A reinforcement operating device for bridge maintenance

A technology of operating device and reinforcement device, applied in bridge maintenance, bridge reinforcement, bridge and other directions, can solve the problems of easy precipitation of grouting resin glue, easy cracks in bridge pillars, poor reinforcement effect, etc., to prevent precipitation and support effect. Good, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

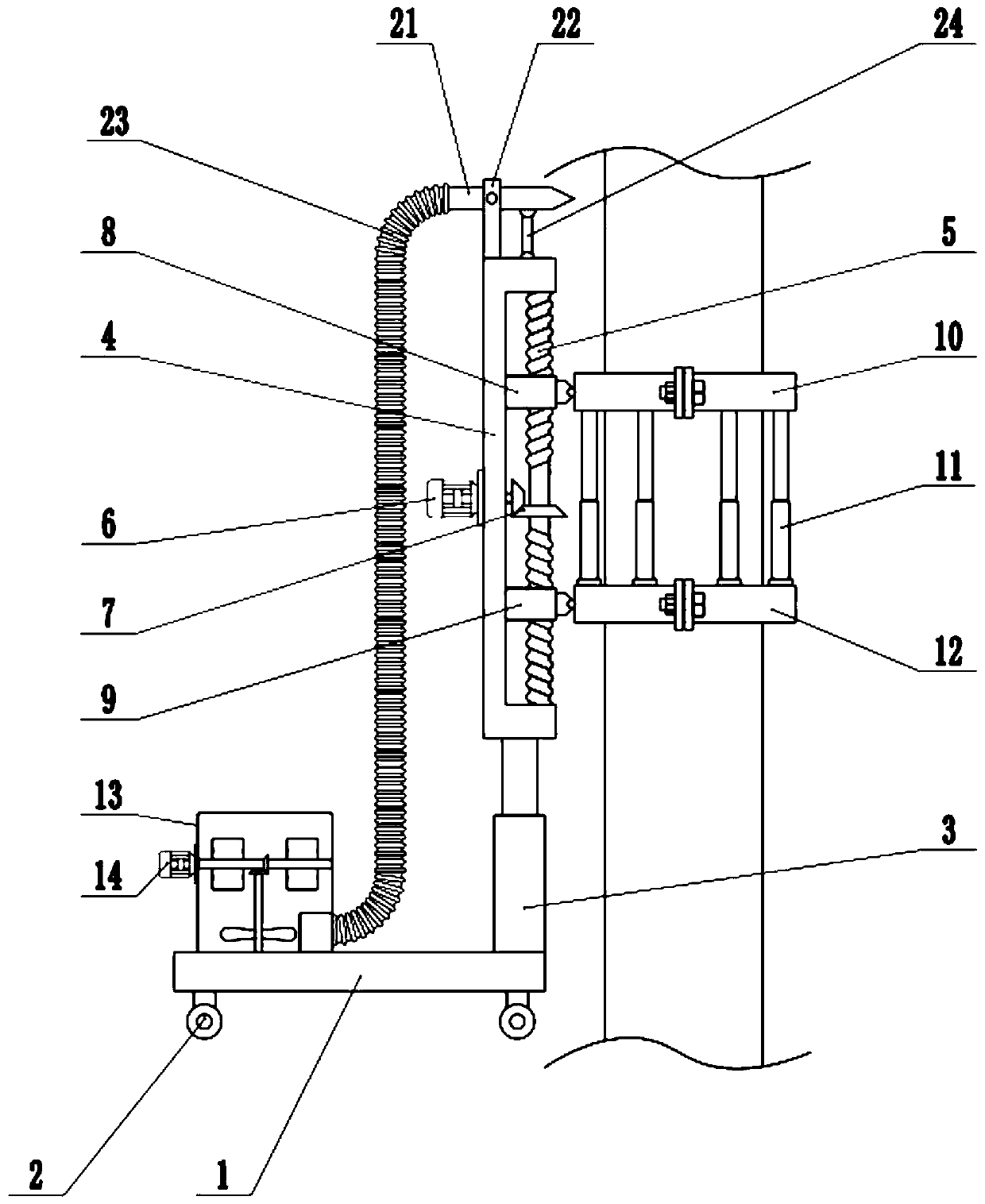

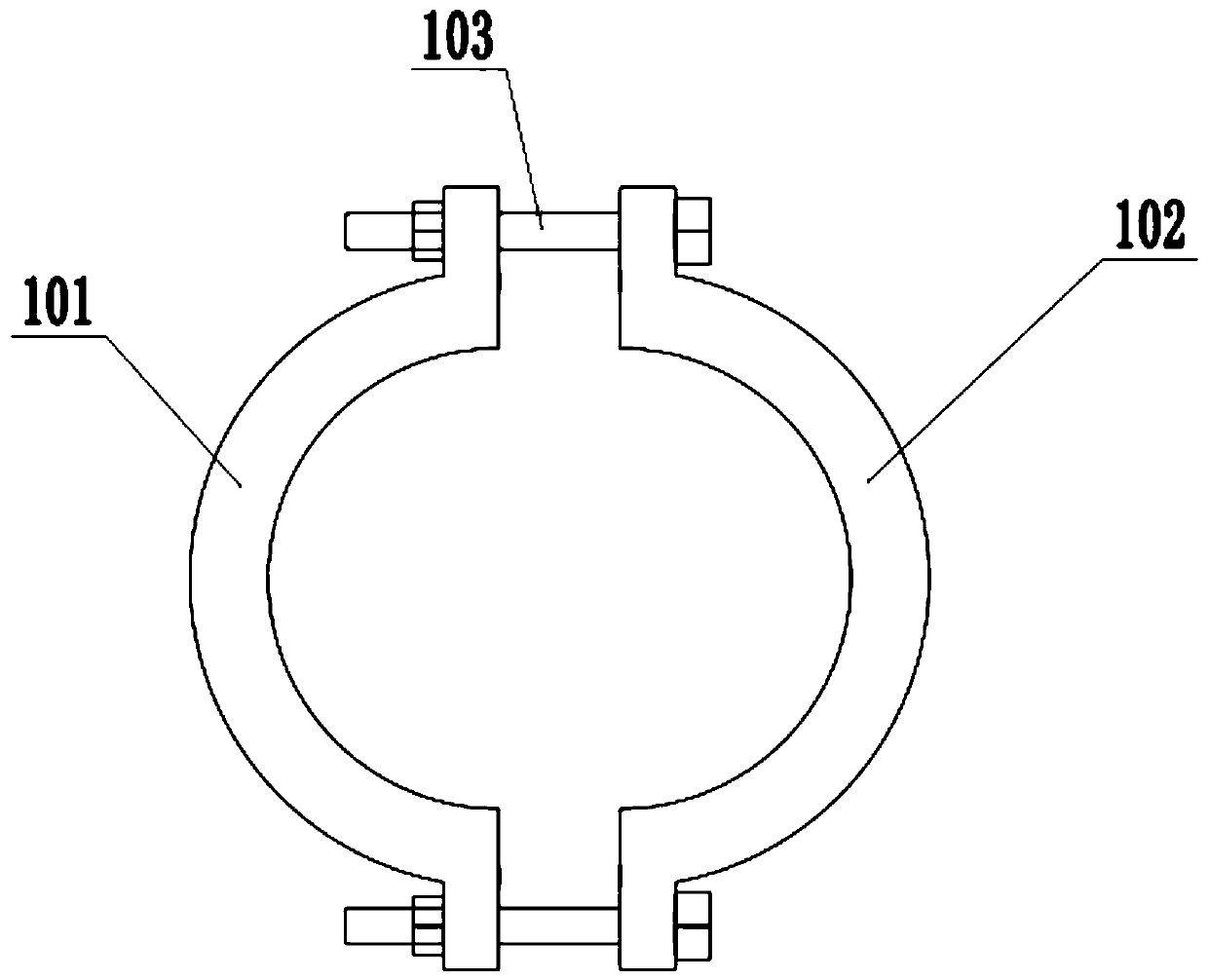

[0023] See Figure 1-4 In the embodiment of the present invention, a strengthening operation device for bridge maintenance includes a base 1, a first telescopic mechanism 3, and a lifting frame 4. A universal wheel 2 is installed on the lower surface of the base 1 to facilitate the movement of the device , The upper surface of the base 1 is fixedly connected with a first telescopic mechanism 3, the first telescopic mechanism 3 is an electro-hydraulic telescopic cylinder, and the top end of the first telescopic mechanism 3 is fixedly connected with a lifting frame 4 to control the first telescopic mechanism 3 to expand and contract. Drive the lifting frame 4 to move up and down, adjust the height of the lifting frame 4, the inside of the lifting frame 4 is provided with a two-way screw 5, the upper and lower ends of the two-way screw 5 are respectively connected to the lifting frame 4 in rotation, the two-way screw 5 is covered with The upper slider 8, the lower slider 9, the up...

