A kind of film and preparation method thereof and qled device

A thin film and device technology, applied in the field of quantum dots, can solve the problems of insufficient energy level and exciton binding capacity of quantum dots, low luminous efficiency of QLED devices, concentration quenching, etc., so as to suppress non-radiative energy transfer and concentration quenching. , high-efficiency QLED devices, reducing the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] The preparation method of the thin film of different quantum dot weight percentages in this embodiment comprises the following steps:

[0081] 1) Weigh 20 mg of CdTe / CdZnS core-shell quantum dots and fully dissolve them in 10 mL of chlorobenzene to form a quantum dot solution with a concentration of 2 mg / mL. The quantum yield is 56%;

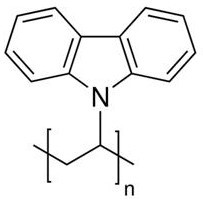

[0082] 2), respectively weigh 40mg, 30mg, 20mg, 10mg, 8mg, 4mg, 2mg, 1mg, 0.5mg, 0.3mg, 0.1mg of PVK (weight average molecular weight: ~1.1 million) fully dissolved in 0.5mL of chlorine benzene;

[0083] 3) Add 0.5mL of the quantum dot solution prepared in step 1) to the above-mentioned PVK chlorobenzene solution and mix thoroughly to form PVK / QD weight concentrations of 40 / 1, 30 / 1, 20 / 1, 10 / 1, 8 / 1, 4 / 1, 2 / 1, 1 / 1, 0.5 / 1, 0.3 / 1, 0.1 / 1 mg / mL chlorobenzene solution;

[0084] 4) In an inert atmosphere, the above-mentioned chlorobenzene solution is spin-coated to form a film, and annealed at 120° C. for 15 minutes to prepare films with diff...

Embodiment 2

[0086] The effect of adding barrier polymer materials on the quantum yield of thin film luminescence

[0087] The luminescence quantum yields of each film in Example 1 are shown in Table 1 below. Compared with the film formed by pure quantum dot material (the last row), different proportions of barrier polymer materials (in this example, PVK) can significantly improve the luminescence quantum yield of the film, from 3% of the pure film to 53%, which is basically close to the luminescence quantum yield of quantum dots in solution, indicating the isolation effect of PVK polymers in the film for quantum dots good. In this example, PVK has a large weight-average molecular weight (1.1 million), and it can be seen that the weight percentage of QDs in a wide range of 2-90% can improve the luminous efficiency.

[0088] Table 1. Luminescence quantum yield of thin films

[0089]

Embodiment 3

[0091] The preparation method of the thin film of different quantum dot weight percentages in this embodiment comprises the following steps:

[0092] 1) Weigh 20 mg of CdTe / CdZnS core-shell quantum dots and fully dissolve them in 10 mL of chlorobenzene to form a quantum dot solution with a concentration of 2 mg / mL. The quantum yield is 56%;

[0093] 2), respectively weigh 40mg, 30mg, 20mg, 10mg, 8mg, 4mg, 2mg, 1mg, 0.5mg, 0.3mg, 0.1mg of PVK (weight-average molecular weight: ~500,000) fully dissolved in 0.5mL of chlorine benzene;

[0094] 3) Add 0.5mL of the quantum dot solution prepared in step 1) to the above-mentioned PVK chlorobenzene solution and mix thoroughly to form PVK / QD weight concentrations of 40 / 1, 30 / 1, 20 / 1, 10 / 1, 8 / 1, 4 / 1, 2 / 1, 1 / 1, 0.5 / 1, 0.3 / 1, 0.1 / 1 mg / mL chlorobenzene solution;

[0095] 4) In an inert atmosphere, the above-mentioned chlorobenzene solution is spin-coated to form a film, and annealed at 120° C. for 15 minutes to prepare films with differen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com