Alkyl chitosan-graphene oxide composite sponge and preparation method and application thereof

A technology of combining alkyl chitosan and graphene, which is applied in the field of medical materials, can solve the problems such as the decline of blood absorption performance, and achieve the effects of shortening hemostasis time, reducing blood loss, and enhancing blood absorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides the preparation method of the alkyl chitosan-graphene oxide composite sponge described in the above technical scheme, comprising the following steps:

[0040] (1) chitosan solution is mixed with aldehyde compounds, then adding reducing agent, after reaction, alkyl chitosan is obtained;

[0041] (2) mixing the alkyl chitosan, acetic acid, graphene oxide and water, and freeze-drying the obtained mixed material liquid to obtain the alkyl chitosan-graphene oxide composite sponge.

[0042] In the invention, the chitosan solution is mixed with the aldehyde compound, and then a reducing agent is added to obtain the alkyl chitosan after reaction. In the present invention, described chitosan solution preferably comprises chitosan, acetic acid, ethanol and water, wherein:

[0043] The mass ratio of said chitosan to water is preferably 1:(80~120), more preferably 1:100;

[0044]The mass ratio of the acetic acid to water is preferably (0.8-1.2)...

Embodiment 1

[0065] (1) Dissolve 2g CS in 200mL of 1% glacial acetic acid aqueous solution, stir at room temperature until completely dissolved, add 75mL of absolute ethanol, and continue stirring for 1h. Add a certain amount of hexanal (the number of moles of chitosan amino groups: the number of moles of hexanal = 1:0.8), and adjust the pH to 5.1. After fully stirring for 4 hours, slowly add sodium cyanoborohydride (aldehyde group: cyanoborohydride Molar ratio of sodium = 1:3). After fully reacting for 4 h, the pH was adjusted to 10 with 10 wt.% NaOH solution. The precipitated product was collected, fully soaked and washed with 50%, 75% and 100% ethanol aqueous solution to remove unreacted alkylaldehyde, and then the product was washed with deionized water until neutral. The product was frozen at -20°C overnight (8h), and freeze-dried (-80°C, 24h) to obtain the final product: AC6 powder with a substitution degree of about 32%, named AC6a;

[0066] (2) Ultrasonic disperse 5 mg of GO in 2...

Embodiment 2~9

[0068] Prepare alkyl chitosan-graphene oxide composite sponge according to the mode of embodiment 1, the composition or consumption of aldehyde compound used are different;

[0069] In addition, in embodiment 4, except preparing composite sponge, also prepare alkyl chitosan sponge, method is identical with the preparation method of composite sponge, and difference is not to add graphene oxide in step (2), all the other according to step ( 1) and (2) to operate. The components and dosages of Examples 2-9 are specifically shown in Table 1.

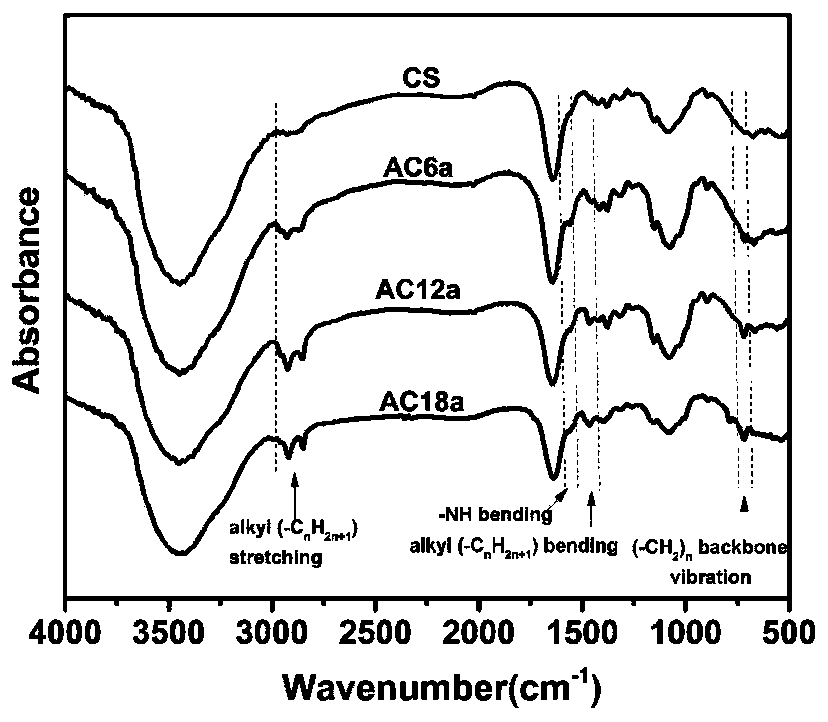

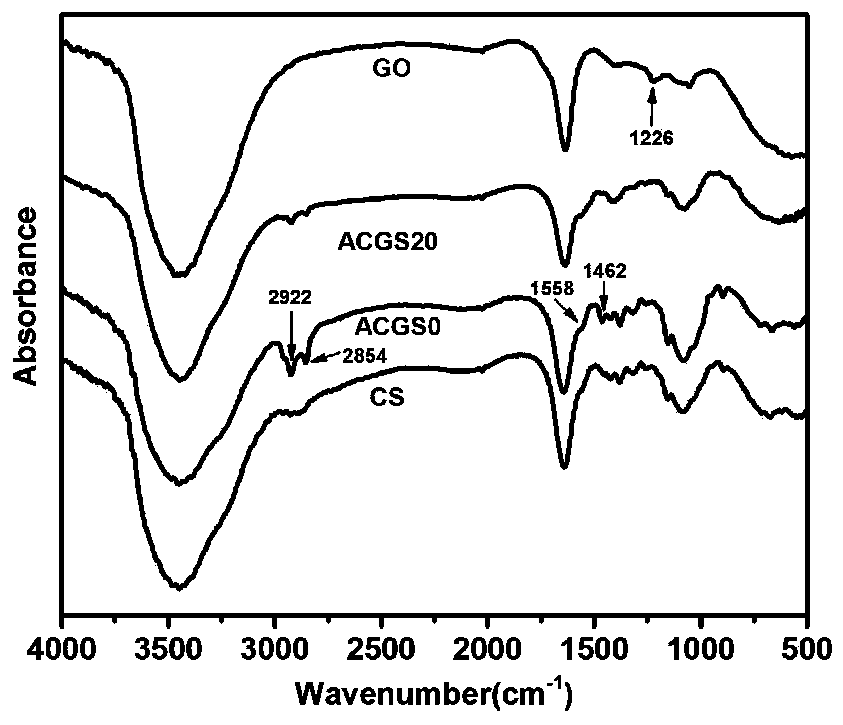

[0070] Utilize the Tensor 37 type infrared spectrometer that Newton company produces, the product obtained in embodiment 1~9 is characterized, the result is as follows figure 1 with 2 shown. figure 1 It is the FTIR comparison chart of chitosan powder and alkyl chitosan powder, which shows the -CH of the product 3 The stretching vibration peak (2900-3000cm -1 ), -CH 2 The stretching vibration peak (2800-2900cm -1 ), the bending vibrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com