A multi-wire EDM machining method for ruled curved surfaces

A ruled surface, cutting processing technology, applied in the field of ruled surface processing, can solve the problems of complex feeding, low efficiency, large electrode loss, etc., to achieve the effect of low electrode loss, simple feeding process, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

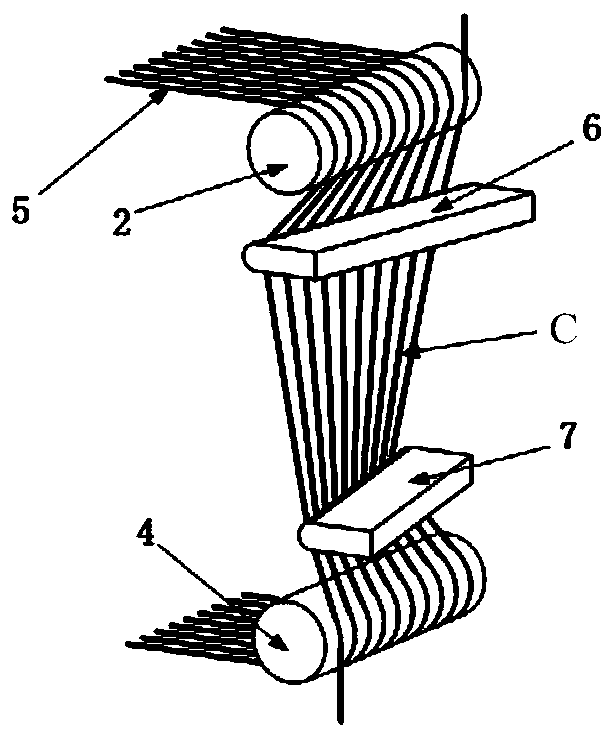

[0020] Different types of ruled surfaces can be processed according to the different undulations of the sides of the wire pressing rod. This embodiment is mainly used for the processing of spiral surface ruled surfaces, that is, the edges of the splines of the upper and lower surfaces are straight lines.

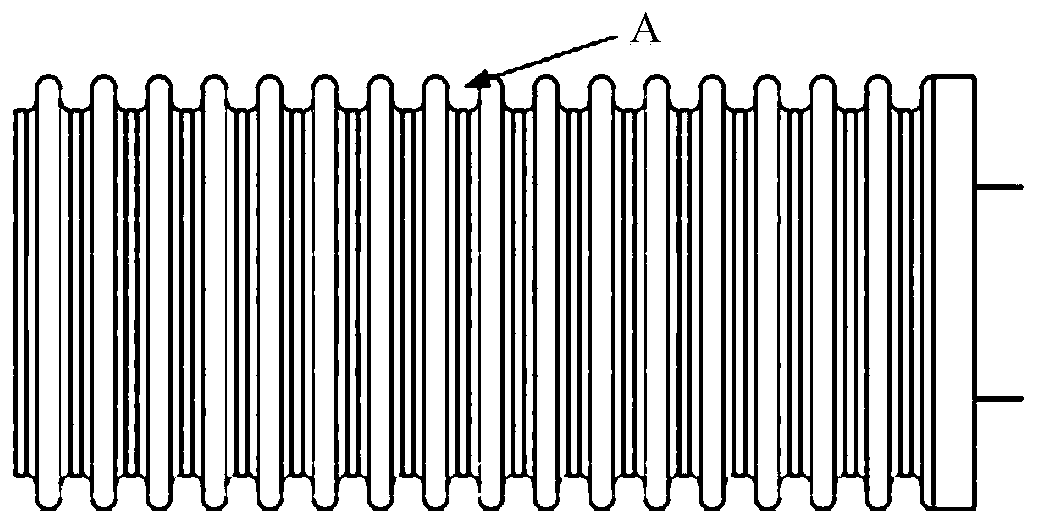

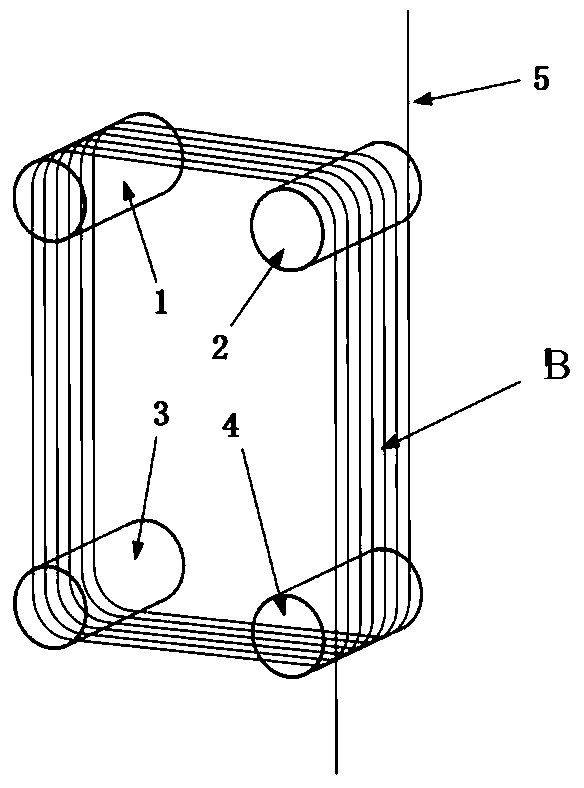

[0021] see Figure 1~4 , the processing device involved in this embodiment includes a wire electric discharge machine tool, multi-groove wire rollers 1 to 4, electrode wire 5 and curved surface spline plates 6 and 7, and the specific parts appearance and implementation steps are as follows:

[0022] 1) Cr12 die steel is selected as the material of the multi-groove wire roller, and the side view partial diagram of the multi-groove wire roller is as follows figure 1 , the electrode wire 5 is a molybdenum wire with a diameter of 0.18 mm, and the curved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com