Locking belt for producing dibenzoyl methane

A technology of dibenzoylmethane and locking bands, which is applied in the direction of pipes/pipe joints/fittings, hose connection devices, mechanical equipment, etc., can solve the problems of troublesome disassembly and low binding efficiency, and achieve improved connection firmness, Ease of operation and improved simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

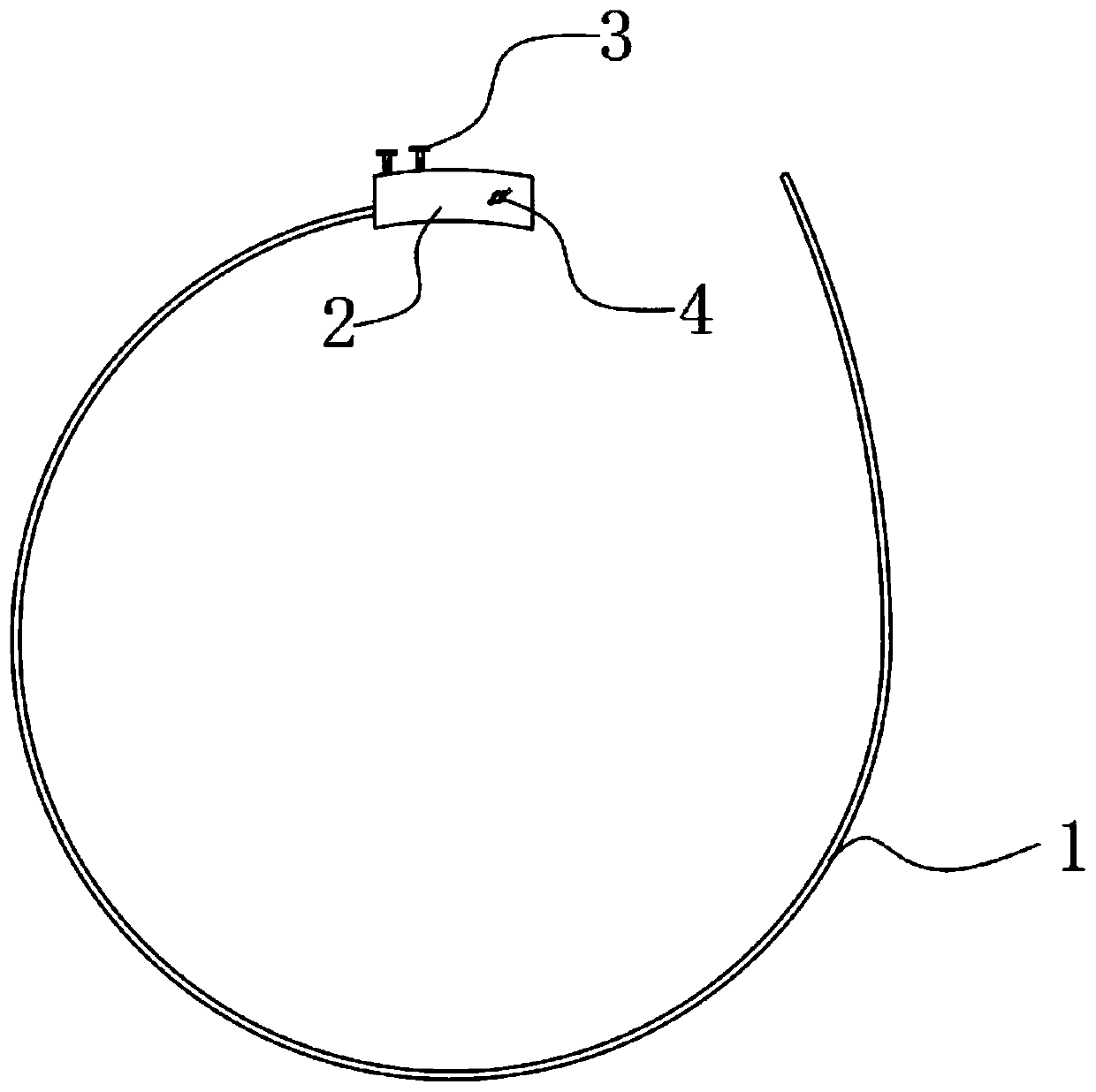

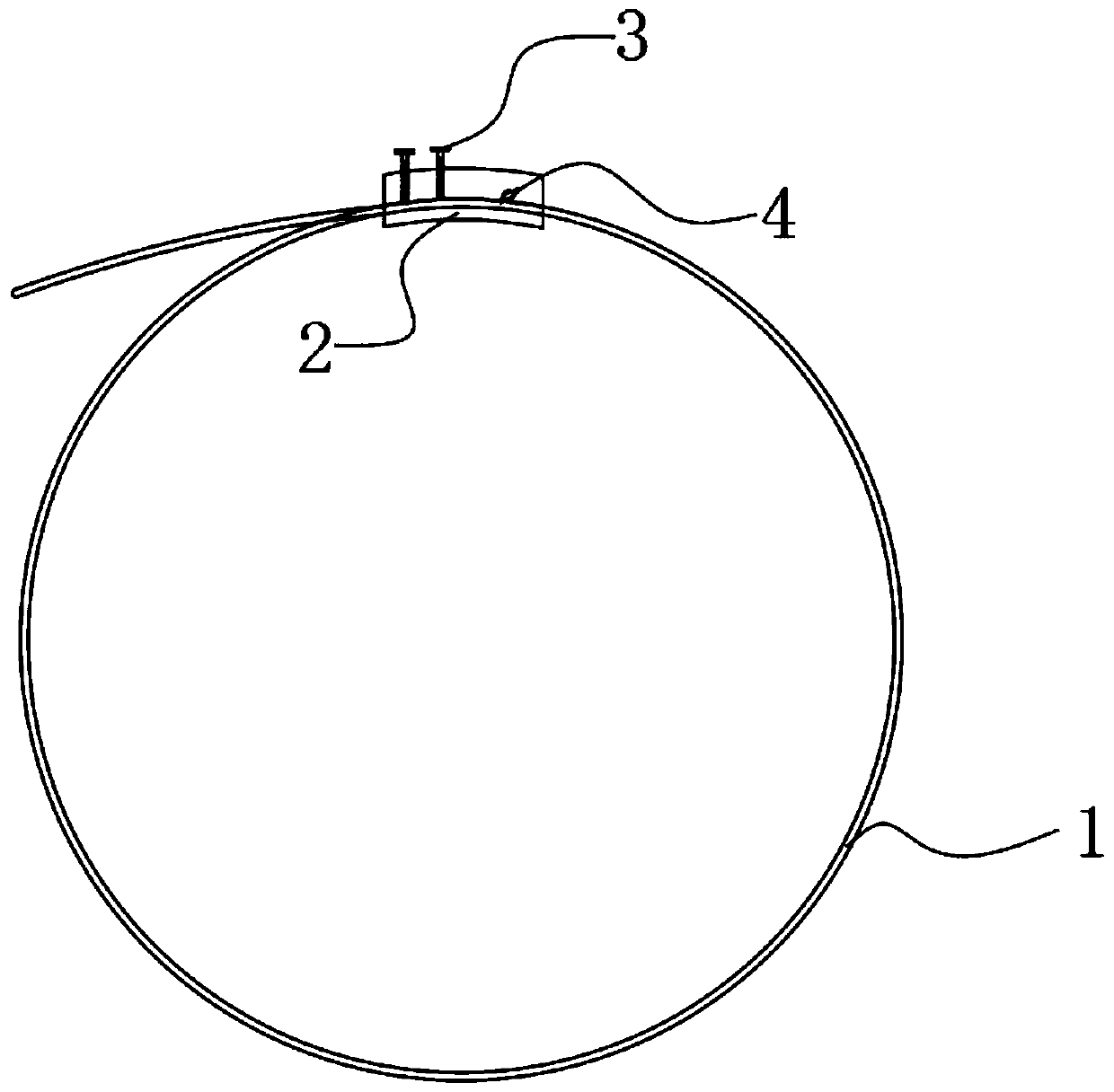

[0029] see figure 1 , figure 2 , Figure 7 As shown, it is a schematic diagram of the overall structure in an embodiment; including:

[0030] Locking belt 1, the main body of locking belt 1 is a strip-shaped square belt, and the outer wall of locking belt 1 is provided with engaging teeth-11, which is convenient for connection and improves the firmness of connection;

