High-temperature purification method of zinc selenide raw material

A high-temperature purification and zinc selenide technology, applied in chemical instruments and methods, polycrystalline material growth, from condensed steam, etc., can solve the problems of zinc selenide content, deviation of stoichiometric ratio, etc., and achieve the effect of optimizing the stoichiometric ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The present embodiment provides a high-temperature purification method for zinc selenide raw materials, the steps of which are:

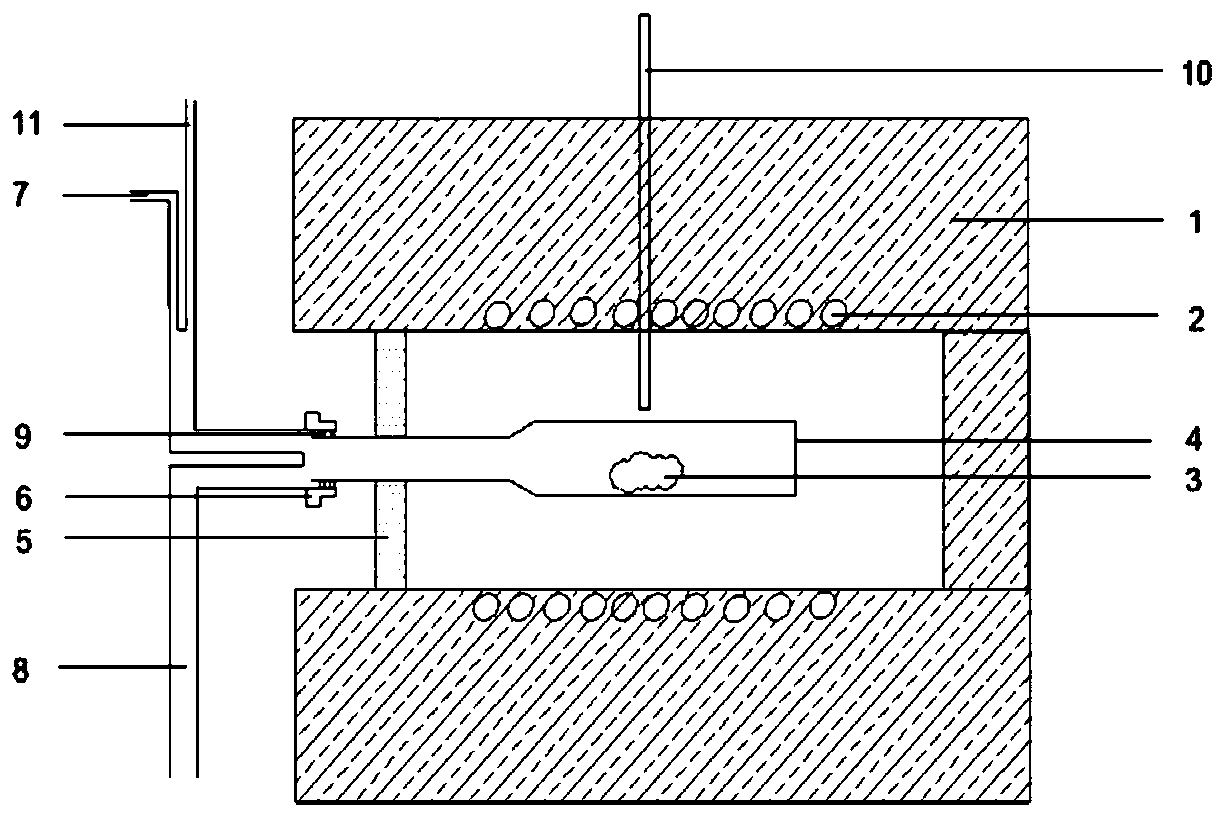

[0046] First, the high-purity quartz crucible 4 is pre-processed, the quartz crucible 4 is put into aqua regia and soaked for 11 hours, then the acid solution attached is rinsed off with deionized water, put into acetone, and ultrasonically cleaned in an ultrasonic cleaner for 30 minutes, and then use Rinse with deionized water to remove the attached acetone, put in deionized water and ultrasonically clean it in an ultrasonic cleaner for 30 minutes, take it out, pour out the deionized water, dry it, then put it into a crystal growth furnace, and install double O-rings 9 Connect the vacuum system 8, the inert gas gas system 7 and the hydrogen gas system 11, close the gas system 7 and the hydrogen gas system 11, open the vacuum system 8 for vacuuming operation, and the vacuum degree reaches 1×10 -5 Below Pa, heat up and heat up to 1100°C at a h...

Embodiment 2

[0054] The present embodiment provides a high-temperature purification method for zinc selenide raw materials, the steps of which are:

[0055] First, the high-purity quartz crucible 4 is pre-processed, the quartz crucible 4 is put into aqua regia and soaked for 8 hours, then the acid solution attached is rinsed off with deionized water, put into acetone, and ultrasonically cleaned in an ultrasonic cleaner for 30 minutes, and then use Rinse with deionized water to remove the attached acetone, put in deionized water and ultrasonically clean it in an ultrasonic cleaner for 30 minutes, take it out, pour out the deionized water, dry it, then put it into a crystal growth furnace, and install double O-rings 9 Connect the vacuum system 8, the inert gas gas system 7 and the hydrogen gas system 11, close the gas system 7 and the hydrogen gas system 11, open the vacuum system 8 for vacuuming operation, and the vacuum degree reaches 1×10 -5 Below Pa, heat up and heat up to 1080°C at a he...

Embodiment 3

[0060] The present embodiment provides a high-temperature purification method for zinc selenide raw materials, the steps of which are:

[0061] First, the high-purity quartz crucible 4 is pre-processed, the quartz crucible 4 is put into aqua regia and soaked for 10 hours, then the acid solution attached is rinsed off with deionized water, put into acetone, and ultrasonically cleaned in an ultrasonic cleaner for 30 minutes, and Rinse with deionized water to remove the attached acetone, put in deionized water and ultrasonically clean it in an ultrasonic cleaner for 30 minutes, take it out, pour out the deionized water, dry it, then put it into a crystal growth furnace, and install double O-rings 9 Connect the vacuum system 8, the inert gas gas system 7 and the hydrogen gas system 11, close the gas system 7 and the hydrogen gas system 11, open the vacuum system 8 for vacuuming operation, and the vacuum degree reaches 1×10 -5 Below Pa, heat up and heat up to 1090°C at a heating ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com