Acrylic polyurethane finish for rail traffic vehicle interiors and preparation method thereof

An acrylic polyurethane and rail transit vehicle technology, which is applied in the field of acrylic polyurethane topcoat for rail transit vehicle interiors and its preparation, can solve the problems of less all requirements and the like, and achieves improved bending resistance, low content, and irritating odor. and odorless effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

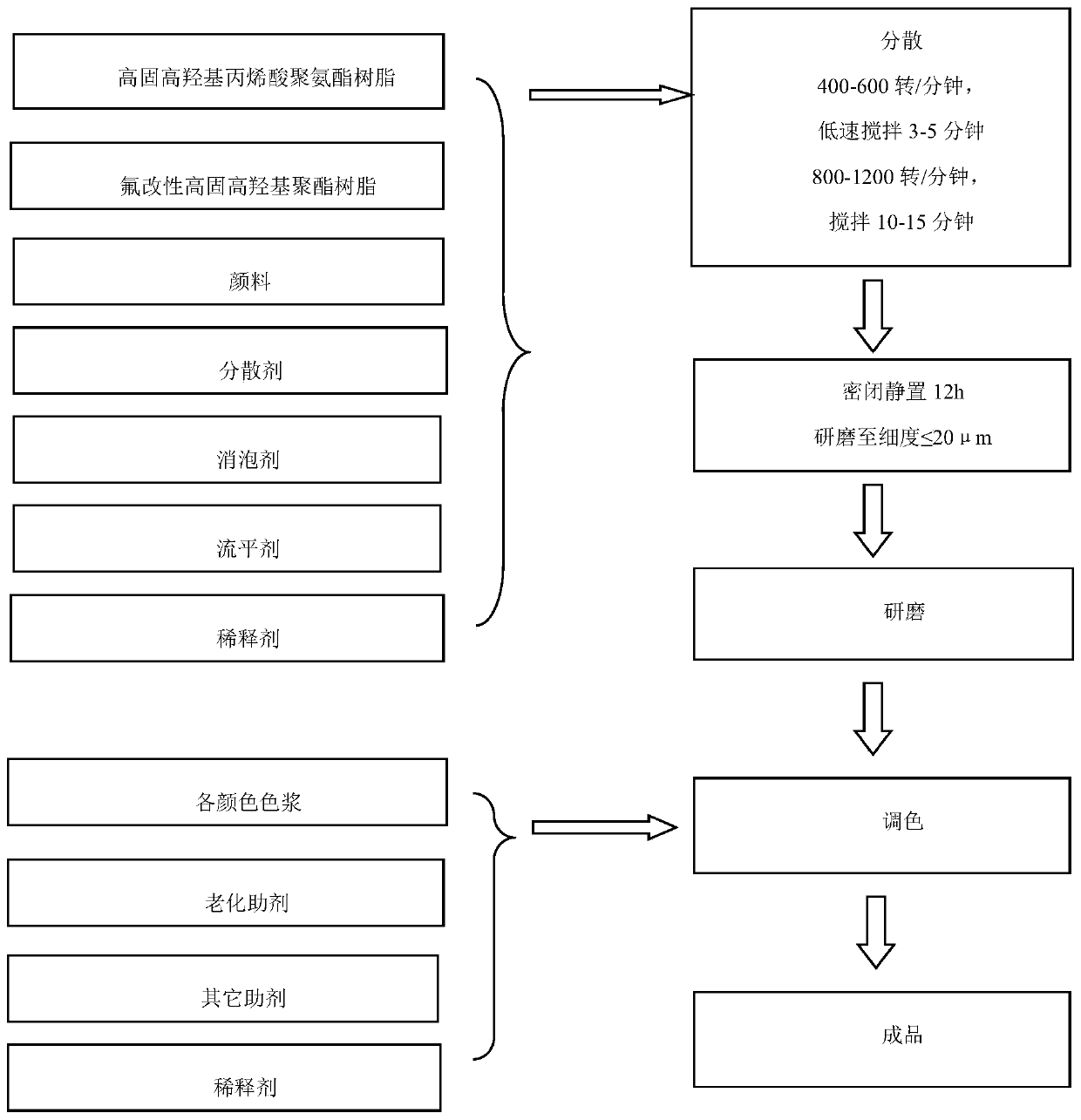

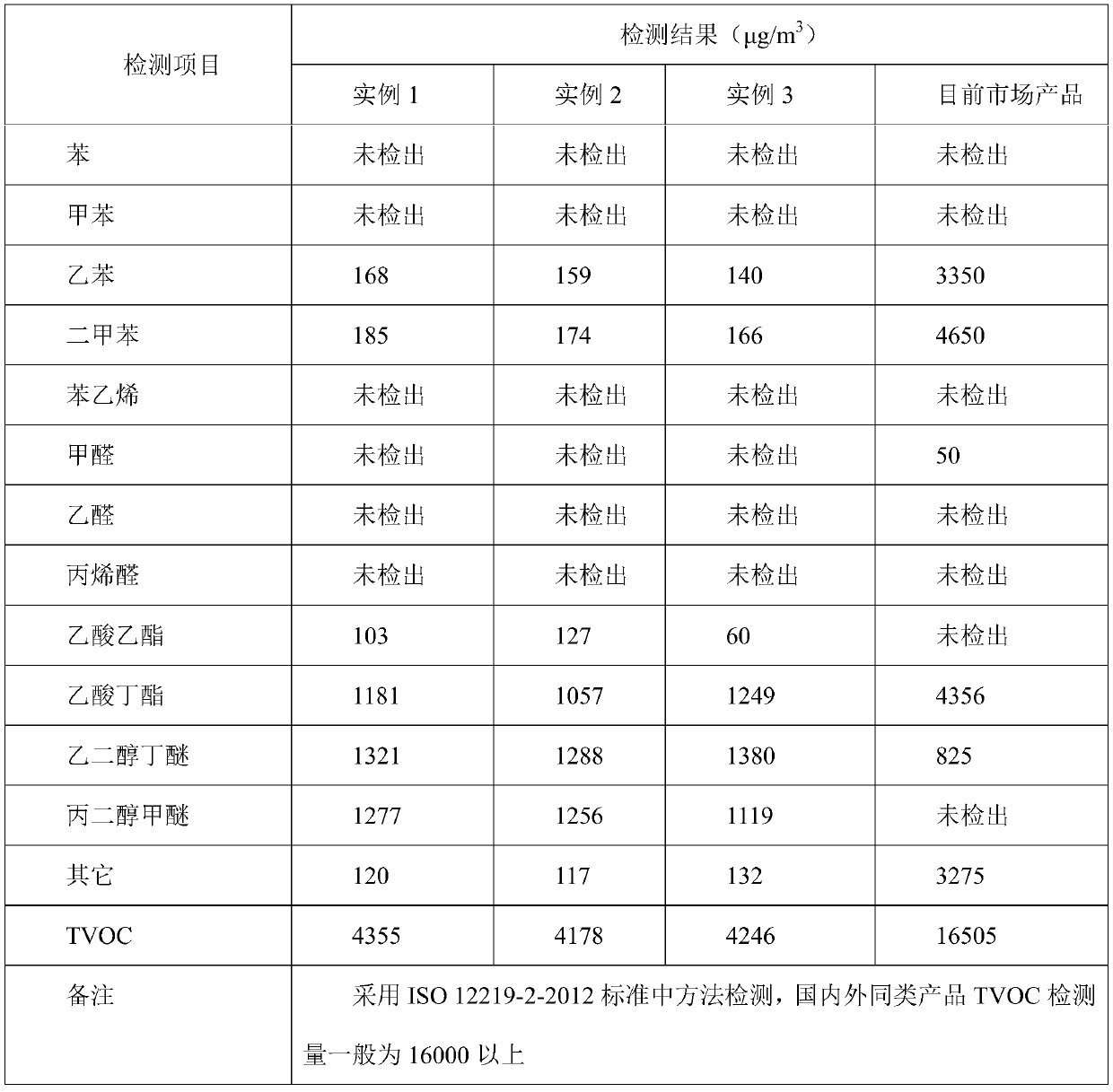

[0063] An acrylic polyurethane topcoat for interior decoration of rail transit vehicles and a preparation method thereof, comprising two parts of a paint material and a curing agent, and said polyurethane paint comprises the following raw materials in parts by weight:

[0064] (1) Paint components include: 30 parts of high-solid high-hydroxyl acrylic polyurethane resin, 25 parts of fluorine-modified high-solid high-hydroxyl polyester resin, 1.5 parts of solvent-free anti-graffiti reactive silicone leveling agent, solvent-free 0.8 parts of silicone defoamer, 1.5 parts of solvent-free low molecular weight wetting and dispersing agent, 2 parts of solvent-free anti-aging additive, 0.5 parts of solvent-free leveling agent, 22.7 parts of pigment, 6 parts of matte powder, poly 1 part of amide wax, 9 parts of diluent;

[0065] (2) The curing agent components include:

[0066] 60 parts of solvent-free aliphatic polyisocyanate trimer, 1 part of polyurethane dehydrating agent, 10 parts ...

Embodiment 2

[0074] An acrylic polyurethane topcoat for interior decoration of rail transit vehicles and a preparation method thereof, comprising two parts of a paint material and a curing agent, and said polyurethane paint comprises the following raw materials in parts by weight:

