Exhaust waste heat recovery type energy-saving device

An energy-saving device and waste heat recovery technology, which can be used in ventilation and heating energy recovery systems, space heating and ventilation details, and household heating, etc. problems, to achieve the effect of reducing heat transfer, reducing cooling/heating load, and increasing average radiant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

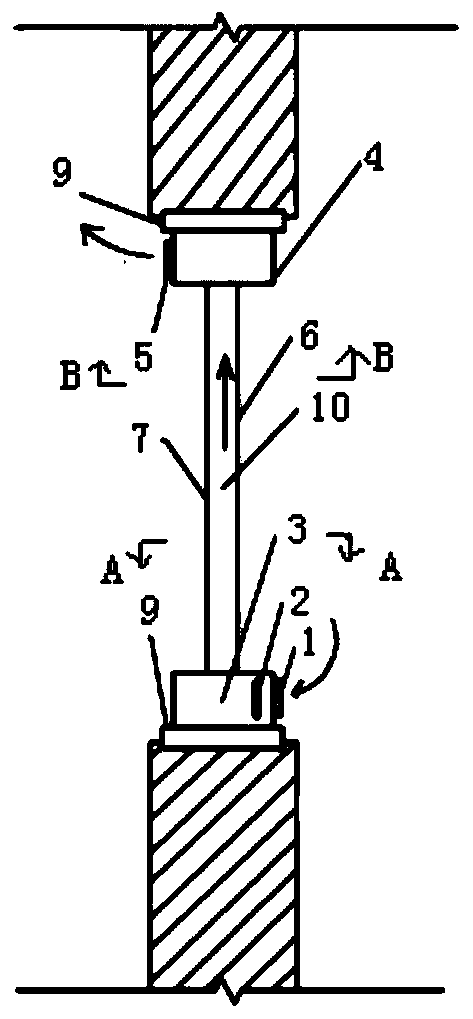

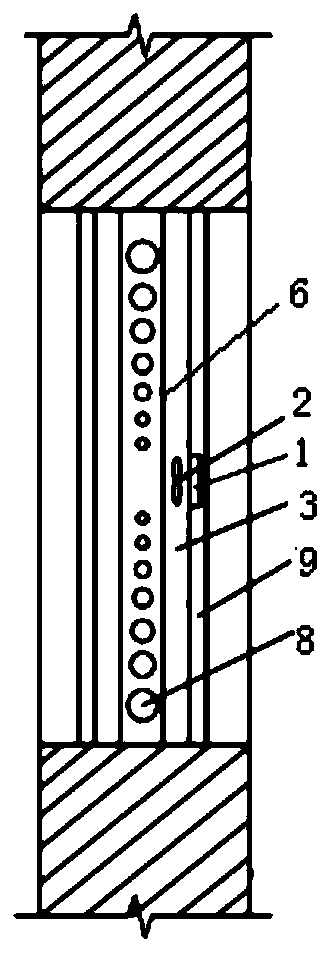

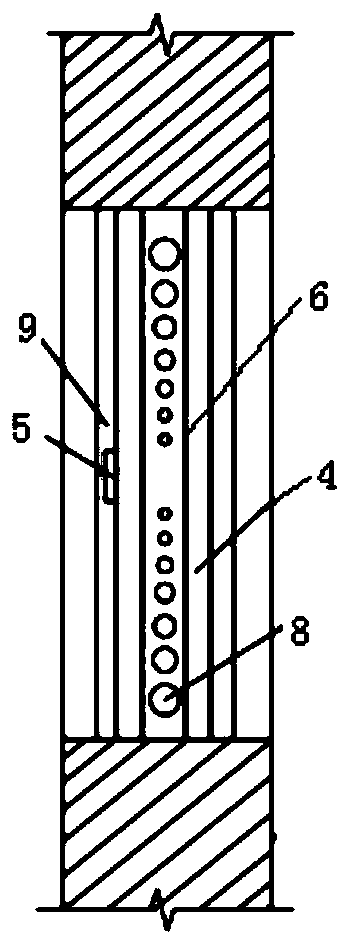

[0017] refer to figure 1 , figure 2 and image 3 , an exhaust waste heat recovery type energy-saving device of the present invention, comprising an exhaust inlet 1, an exhaust fan 2, an exhaust lower header 3, an exhaust upper header 4, an exhaust outlet 5, an inner layer body 6, and an outer layer body 7 and several header openings 8, an inner layer body 6 and an outer layer body 7 are arranged between the exhaust lower header 3 and the upper exhaust header 4, and an inner layer body 6 and an outer layer body 7 remain between the inner layer body 6 and the outer layer body 7 There are gaps 10, the lower side wall of the exhaust lower header 3 and the upper side wall of the exhaust upper header 4 are provided with several header holes 8, the exhaust lower header 3 and the exhaust upper header 4 are all communicated with the gap 10 through the header hole 8, the rear side wall of the exhaust lower header 3 is provided with an exhaust inlet 1, and the exhaust fan 2 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com