Method for cleaning recycled iron in wet-process zinc smelting technology

A technology for zinc hydrometallurgy and iron recovery, applied in the direction of ferric sulfate, nanotechnology, etc., can solve the problems of affecting recovery and easy access to jarosite, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A method for cleaning and recovering iron in a zinc hydrometallurgy process of the present invention, comprising:

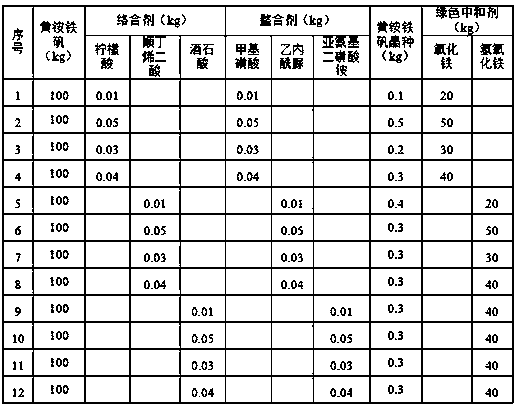

[0023] In the iron-containing zinc sulfate solution, add complexing agent, chelating agent, jarosite seed crystals, ammonium carbonate and green neutralizer to sink vitriol, liquid-solid separation to obtain jarosite precipitation and zinc sulfate solution, jarosite precipitation through fast Burn to get nano iron sulfate. The raw material formula of sinking alum is shown in Table 1.

[0024]

[0025] In Example 1-Example 12 of the present invention, the mass content of the valuable metal zinc in the jarosite slag is less than 0.5%, and the content of indium and silver is less than 5g / t.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com