[0075] (1) Paint components include: 35 parts of high-solid high-hydroxyl acrylic polyurethane resin, 17.5 parts of fluorine-modified high-solid high-hydroxyl polyester resin, 1 part of solvent-free anti-graffiti reactive silicone leveling agent, solvent-free 0.5 parts of silicone defoamer, 1 part of solvent-free low molecular weight wetting and dispersing agent, 3 parts of solvent-free anti-aging additive, 0.3 parts of solvent-free leveling agent, 24.7 parts of pigment, 4.5 parts of matte powder, poly 1.5 parts of amide wax, 11 parts of diluent;

[0076] (2) The curing agent components include:

[0077] 60 parts of solvent-free aliphatic polyisocyanate trimer, 1.2 parts of polyurethane dehydrating agent, 10 p...

Embodiment 3

[0082] An acrylic polyurethane topcoat for interior decoration of rail transit vehicles and a preparation method thereof, comprising two parts of a paint material and a curing agent, and said polyurethane paint comprises the following raw materials in parts by weight:

[0083] (1) Paint components include: 40 parts of high-solid and high-hydroxyl acrylic polyurethane resin, 13.3 parts of fluorine-modified high-solid and high-hydroxyl polyester resin, 2 parts of solvent-free anti-graffiti reactive silicone leveling agent, solvent-free 1 part of silicone defoamer, 1.3 parts of solvent-free low molecular weight wetting and dispersing agent, 2.5 parts of solvent-free anti-aging additive, 0.4 part of solvent-free leveling agent, 16.5 parts of pigment, 5 parts of matte powder, poly 1 part of amide wax, 17 parts of diluent;

[0084] (2) The curing agent components include:

[0085] 60 parts of solvent-free aliphatic polyisocyanate trimer, 1.5 parts of polyurethane dehydrating agent,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com