Prefabricated mould for pipe gallery and construction method for pipe gallery

A pipe gallery and mold technology, applied in molds, manufacturing tools, artificial islands, etc., can solve the problems of cumbersome mold assembly, inconvenient construction, trouble, etc., to improve the convenience of construction, improve the convenience of construction, and simplify the assembly process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

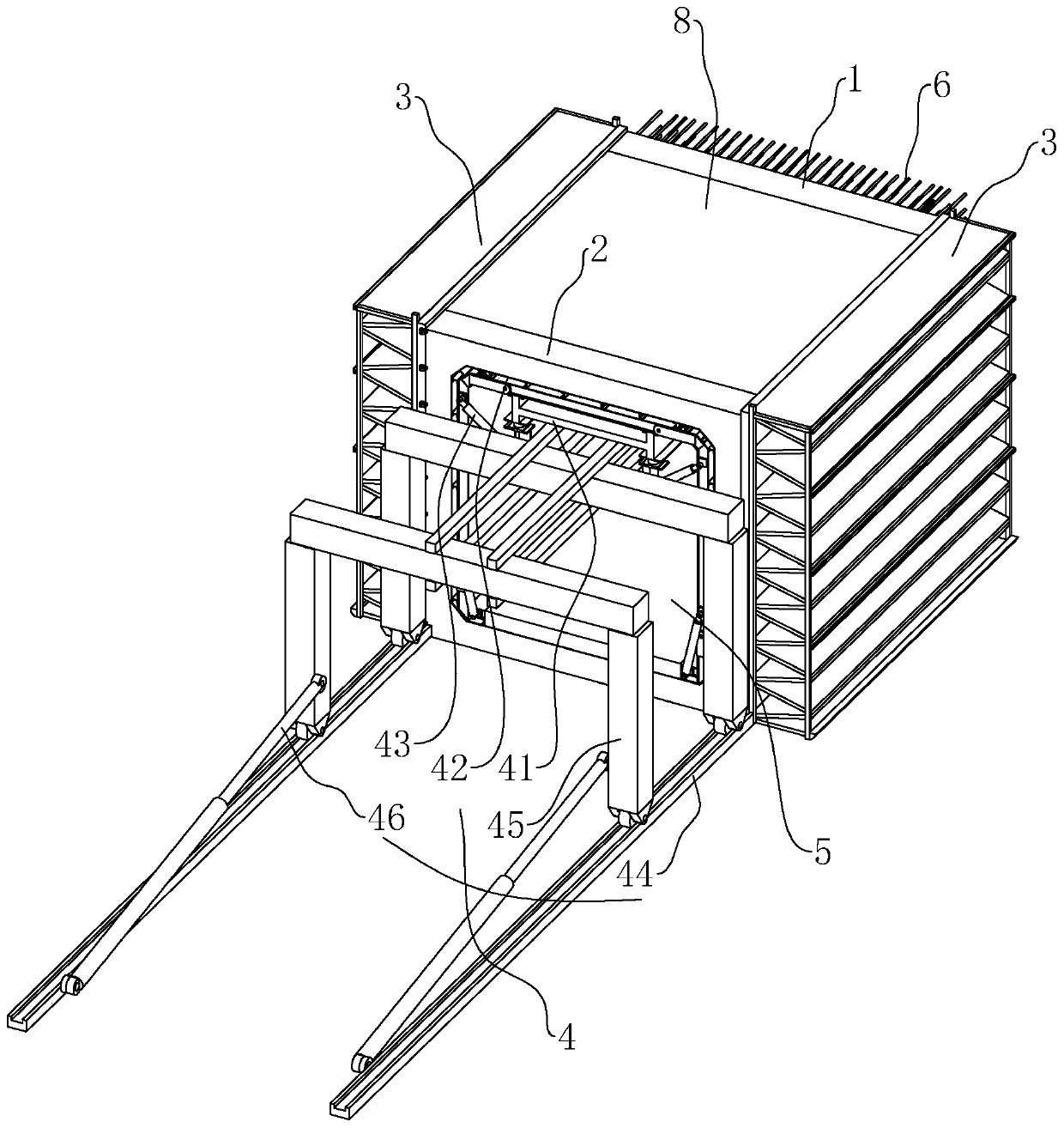

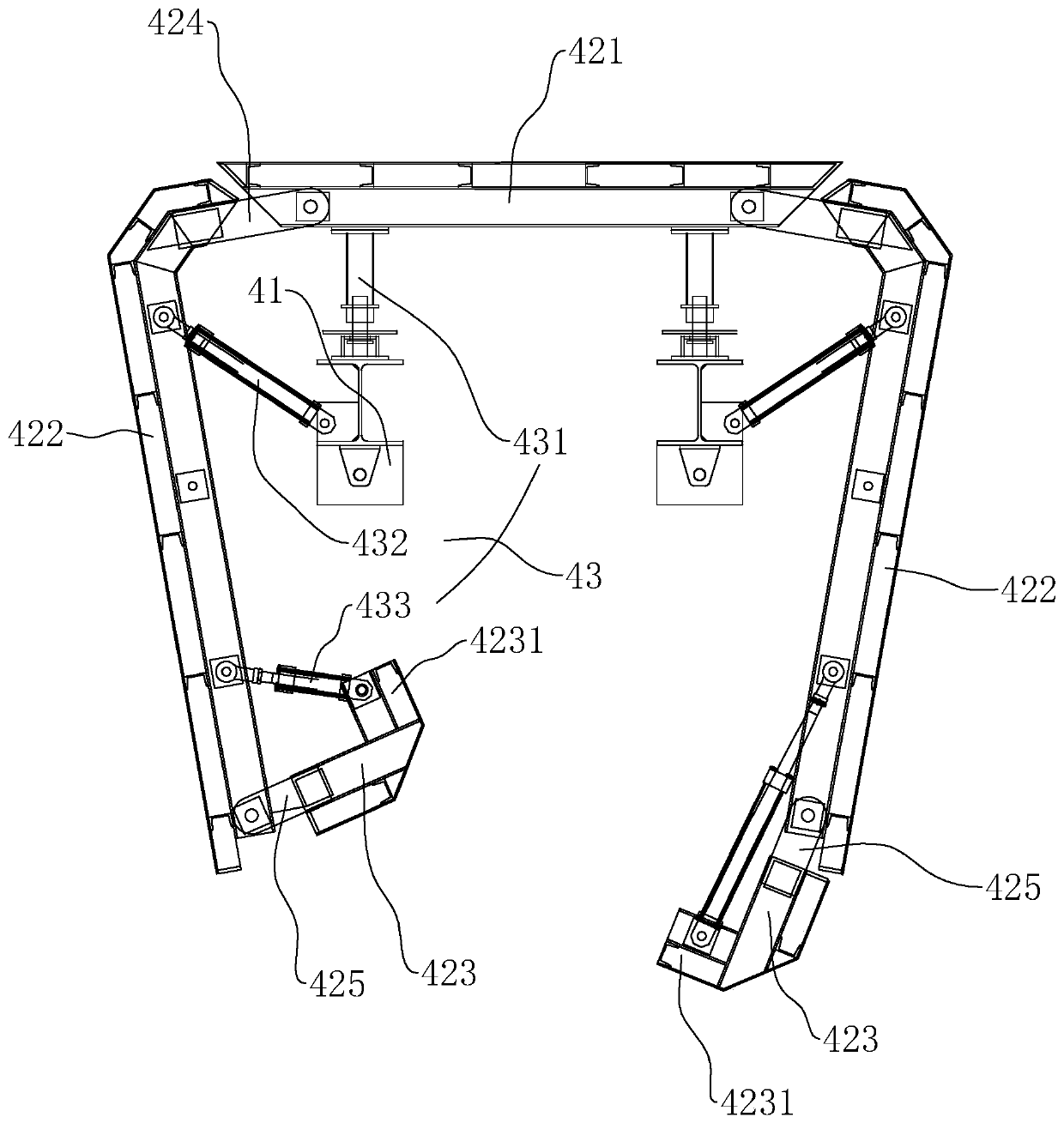

[0046] A pipe gallery prefabricated mold, such as figure 1 As shown, including fixed end mold 1, movable end mold 2, outer mold 3, inner mold 4 and bottom mold 5, movable end mold 2 and fixed end mold 1 are arranged at the two ends of outer mold 3 respectively, and movable end mold 2 It is hingedly arranged with the outer mold 3. When it is in the mold loading state, the inner mold 4 is combined with the bottom mold 5 to form a tubular inner mold 4 and is arranged in the outer mold 3, so that the inner mold 4 and the bottom mold 5 are combined. A molding space is formed between the outer molds 3 .

