Method for reducing circuit losses based on single crystal copper

A high-frequency circuit and single-crystal copper technology, which is applied in the field of reducing high-frequency circuit loss based on single-crystal copper, can solve the problems of high-frequency transmission loss, high price, and high conductivity, and achieve low energy loss and reduce The effect of mass and volume, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

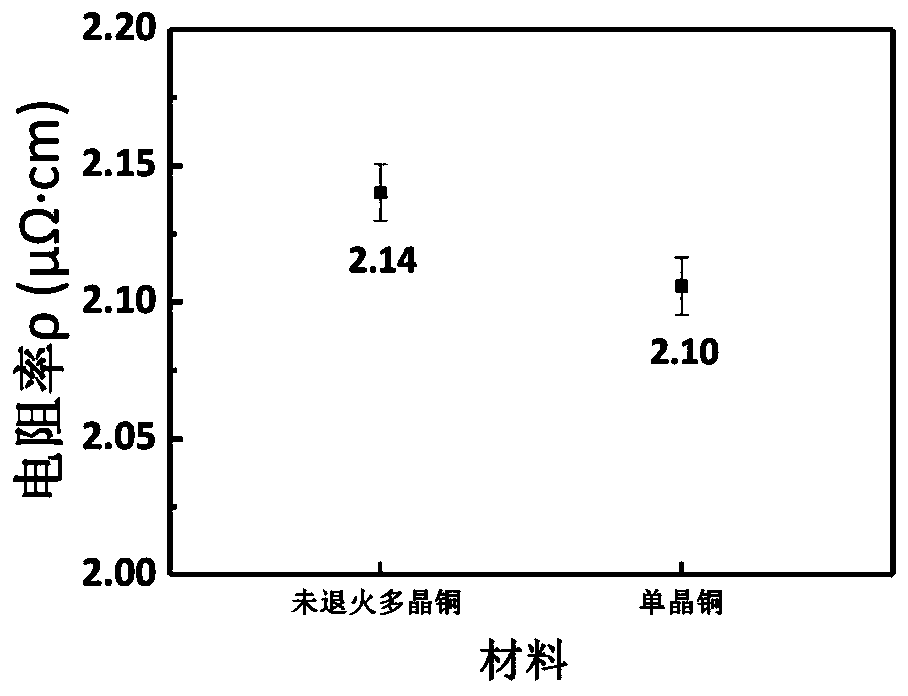

[0014] With the gradual popularization of smart phones, and due to the innovation of hardware technology, the configuration of smart phones is getting higher and higher, the CPU has developed from single-core to quad-core, and the frequency is getting higher and higher, and the software occupies more and more memory. Mobile phones are becoming thinner and thinner in pursuit of aesthetics, resulting in increasing heat generated by mobile phones. Therefore, it is very necessary to reduce the energy consumption of the mobile phone. At present, most of the integrated circuits in mobile phones use copper foil made of hot pressing or electroplating as the circuit layer of the integrated circuit. Using the conductive properties of single crystal copper superior to polycrystalline copper, single crystal copper can be used as a conductive layer in integrated circuit chips , thereby reducing the energy loss of the mobile phone.

Embodiment 2

[0016] High-frequency lines and cables place extremely high demands on the properties of conductive materials. It is better than that there are a large number of grain boundaries and defects in polycrystalline copper, which cause huge signal loss when transmitting high-frequency signals. Therefore, the current high-end high-frequency signal lines and cables mostly use silver and other precious metals as conductive materials. Taking advantage of the advantages of no grain boundaries, almost no defects, and high surface flatness in single crystal copper, single crystal copper can be used to make high-frequency signal lines and cables. Compared with high-frequency signal cables made of polycrystalline copper, single-crystal copper high-frequency cables have lower signal loss; compared with high-frequency signal cables made of silver, single-crystal copper high-frequency cables have lower production cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com