A kind of citrus moisture control dechlorotic method

A wet chlorotic and citrus technology, applied in the field of fruit ripening, can solve the problems of unsatisfactory color change of skin, uneven chlorosis, and blackened fruit stalk, and achieve ideal color change, uniform chlorosis, and fresh fruit stalk. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

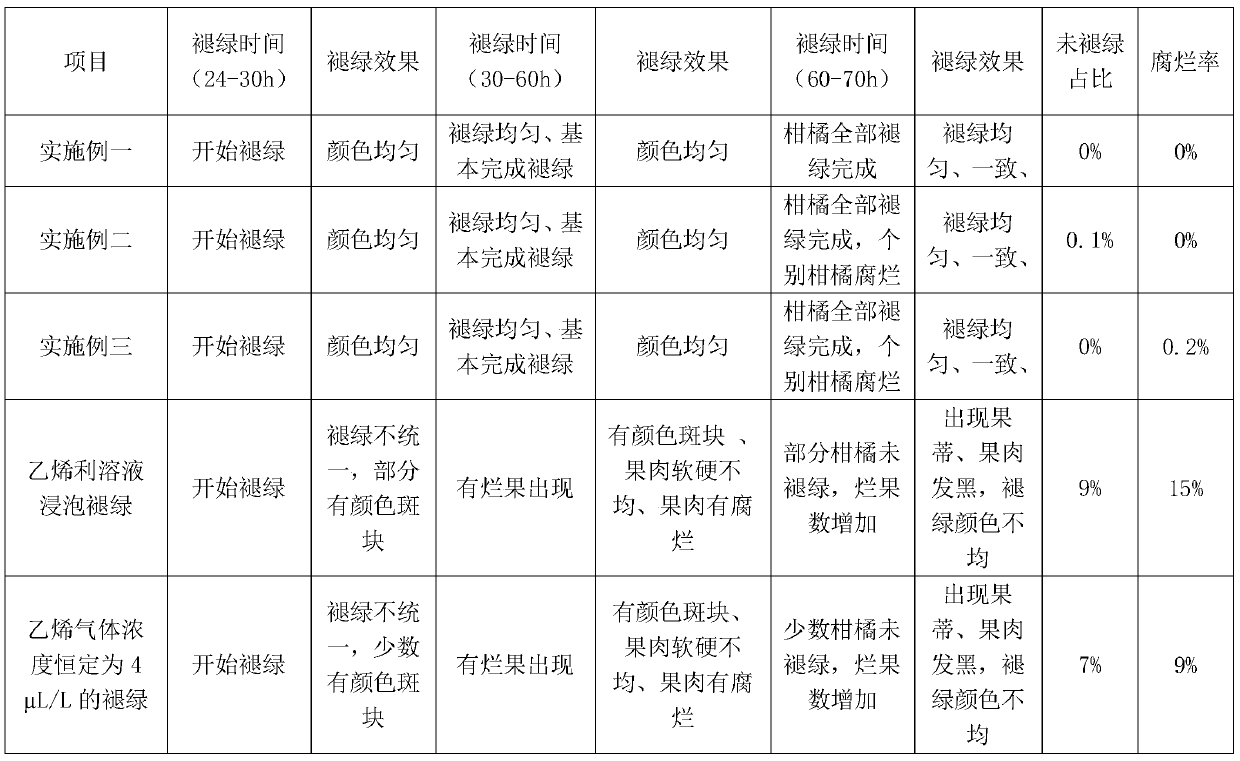

Examples

Embodiment 1

[0019] A method for moisture-controlling dechlorosis of citrus, the method may further comprise the steps:

[0020] a. Storage chlorosis treatment: Put citrus with mature pulp and green peel into the chlorosis storage and add ethylene for chlorosis treatment. The ethylene concentration is 6 μL / L, and the flow rate is 12.5 mL / min to control chlorosis The storage temperature is 25°C, the relative humidity is 95%, and the treatment time is 29 hours. During the treatment process, an air circulation fan is used for air circulation treatment. The volume fraction of carbon dioxide in the green pool is <3%;

[0021] b. Medium-term chlorosis treatment: After the chlorosis treatment in the storage is completed, the concentration of ethylene is controlled to 4 μL / L, the inflow flow rate is 6.5mL / min, and the temperature of the chlorosis storage is controlled at 26°C and the relative humidity is 96%. The treatment is 30h And carry out air circulation treatment, the air circulation treatm...

Embodiment 2

[0024] A method for moisture-controlling dechlorosis of citrus, the method may further comprise the steps:

[0025] a. Storage chlorosis treatment: Put the citrus with mature pulp and green peel into the chlorosis storage and add ethylene for chlorosis treatment. The ethylene concentration is 5 μL / L, and the flow rate is 10 mL / min to control the chlorosis storage. The temperature is 22°C, the relative humidity is 95%, and the treatment time is 26 hours. During the treatment process, an air circulation fan is used for air circulation treatment. The air circulation treatment is once every 3 minutes, and the air replacement cycle is once every 1 hour to control chlorosis The volume fraction of carbon dioxide in the pool is <3%;

[0026] b. Medium-term chlorosis treatment: After the chlorosis treatment in the storage is completed, the concentration of ethylene is controlled to 3 μL / L, the flow rate is 4mL / min, and the temperature of the chlorosis storage is controlled at 24°C and ...

Embodiment 3

[0029] A method for moisture-controlling dechlorosis of citrus, the method may further comprise the steps:

[0030] a. Storage chlorosis treatment: Put the citrus whose flesh is mature and the peel is still green into the chlorosis storage and add ethylene for chlorosis treatment. The ethylene concentration is 7μL / L and the flow rate is 15mL / min to control the chlorosis storage. The temperature is 28°C, the relative humidity is 95%, and the treatment time is 32 hours. During the treatment process, an air circulation fan is used for air circulation treatment. The air circulation treatment is once every 5 minutes, and the air replacement cycle is once every 1 hour to control chlorosis The volume fraction of carbon dioxide in the pool is <3%;

[0031] b. Medium-term chlorosis treatment: After the chlorosis treatment in the warehouse is completed, the concentration of ethylene is controlled to 5 μL / L, the flow rate is 9mL / min, and the temperature of the chlorosis warehouse is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com