Ripening method for reducing rate of rotten fruits in latter stage of ripening of mangifera indica L.

A mango and ripening technology, which is applied in the preservation of fruits and vegetables, the preservation of food ingredients as anti-microbials, and the preservation of food, can solve the problem of high rotten fruit rate, and achieve the reduction of rotten fruit rate, high fruit commodity rate, and accelerated ripening rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

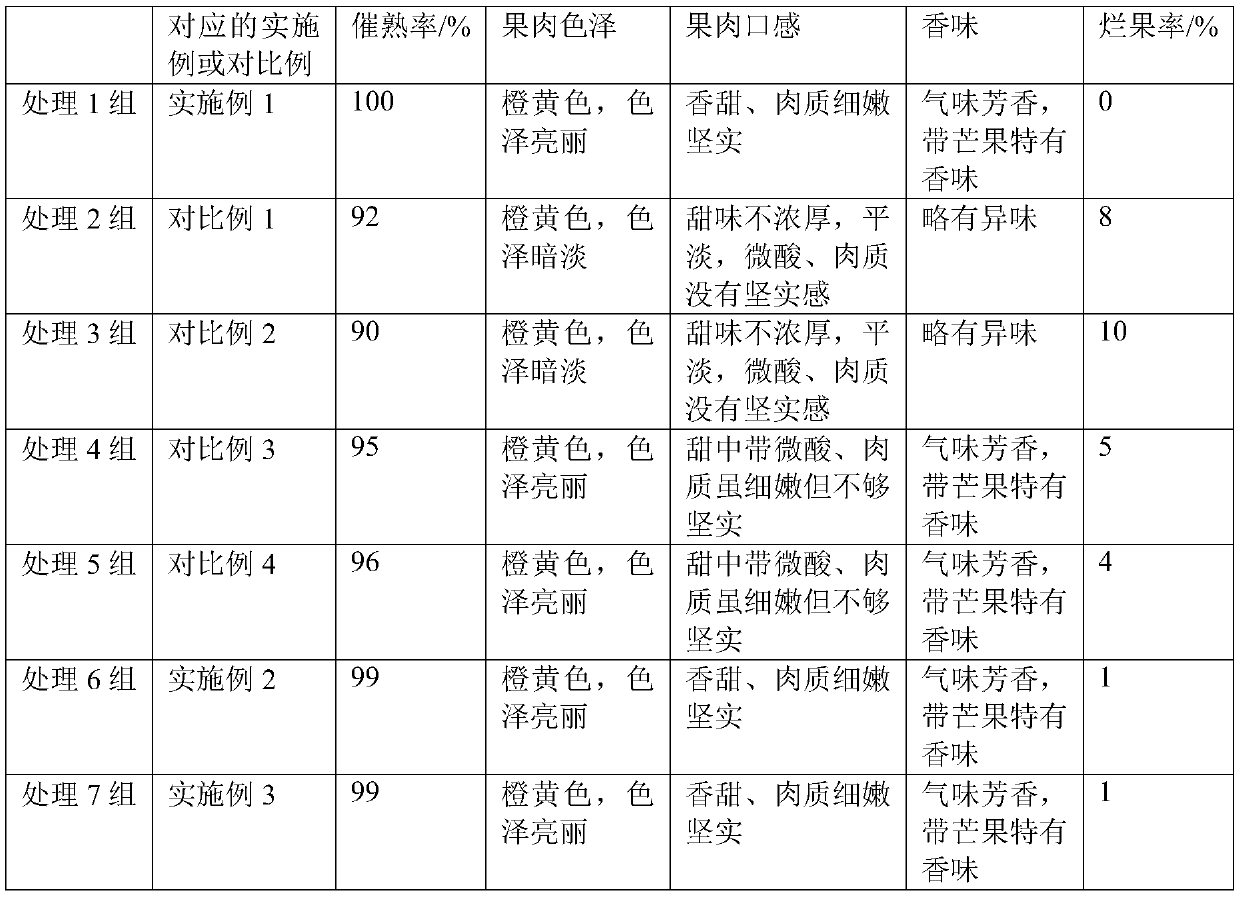

Examples

Embodiment 1

[0015] 1) Collect the mangoes harvested in the physiological maturity stage for subsequent use;

[0016] 2) Soak the mango collected in step 1) in the naphthalene acetic acid solution, take it out when the mango fruit surface is completely submerged below the naphthalene acetic acid solution level, and let it dry naturally until the fruit surface is dry, then put it in a carton, and use a Layers of straw (the thickness of the straw layer is 2cm) are stacked at intervals in the form of a layer of mango, wherein the bottom layer and the top layer are both straw layers. After the stacking is completed, the carton is sealed and placed under indoor conditions of 25 °C for 35 hours as the ripening of the mangoes; among them,

[0017] Described naphthalene acetic acid solution is formulated by naphthalene acetic acid, fatty alcohol polyoxyethylene ether and distilled water, and the concentration of described naphthalene acetic acid in naphthalene acetic acid solution is 18ppm, and the...

Embodiment 2

[0029] 1) Collect the mangoes harvested in the physiological maturity stage for subsequent use;

[0030] 2) Soak the mango collected in step 1) in the naphthalene acetic acid solution, take it out when the mango fruit surface is completely submerged below the naphthalene acetic acid solution level, and let it dry naturally until the fruit surface is dry, then put it in a carton, and use a Layers of straw (the thickness of the straw layer is 1cm) are stacked at intervals in the form of a layer of mango, wherein the bottom and top layers are both straw layers. After the stacking is completed, the carton is sealed and placed at 22°C for 48 hours as a ripening of the mango; among them,

[0031] Described naphthalene acetic acid solution is formulated by naphthalene acetic acid, fatty alcohol polyoxyethylene ether and distilled water, and the concentration of described naphthalene acetic acid in naphthalene acetic acid solution is 15ppm, and the concentration of fatty alcohol polyox...

Embodiment 3

[0033] 1) Collect the mangoes harvested in the physiological maturity stage for subsequent use;

[0034] 2) Soak the mango collected in step 1) in the naphthalene acetic acid solution, take it out when the mango fruit surface is completely submerged below the naphthalene acetic acid solution level, and let it dry naturally until the fruit surface is dry, then put it in a carton, and use a Layers of straw (the thickness of the straw layer is 2cm) are stacked at intervals in the form of a layer of mango, wherein the bottom and top layers are both straw layers. After the stacking is completed, the carton is sealed and placed under indoor conditions of 25°C for 24 hours as the ripening of the mango; among them,

[0035] Described naphthalene acetic acid solution is formulated by naphthalene acetic acid, fatty alcohol polyoxyethylene ether and distilled water, and the concentration of described naphthalene acetic acid in naphthalene acetic acid solution is 20ppm, and the concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com