Embodiment 2

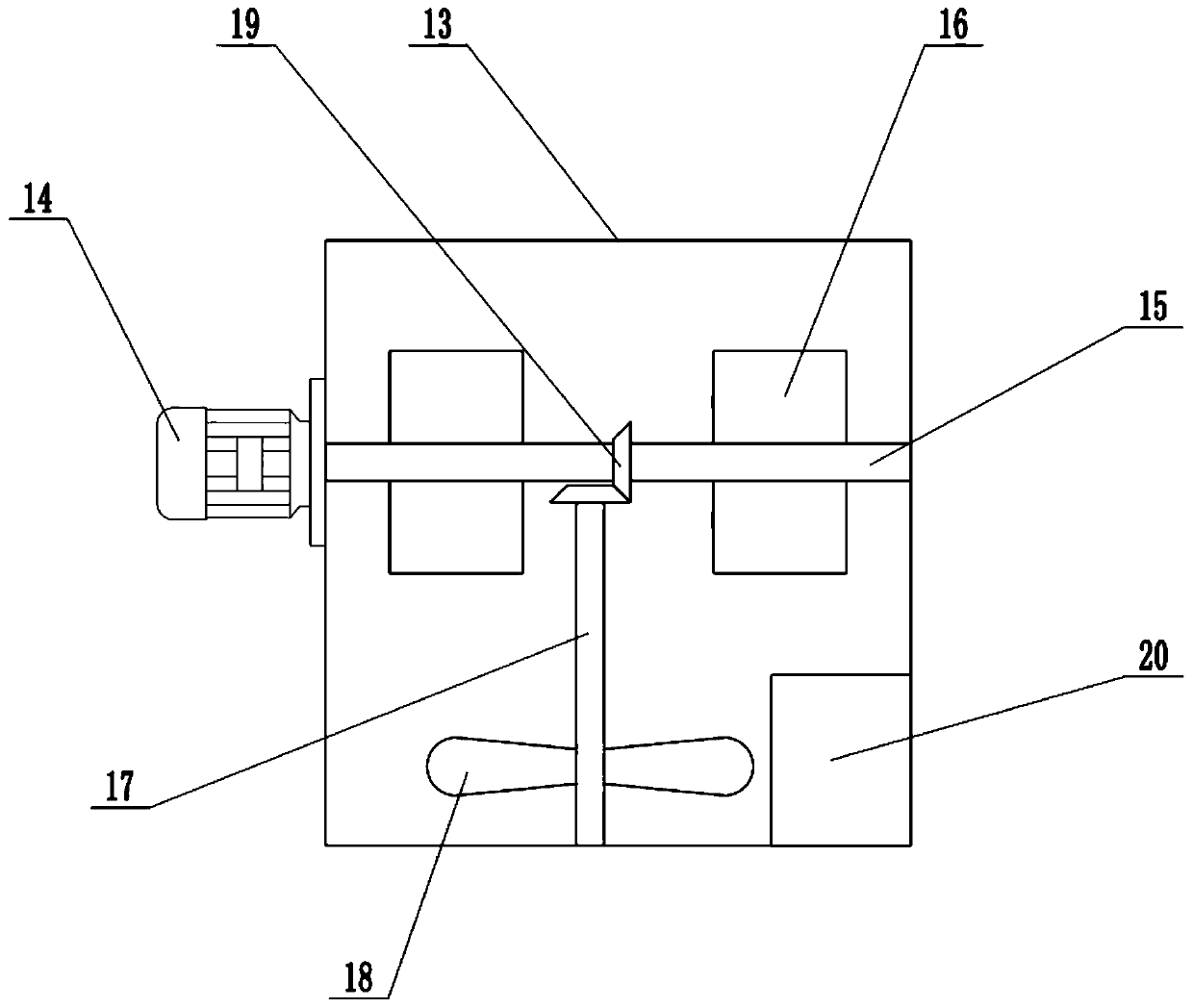

[0027] On the basis of embodiment 1, the inside of the injection box 13 is also provided with a driven shaft 17, which is rotatably connected to the bottom of the injection box 13, and the top end of the driven shaft 17 is connected to the driving shaft through the second gear set 19 The shaft 15 is connected, and the stirring blade 18 is distributed on the driven shaft 17. When the stirring motor 14 is running, the driving shaft 15 is driven to rotate, and then the driven shaft 17 is driven to rotate through the second gear set 19, thereby driving the stirring blade 18 to rotate. The leaf 18 agitates the grouting resin glue of the bottom layer to further prevent the grouting resin glue from depositing.

Embodiment 1、 Embodiment 2

[0028] Combining Embodiment 1 and Embodiment 2, the working principle of the present invention is: controlling the extension of the first telescopic mechanism 3, driving the lifting frame 4 to move upward, so that the lifting frame 4 is raised to the position to be repaired on the bridge pillar, and the upper reinforcement device 10 , The lower reinforcement device 12 is fixed on the bridge pillar, closely adheres to the bridge pillar, remains fixed, plays the role of strengthening the bridge pillar, controls the extension of the telescopic support rod 11, and the top end of the telescopic support rod 11 abuts the upper reinforcement device 10 , Use the telescopic support rod 11 to play the role of reinforcement and support, improve the stability of the bridge pillar, use the pump 20 to transport the grouting resin glue in the injection box 13 to the spray gun 21, spray it in the gap on the surface of the bridge pillar, to achieve repair The purpose of the gap is to start the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com