaric acid, 5 parts of sodium bicarbonate and 5 part...

Embodiment 2

[0036] A preparation method of degradable aggregate with fertilizer effect slow-release performance, comprising the steps of:

[0037] (1) Mix 5 parts of cellulose ether, 10 parts of soluble starch and 10 parts of water evenly, then add 91 parts of tartaric acid in 6 times and stir for 60 minutes, dry at 80°C for 30 minutes, and grind for 30 minutes to obtain Coated tartaric acid;

[0038] (2) Stir 60 parts of magnesium oxide powder, 25 parts of ammonium dihydrogen phosphate, 38 parts of water and 8 parts of sodium fatty acid in an ammonia atmosphere and a closed container at 50°C until a large amount of magnesium ammonium phosphate hexahydrate precipitates appear, bake Dry and grind again for 30 minutes to obtain magnesium ammonium phosphate hexahydrate powder;

[0039] (3) Stir 10 parts of aluminum powder and 6 parts of water for 10 minutes, add 75 parts of magnesium ammonium phosphate hexahydrate powder, 10 parts of coated tartaric acid, 10 parts of sodium bicarbonate and ...

Embodiment 3

[0041] A preparation method of degradable aggregate with fertilizer effect slow-release performance, comprising the steps of:

[0042] (1) Mix 3 parts of cellulose ether, 5 parts of soluble starch and 8 parts of water evenly, then add 80 parts of tartaric acid in 4 times and stir for 45 minutes, dry at 70°C for 20 minutes, and grind for 20 minutes to obtain Coated tartaric acid;

[0043] (2) Stir 50 parts of magnesium oxide powder, 20 parts of ammonium dihydrogen phosphate, 32 parts of water and 6 parts of fatty acid sodium in an ammonia atmosphere and a closed container at 40°C until a large amount of magnesium ammonium phosphate hexahydrate precipitates appear, bake Dry and grind for 20 minutes to obtain magnesium ammonium phosphate hexahydrate powder;

[0044] (3) Stir 7 parts of aluminum powder and 4 parts of water for 6 minutes, add 60 parts of magnesium ammonium phosphate hexahydrate powder, 7 parts of coated tartaric acid, 8 parts of sodium bicarbonate and 12 parts of Po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com