Injection molding system and method

A technology of injection molding and molding machine, which is applied in the field of molding system and molding to achieve the effect of improving yield and accurately adjusting injection molding parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

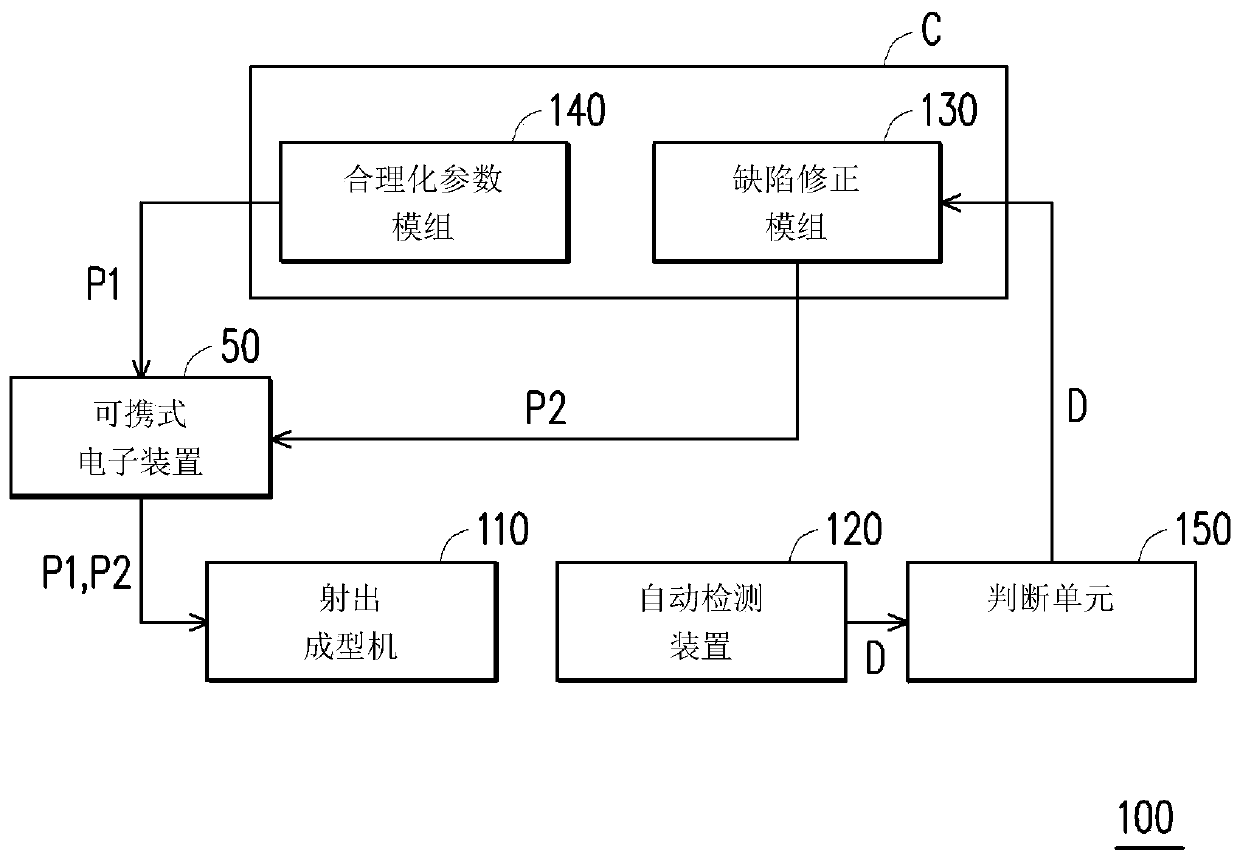

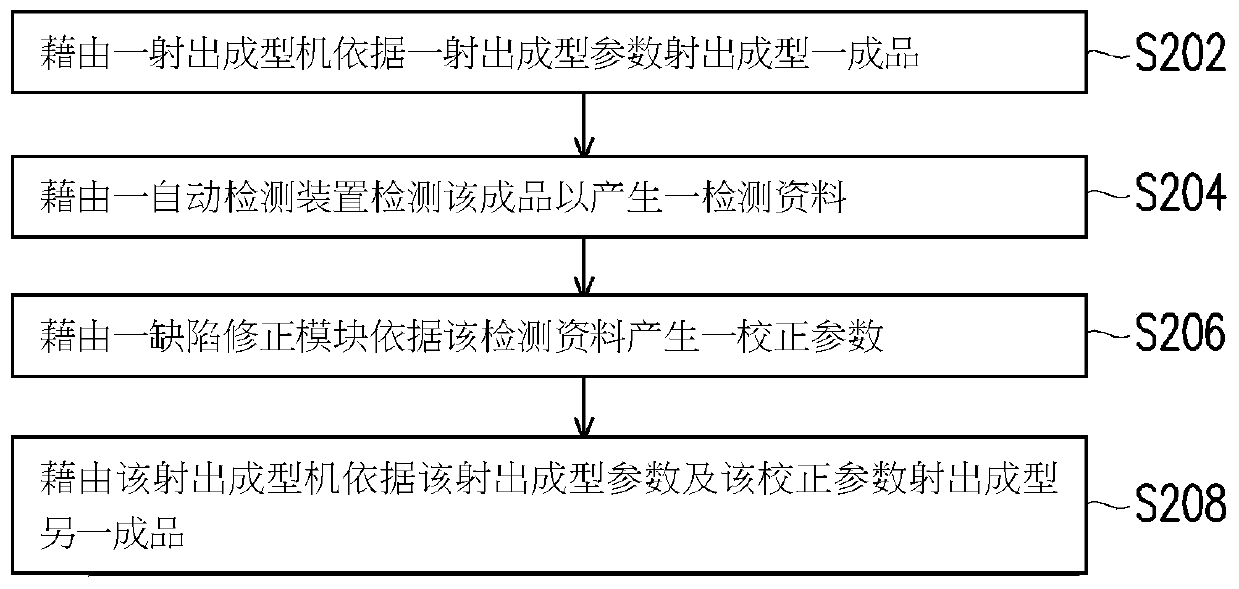

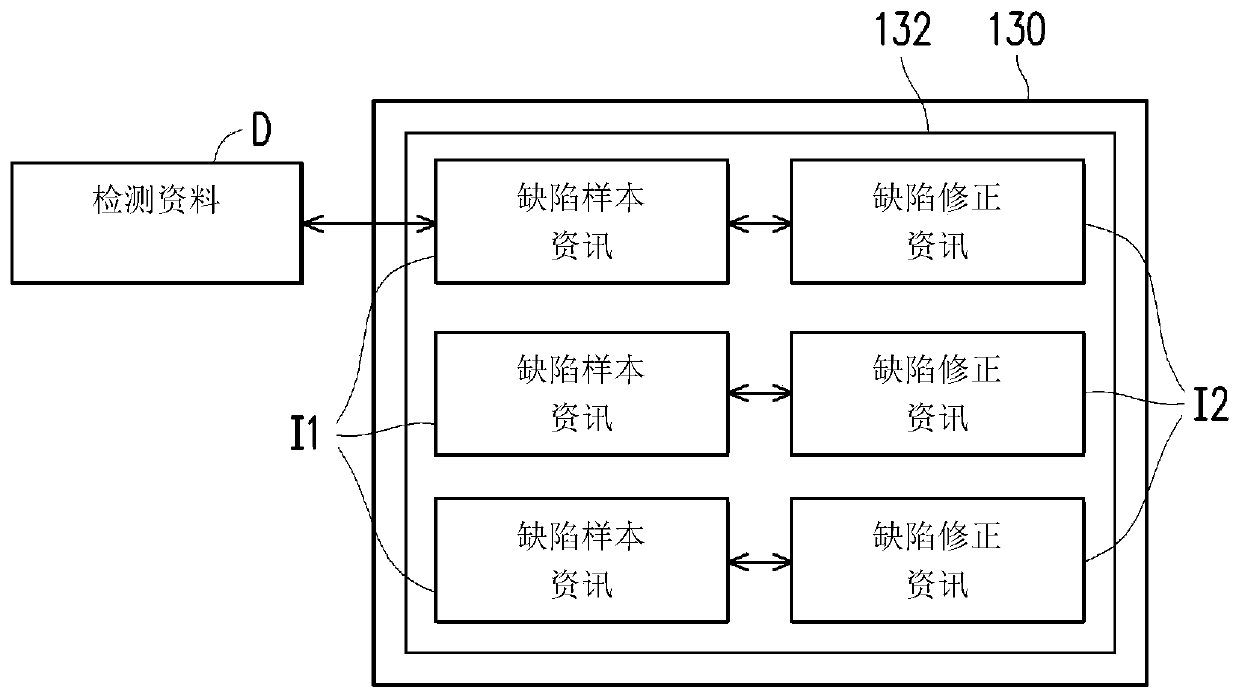

[0032] figure 1 It is a schematic diagram of an injection molding system according to an embodiment of the present invention. Please refer to figure 1 , the injection molding system 100 of this embodiment includes an injection molding machine 110 , an automatic inspection device 120 and a defect correction module 130 . The injection molding machine 110 is suitable for injection molding a finished product, such as a plastic product, according to the injection molding parameter P1. The automatic inspection device 120 is suitable for inspecting the finished product to generate inspection data D. The defect correction module 130 is, for example, located in the cloud C and is suitable for generating a correction parameter P2 according to the inspection data D. The injection molding machine 110 is suitable for injection molding another product according to the injection molding parameter P1 and the correction parameter P2.

[0033] Compared with the conventional detection of defe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com