A method for preparing synthetic diamond column

A technology of artificial diamond and synthetic column, which is applied in the application of ultra-high pressure process, etc., can solve the problems of not specifying the preparation method in detail, the uniformity cannot be guaranteed, and prolong the mixing time, so as to save process time, ensure easy control and Reproducibility, effect of reducing twinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

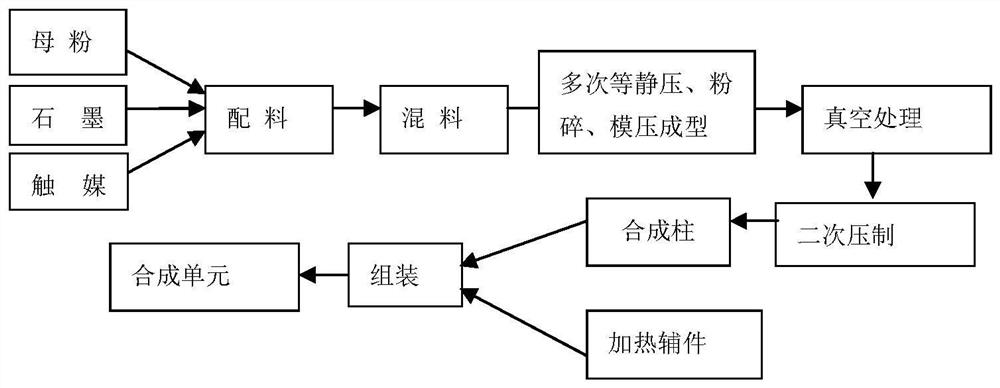

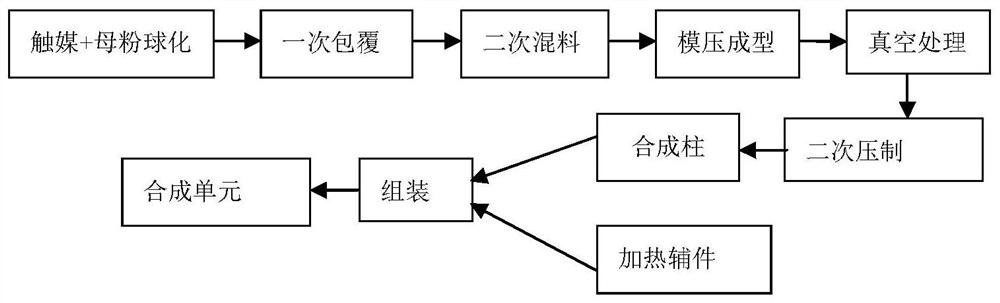

Method used

Image

Examples

Embodiment 1

[0046] Take by weighing alloy composition and be FeNi30, particle size-200 purpose catalyst powder 50 kilograms, mother powder (-500 purpose diamond crystal powder 50wt%,-600 purpose superfine cobalt powder 25wt%,-600 purpose superfine chromium powder 25wt% mix homogeneously ) 0.4 kg, put into the VH-10 shaping machine, adjust the shaping speed to be 1000 rev / min, and the time is 100 minutes to obtain the catalyst powder after spheroidization; image 3 As shown, it is a schematic diagram of the combination of FeNi30 catalyst powder and master powder and graphite coating. The master powder particles are pressed into or embedded in the surface of the catalyst particles; then take 0.5 kg of ethylene glycol into the spheroidized catalyst and stir evenly, and then Put into 10 kilograms of graphite powders, adjust rotating speed and be 500 rev / mins, obtain composite catalyst particles after mixing for 180 minutes, as Figure 4 Shown is a photo of FeNi30 catalyst particles and graphi...

Embodiment 2

[0048] Take by weighing alloy composition and be FeNi29Co1, particle size-200 purpose catalyst powder 60 kilograms, master powder (-500 purpose diamond crystal powder 60wt%,-600 purpose superfine cobalt powder 20wt%,-600 purpose superfine chromium powder 20wt% mix homogeneously ) 0.5 kg, put into VH-10 shaping machine for spheroidization, adjust the rotating speed to be 900 rpm, and take 120 minutes to obtain the catalyst powder after spheroidization; then get 0.6 kg of ethylene glycol and put it into the shaped catalyst and stir Evenly, then put in 12 kilograms of graphite powder, adjust the rotating speed to 500 rpm, mix for 180 minutes, take it out and put it into the three-dimensional mixer, then weigh 99.4 kilograms of graphite powder and add it to the three-dimensional mixer, so that the weight of catalyst and graphite When the ratio reaches 3.5:6.5, add 1.5 kg of ethylene glycol and mix for 220 minutes to obtain a uniform catalyst and graphite mixed powder; use a 200-ton...

Embodiment 3

[0050] Take by weighing alloy composition and be FeNi25Mn5, particle size-325 purpose catalyst powder 75 kilograms, parent powder (-500 purpose diamond crystal powder 40wt%,-600 purpose superfine cobalt powder 30wt%,-600 purpose superfine chromium powder 30wt% mix powder) 0.8 kg, put it into VH-10 shaping machine, adjust the shaping speed to 800 rpm, and shape for 150 minutes to obtain the catalyst powder after spheroidization; then take 0.8 kg of ethylene glycol and put it into the shaped catalyst Stir evenly, then put in 15 kilograms of graphite powder, adjust the rotating speed to 500 rpm, take it out after mixing for 180 minutes and put it into a three-dimensional mixer, then weigh 160 kilograms of graphite powder and add it to a three-dimensional mixer to make the catalyst and graphite When the weight ratio reaches 3:7, add 1.8 kg of ethylene glycol, and mix for 250 minutes to obtain a uniform catalyst and graphite mixed powder; use a 200-ton four-column press, select a Φ5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com