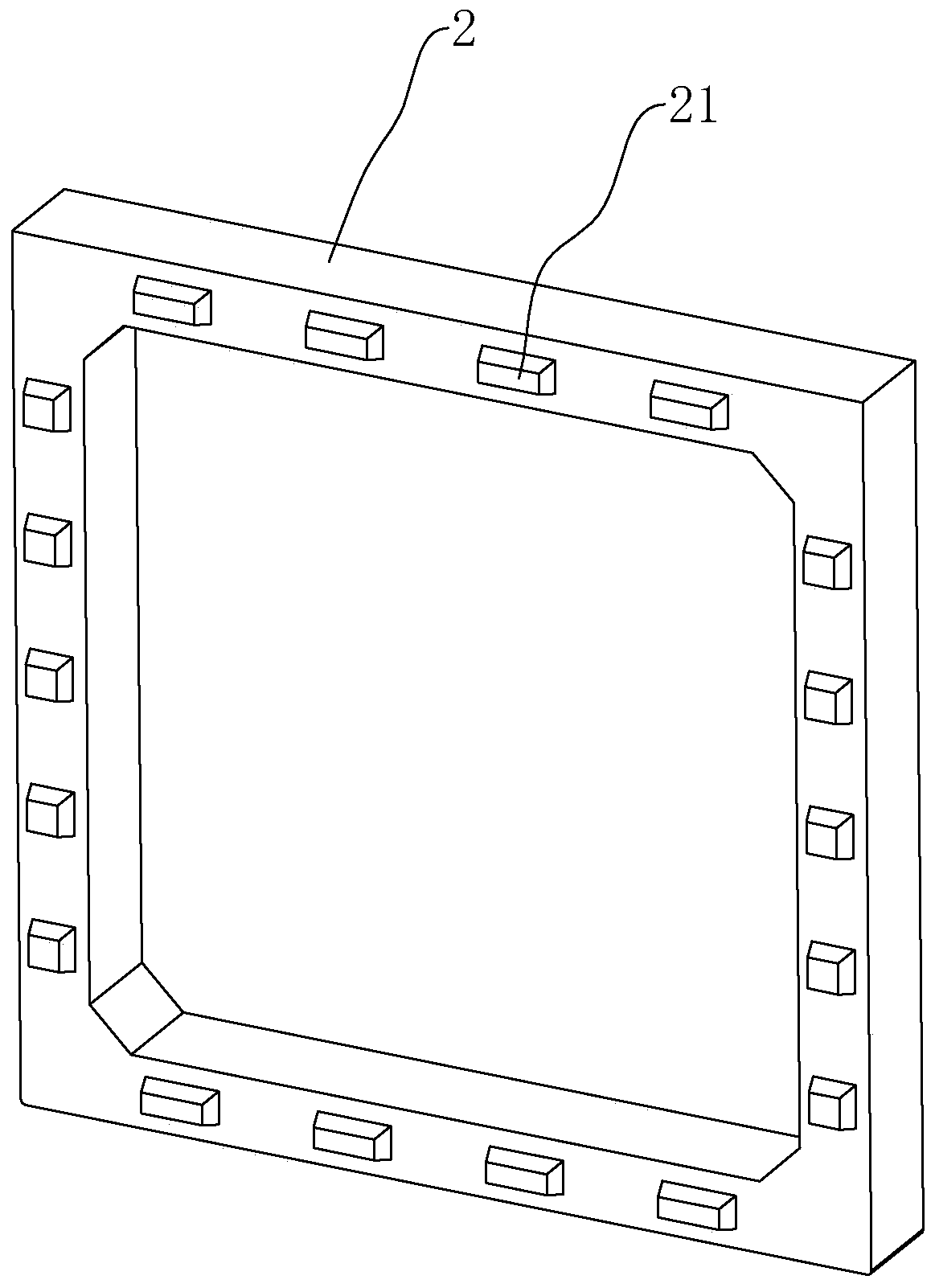

[0047] Such as figure 1 and figure 2 As shown, the corners at the bottom of the outer mold 3 are set as arc angles, so that the bottom of the outer mold 3 is smooth and has no edges and corners, and the handling process is not easy to be damaged, and it is more beautiful. One side of the movable end mold 2 is hinged to one side of the outer mold 3, and the other side is fastene...

Embodiment 2

[0054] A method of pipe gallery construction, such as Figure 1 to Figure 4 As shown, the construction of the pipe gallery prefabricated mold in the first embodiment includes the following steps:

[0055] S1. Prepare the prefabricated mold of the pipe gallery and clean it;

[0056] S2. Insert steel bars 6 into each reinforcement hole 11 of the fixed end mold 1, and reserve a section outside the fixed end mold 1;

[0057] S3, set the rubber plug 13 on the steel bar 6, and insert it into the steel bar hole 11, and then bind the steel bar skeleton for forming the pipe gallery 8 on the steel bar 6 located inside the fixed end mold 1;

[0058] S4. Insert the water-stop steel plate 7 into the reserved notch 12 of the fixed end mold 1, and insert a hollow rubber strip 14 into the reserved notch 12 to fix the water-stop steel plate 7;

[0059] S5, fixing the fixed end mold 1 with the reinforcement skeleton and the outer mold 3, and opening the movable end mold 2 to wait for the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com