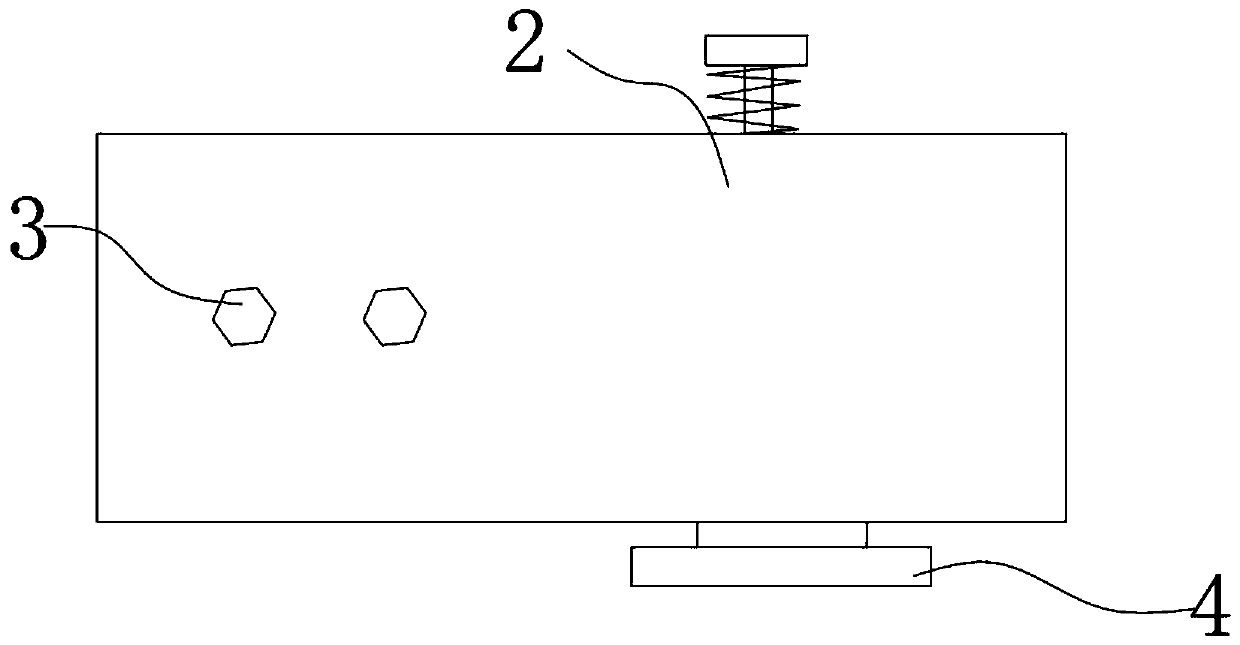

[0031] see Figure 4 As shown, the locking seat 2, the locking seat 2 includes a locking seat body 21, a mounting hole 23, and a belt hole 22, the mounting hole 23 is arranged inside the locking seat body 21, and the mounting hole 23 is set as a round hole , The bottom of the mounting hole 23 is provided with a threading hole 22, which facilitates the insertion of the locking strap from the threading hole 22. By installing the locking cylinder body 41 in the mounting hole 23, the ease of operation is improved.

[0032] see image 3 , locking screw 3, there are two locking screws 3, installed on the top of ...

Embodiment 2

[0037] Locking cylinder body 41 has handle 43, sinking groove 44, retaining seat 45, return spring 46, and one end of locking cylinder body 41 is provided with sinking groove 44, and the top of sinking groove 44 is provided with handle 43, and locking cylinder body 41 The other end is provided with retaining seat 45, and retaining seat 45 is arranged on the outside of locking seat 2, and the inwall of retaining seat 45 is provided with return spring 46, and the elastic force of return spring 46 can make locking cylinder body 41 return automatically, is conducive to The user operates to improve the firmness of the connection.

[0038] read on Figure 4 , Figure 5 and Figure 6 , The inner wall surface of the handle 43 is provided with a boss, the shape of the boss is a quadrangular column, and the boss and the handle 43 are arranged as an integrated structure.

[0039] see Figure 5 and Figure 6 , The side wall of the locking seat body 21 is provided with a square counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com