Electric core testing device of electric vehicle

A technology for testing devices and electric vehicles, which is applied in the direction of measuring devices, measuring device casings, measuring electricity, etc., can solve the problems of low efficiency of battery testing, and achieve the effect of fast battery performance testing and monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

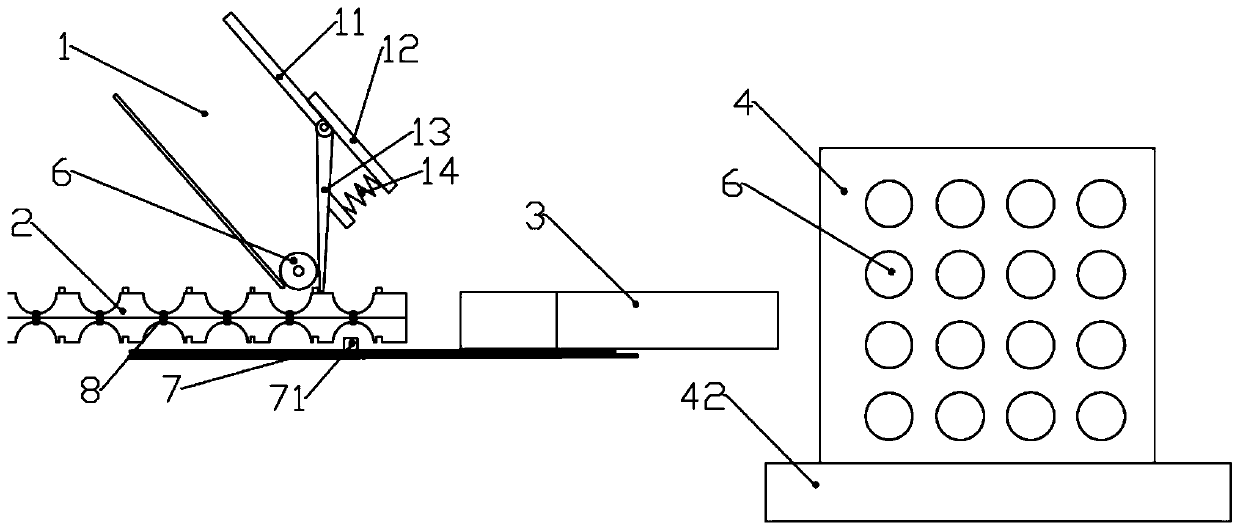

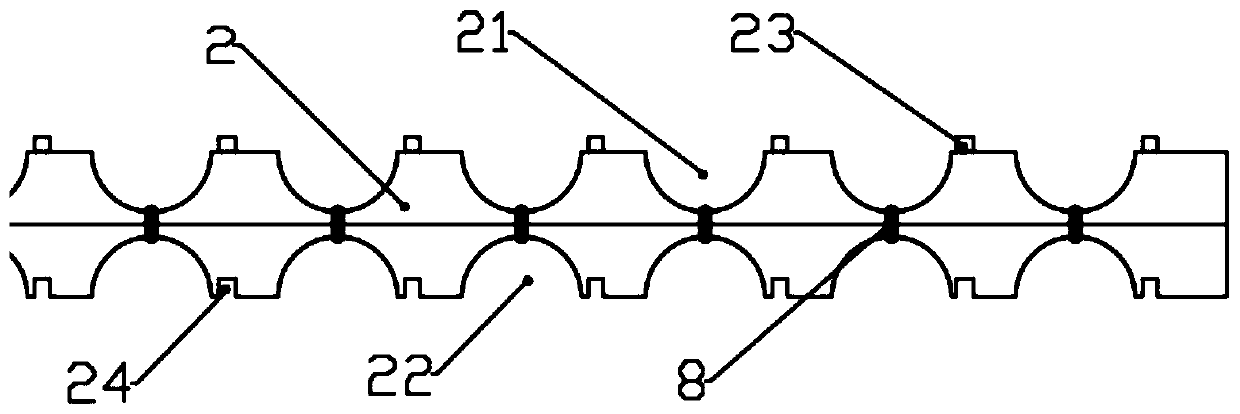

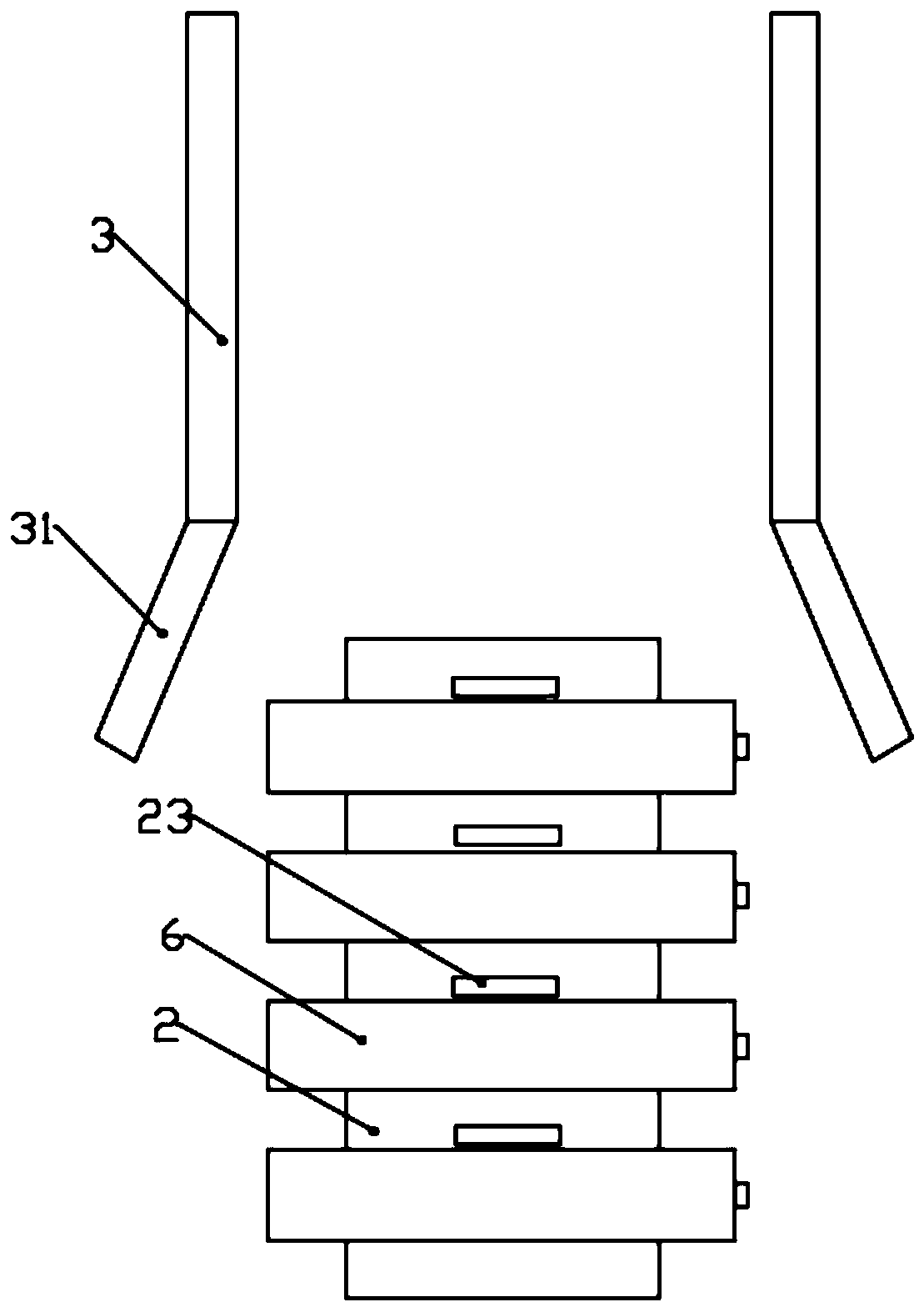

[0025] Such as Figure 1 to Figure 4 As shown: this embodiment discloses a battery test device for electric vehicles: it includes a battery inlet 1, a battery bracket 2, an alignment plate 3 and test components, and the battery inlet 1 includes a sloping plate 11, a hinged plate 13 and spring one 14, the hinged plate 13 is hinged on the lower end of the inclined plate 11, the spring one 14 is connected to the hinged plate 13, the lower end of the battery feed port 1 is connected to the battery support 2, and the upper surface and the lower surface of the battery support 2 are respectively provided with There are an upper battery slot 21 and a lower battery slot 22. The upper surface and the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com