Preparation method of graphene oxide/attapulgite/polyvinyl alcohol ceramic matrix composite membrane

A technology of ceramic matrix and attapulgite, applied in chemical instruments and methods, permeation/dialysis water/sewage treatment, membrane technology, etc., can solve problems such as hindering the dispersion of GO nanosheets, achieve improved membrane flux, and simple preparation process , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 10 g of 3-aminopropyl-triethoxysilane in 1 L of absolute ethanol to form a mixed solution of 10 g / L, and soak the Al2O3 ceramic substrate with a pore size of 0.5 μm in the mixed solution for 5 h , rinsed with deionized water after being taken out, and dried in an oven at 120 °C for 3 h.

[0023] A small amount of PVA was dissolved in water under the condition of heating and stirring at 80 °C to prepare a 1 wt% mass concentration solution for later use.

[0024] Measure 1 ml of 1 mg / L graphene oxide dispersion, 5 mg of attapulgite and 60 mg of 1 wt% PVA solution at a ratio of m(GO:ATP)=1:5, mix and dilute to 15 mL, and the solution was stirred for 30 min, at which point the total mass of the membrane was 6.6 mg.

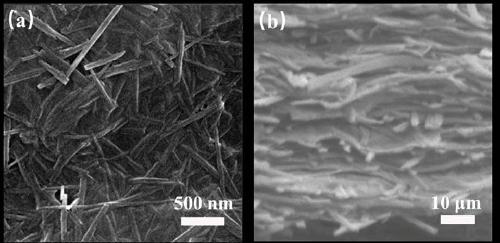

[0025] Slowly pour the solution into a suction filter bottle, vacuum filter it on the Al2O3 ceramic substrate, completely drain it to form a film, take it out, put it in an oven for 2 h at 50 °C, and prepare GO / ATP / PVA (10%) Composite film such as f...

Embodiment 2

[0027] Dissolve 10 g of 3-aminopropyl-triethoxysilane in 1 L of absolute ethanol to form a mixed solution of 10 g / L, and soak the Al2O3 ceramic substrate with a pore size of 0.2 μm in the mixed solution for 5 h , rinsed with deionized water after being taken out, and dried in an oven at 120 °C for 3 h.

[0028] A small amount of PVA was dissolved in water under the condition of heating and stirring at 80 °C to prepare a 1 wt% mass concentration solution for later use.

[0029] Measure 1 ml of 1 mg / L graphene oxide dispersion, 20 mg of attapulgite and 105 mg of 1 wt% PVA solution at a ratio of m(GO:ATP)=1:20, mix and dilute to 15 mL, and the solution was stirred for 30 min, at which point the total mass of the membrane was 22.05 mg.

[0030] Slowly pour the solution into a suction filter bottle, filter it on the Al2O3 ceramic substrate by vacuum suction, completely drain it to form a film, take it out, put it in an oven for 2 h at 50 °C, and prepare GO / ATP / PVA (5%) Composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com